4D-Printed Smart Biomaterials: Engineering Dynamic Tissue Scaffolds for Regenerative Medicine

This article provides a comprehensive analysis of 4D printing for creating intelligent, dynamic tissue scaffolds.

4D-Printed Smart Biomaterials: Engineering Dynamic Tissue Scaffolds for Regenerative Medicine

Abstract

This article provides a comprehensive analysis of 4D printing for creating intelligent, dynamic tissue scaffolds. Aimed at researchers and biomedical engineers, it explores the foundational principles of smart biomaterials (e.g., shape-memory polymers, hydrogels) and their stimuli-responsive behaviors. It details the core methodologies, including material selection, advanced printing techniques (e.g., DLP, extrusion-based), and precise programming for temporal shape transformation. The article addresses critical challenges in printing fidelity, biocompatibility, and degradation control, offering optimization strategies. Finally, it evaluates scaffold performance through in vitro and in vivo validation, comparing 4D printing to static 3D counterparts. The synthesis concludes with future directions for clinical translation in tissue engineering and drug delivery.

What Are Smart Biomaterials? The Science Behind 4D Printing for Tissue Engineering

4D printing is an advanced additive manufacturing (AM) process that creates objects which can change shape, property, or functionality over time in response to specific external stimuli. It integrates smart, stimuli-responsive materials (often biomaterials) with precise 3D printing techniques, where the "fourth dimension" is the time-dependent transformation. Within the thesis context of smart biomaterials for dynamic tissue scaffolds, 4D printing enables the fabrication of scaffolds that can morph, degrade, or activate therapeutic functions post-implantation to better mimic natural tissue dynamics and enhance regeneration.

Table 1: Stimuli-Responsive Mechanisms in 4D Printed Biomaterials

| Stimulus Type | Example Material Class | Typical Response Time (Range) | Shape Change Magnitude (e.g., Bending Angle/Curvature) | Key Application in Tissue Scaffolds |

|---|---|---|---|---|

| Aqueous/Humidity | Hydrogels (alginate, gelatin-methacryloyl, PNIPAM) | 10 sec - 2 hours | 15° - 180° (folding) | Swelling-induced pore size change for cell entrapment/drug release. |

| Temperature | Shape Memory Polymers (PCL, PLA), PNIPAM | 30 sec - 10 min (trigger) | Up to 100% strain recovery | Self-tightening sutures or deployable stents triggered by body heat. |

| pH | Chitosan, PMAA-based hydrogels | 5 - 60 min | Swelling ratio: 1.5 - 4.0 | Drug release in specific inflammatory (acidic) microenvironments. |

| Ionic Strength | Alginate, polyelectrolyte complexes | 2 - 30 min | Variable layer thickness change | Controlled stiffness modulation to guide cell differentiation. |

| Magnetic Field | Ferromagnetic particle-doped polymers | < 1 sec (near instant) | Complex 3D reconfiguration | Remote-controlled scaffold actuation for mechanical conditioning. |

| Enzymatic/Biochemical | Peptide-crosslinked hydrogels | 1 - 24 hours | Degradation-tuned shape change | Cell-responsive scaffold remodeling during tissue growth. |

Table 2: Comparison of 4D Printing Techniques for Biomaterials

| Printing Technique | Compatible Smart Materials | Typical Resolution (XY) | Stimulus Integration Method | Key Advantage for Scaffolds |

|---|---|---|---|---|

| Direct Ink Writing (DIW) | Shear-thinning hydrogels, SMPs | 50 - 500 µm | Multi-material printing for anisotropic response | High cell viability, excellent for soft hydrogels. |

| Stereolithography (SLA/DLP) | Photopolymerizable resins, hydrogels | 10 - 100 µm | Grayscale or multi-wavelength for property gradients | High resolution for micro-architecture. |

| Fused Deposition Modeling (FDM) | SMP filaments (PCL, PU) | 100 - 400 µm | Pre-strain programming during deposition | Robust mechanical structures. |

| Digital Light Processing (DLP) | Bio-inks with photo-initiators | 25 - 100 µm | Voxelated curing for localized stiffness | Fast, high-detail structures. |

| PolyJet/Multi-Material Jetting | Acrylic-based photopolymers, hydrogels | 20 - 50 µm | Multiple print heads for composite voxels | Unparalleled multi-material design. |

Application Notes & Experimental Protocols

Protocol 3.1: Fabrication of a Temperature-Responsive 4D Bilayer Tissue Scaffold

Objective: To print a bilayer scaffold that undergoes rolling/unrolling in response to temperature change, mimicking vascular tissue dynamics.

A. Materials & Pre-Printing Preparation

- Ink A (Active Layer): Poly(N-isopropylacrylamide) (PNIPAM)-based hydrogel prepolymer (25% w/v) with 0.5% LAP photoinitiator. Function: Undergoes significant volume contraction above its Lower Critical Solution Temperature (LCST ~32°C).

- Ink B (Passive Layer): Methacrylated gelatin (GelMA, 15% w/v) with 0.5% LAP. Function: Swells slightly but remains dimensionally stable across 20-37°C, providing a mechanical constraint.

- Equipment: Extrusion-based bioprinter with dual-printhead, UV crosslinking module (365 nm, 5-10 mW/cm²), controlled stage (Peltier plate, 15-45°C).

B. Printing & Programming Workflow

- Model Design: Design a flat, rectangular bilayer construct (20mm x 5mm). The bottom layer (Ink B, 200 µm thick) is 10% wider than the top layer (Ink A, 150 µm thick).

- Printing Parameters:

- Nozzle Diameter: 250 µm.

- Printing Temperature: 20°C (below PNIPAM LCST).

- Print Speed: 8 mm/s.

- Layer-by-layer printing: First, deposit Ink B (Passive). Immediately print Ink A (Active) aligned atop it.

- Simultaneous UV curing after deposition of each full layer.

- Post-Printing: Incubate the flat scaffold in PBS at 20°C for 24h for hydration equilibrium.

C. Activation & Characterization

- Stimulus Application: Transfer scaffold to a PBS bath at 37°C. The PNIPAM layer will dehydrate and contract, while the GelMA layer remains swollen.

- Kinetic Analysis: Record the shape change (rolling into a tube) via time-lapse photography over 10 minutes. Measure the radius of curvature every 30s.

- Cell Studies (Optional): Seed fibroblasts on the scaffold at 20°C (flat state). Raise temperature to 37°C; the rolling action will encapsulate cells, creating a 3D tissue model.

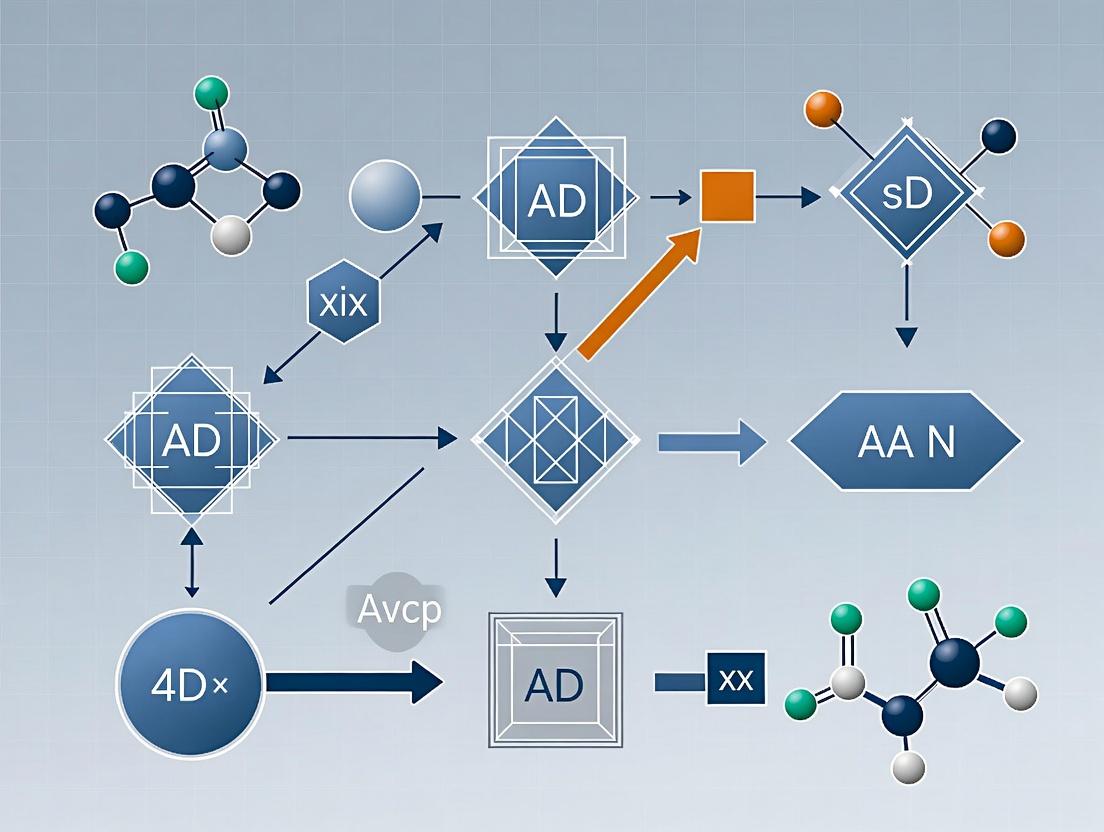

DOT Diagram: 4D Scaffold Printing and Activation Workflow

Protocol 3.2: Enzymatically Triggered Degradation & Shape Change in 4D Printed Scaffolds

Objective: To create a cell-responsive scaffold where matrix metalloproteinase (MMP) activity, indicative of cell remodeling, triggers localized degradation and shape recovery.

A. Materials & Pre-Printing Preparation

- Ink Formulation: MMP-sensitive peptide (e.g., GCGPQGIWGQGCG) crosslinked into a hyaluronic acid methacrylate (HAMA) network. Include 1% w/v LAP photoinitiator.

- Control Ink: Same HAMA network crosslinked with a non-degradable dithiol (PEG-DTT).

B. Printing & Programming Workflow

- Design: Print a compressed, "pre-strained" lattice structure using the MMP-sensitive ink.

- Programming: After printing and initial UV crosslinking, mechanically deform (compress) the scaffold and a second, permanent crosslinking (e.g., with a non-sensitive PEG-diacrylate) is performed to "lock in" the temporary shape.

- Post-Printing: Release the constraint; the scaffold remains in its temporary, compressed shape.

C. Activation & Characterization

- Stimulus Application: Immerse the scaffold in a collagenase solution (2 µg/mL in PBS) or seed with MMP-secreting cells (e.g., mesenchymal stem cells).

- Response: Enzymatic cleavage of the MMP-sensitive crosslinks releases the "locked-in" strain, causing the scaffold to gradually expand to its original, printed shape over 3-7 days.

- Quantification: Measure recovery of height/volume over time. Correlate with MMP activity via fluorometric assays.

DOT Diagram: MMP-Responsive 4D Scaffold Mechanism

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for 4D Printing of Smart Biomaterial Scaffolds

| Reagent/Material | Function in 4D Printing | Example Supplier/Cat. No. (Research-Grade) | Critical Parameters for Protocols |

|---|---|---|---|

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable, biocompatible hydrogel base; passive/active layer component. | Advanced BioMatrix, Sigma-Aldrich | Degree of methacrylation (60-90%), concentration (5-20%). |

| Poly(N-isopropylacrylamide) (PNIPAM) | Temperature-responsive polymer for active layers (LCST ~32°C). | Sigma-Aldrich, Polymersource | Molecular weight, co-monomer type for LCST tuning. |

| Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Highly efficient, biocompatible photoinitiator for UV/VIS crosslinking. | Tokyo Chemical Industry | Concentration (0.1-1.0% w/v), cytocompatibility at low %. |

| MMP-Sensitive Peptide Crosslinker | Provides enzymatic responsiveness for cell-driven scaffold remodeling. | Genscript, Bachem | Peptide sequence (e.g., for MMP-2), solubility. |

| Poly(ε-caprolactone) (PCL) Diol/Diacrylate | Shape Memory Polymer precursor; provides elasticity and programmable temporary shapes. | Sigma-Aldrich, Polysciences | Molecular weight (Mn ~2k-10k), crystallinity. |

| Magnetic Nanoparticles (Fe3O4) | Enables remote actuation via magnetic fields for dynamic mechanical stimulation. | Sigma-Aldrich, nanoComposix | Particle size (20-50 nm), surface coating for dispersion. |

| Rhodamine B Isothiocyanate (RITC)-dextran | Fluorescent tracer for quantifying swelling/deswelling kinetics and diffusion. | Sigma-Aldrich | Molecular weight (e.g., 70kDa), conjugation stability. |

| Poly(ethylene glycol) Diacrylate (PEGDA) | Used as a secondary, permanent crosslinker to "lock in" temporary shapes. | Sigma-Aldrich, Laysan Bio | Mn (575, 3400), functionality. |

Application Notes

Hydrogels

Hydrogels are three-dimensional, hydrophilic polymer networks capable of absorbing large amounts of water or biological fluids. Their high water content, tunable porosity, and biocompatibility make them ideal for mimicking the extracellular matrix (ECM). For 4D-printed dynamic tissue scaffolds, hydrogels can be designed to respond to stimuli (pH, temperature, enzymes) to modulate cell behavior, release therapeutic agents, or gradually degrade to be replaced by native tissue.

Key Applications in 4D Printing:

- Cell-Laden Bioprinting: Encapsulation of living cells (e.g., chondrocytes, stem cells) within bioinks for direct fabrication of tissue constructs. Responsive gels can stiffen post-printing to provide mechanical integrity.

- Drug Release Scaffolds: Printing of hydrogel scaffolds with embedded growth factors (e.g., VEGF, BMP-2) for spatiotemporally controlled release triggered by physiological cues.

- Dynamic Morphing Structures: Printing of bilayer or gradient structures with differential swelling properties, enabling pre-programmed shape changes (e.g., curling tubes) upon immersion in aqueous media.

Shape-Memory Polymers (SMPs)

SMPs are materials that can be deformed from a permanent shape, fixed into a temporary shape, and later recover their original shape upon application of an external stimulus (heat, light, magnetic field). In 4D-printed scaffolds, this allows for minimally invasive implantation (temporary compact shape) and subsequent shape recovery to a complex, functional geometry in vivo.

Key Applications in 4D Printing:

- Self-Fitting Implants: Printing of porous SMP scaffolds in a compact temporary shape for endoscopic delivery; body temperature triggers expansion to fill a tissue defect.

- Mechanically Adaptive Scaffolds: Programming SMPs to change stiffness after implantation—soft for initial integration, then stiff to support load-bearing (e.g., bone).

- Actuating Structures: Creating scaffolds that apply gradual, gentle force to surrounding tissue, useful in applications like mandibular distraction osteogenesis.

Liquid Crystal Elastomers (LCEs)

LCEs combine the molecular order of liquid crystals with the elastic properties of elastomers. This unique combination results in materials capable of large, reversible, and directional shape changes (actuation) in response to heat, light, or other stimuli. They offer precise control over the magnitude and direction of deformation.

Key Applications in 4D Printing:

- Biomimetic Actuators: Printing of LCE scaffolds that mimic the anisotropic contraction of muscle tissue, providing dynamic mechanical cues to seeded myocytes or cardiomyocytes.

- Stimuli-Responsive Pores: Creating pore architectures that open or close in response to specific stimuli (e.g., near-infrared light), enabling controlled cell infiltration or release of metabolites.

- Cellular Mechanotransduction Studies: Fabrication of platforms that cyclically stretch or compress cells in a controlled, programmable manner to study cell response to dynamic mechanical forces.

Table 1: Comparative Properties of Core Smart Biomaterial Classes for 4D Printing

| Property | Hydrogels | Shape-Memory Polymers (SMPs) | Liquid Crystal Elastomers (LCEs) |

|---|---|---|---|

| Primary Stimulus | pH, Temp, Ionic, Light | Heat, Light, Magnetic | Heat, Light (NIR/UV) |

| Key Response | Swell/Shrink, Degrade | Shape Recovery (One-way) | Reversible Actuation |

| Typical Strain | 10-200% (Swelling) | 100-1000% (Recovery) | 20-400% (Actuation) |

| Response Time | Seconds to Hours | Seconds to Minutes | Milliseconds to Seconds |

| Mechanical Modulus (Hydrated) | 0.1 kPa - 10 MPa | 10 MPa - 3 GPa (glassy) | 0.1 - 100 MPa |

| Cell Compatibility | Excellent (High water content) | Good (Surface modification often needed) | Moderate (Requires biofunctionalization) |

| 4D Printability | Excellent (Direct ink writing, stereolithography) | Good (Fused deposition modeling, polyjet) | Emerging (Direct ink writing of LCE inks) |

Experimental Protocols

Protocol: 4D Printing of a Thermoresponsive Bilayer Hydrogel Actuator

Aim: To fabricate a scaffold that undergoes programmed curling upon temperature change, mimicking dynamic tissue environments. Materials: See Scientist's Toolkit section.

Methodology:

- Ink Formulation:

- Prepare Ink A (Passive Layer): 15% w/v GelMA, 0.25% w/v LAP in PBS. Heat at 60°C until fully dissolved. Filter sterilize (0.22 µm).

- Prepare Ink B (Active Layer): 10% w/v PNIPAm (or commercial thermogel), 2% w/v Alginate, 0.25% w/v LAP in culture medium. Dissolve on ice. Filter sterilize.

Printing Setup:

- Use a stereolithography (SLA) or digital light processing (DLP) bioprinter equipped with a dual-vat system or sequential printing capability.

- Set build platform temperature to 15°C.

Printing Process:

- Layer 1 (Active): Load Ink B. Print the first layer pattern using UV light (365 nm, 10 mW/cm² for 15s per 100 µm layer).

- Layer 2 (Passive): Without moving the platform, switch vats to Ink A. Print the second layer pattern directly atop the first (365 nm, 15 mW/cm² for 20s per 100 µm layer).

- Repeat for 10 bilayers to create a rectangular strip (20mm x 5mm x 1mm).

Post-Processing:

- Gently rinse the printed structure in sterile PBS at 15°C to remove unreacted monomers.

- Crosslink the alginate in Ink B by immersing in 100mM CaCl₂ solution for 5 minutes.

- Rinse again with PBS.

4D Actuation Test:

- Immobilize one end of the strip.

- Transfer to a cell culture medium bath at 37°C.

- Record the deformation (curling angle vs. time) using a time-lapse camera over 30 minutes.

- Quantitative Data: Measure the radius of curvature (R) of the strip after equilibrium at 37°C.

Workflow for 4D-Printed Bilayer Hydrogel Actuation

Protocol: Programming a 4D-Printed Shape-Memory Polymer Scaffold

Aim: To create a porous SMP scaffold that can be compressed for implantation and recover its shape at body temperature. Materials: See Scientist's Toolkit section.

Methodology:

- Printing Permanent Shape (Porous Scaffold):

- Load poly(ε-caprolactone) (PCL) or poly(L-lactide-co-trimethylene carbonate) filaments into a fused deposition modeling (FDM) printer.

- Print a 10x10x5mm³ porous scaffold (e.g., 0/90° laydown pattern, 60% porosity, 400 µm strand distance). This defines the permanent shape.

Programming the Temporary Shape:

- Heat the printed scaffold in an oven to Ttrans + 10°C (e.g., 65°C for PCL, Ttrans ~55°C).

- Once soft, apply uniaxial compressive force (using a calibrated mechanical tester) to reduce scaffold height by 70%.

- Hold the strain constant while cooling the scaffold to T_trans - 20°C (e.g., 35°C). This "freezes" the molecular chains in the deformed state.

- Release the load. The scaffold maintains the compressed temporary shape.

Shape Recovery Analysis:

- Place the programmed scaffold in a phosphate-buffered saline (PBS) bath at 37°C.

- Use a camera to record the recovery process.

- Calculate the Shape Recovery Ratio (Rr): Rr(%) = (εm - εt) / εm * 100, where εm is the maximum strain applied during programming, and ε_t is the residual strain at time t.

SMP Programming and Thermal Recovery Cycle

Protocol: Characterizing Photothermal Actuation of a 4D-Printed LCE Scaffold

Aim: To quantify the reversible, light-induced actuation strain of a printed LCE grid scaffold. Materials: See Scientist's Toolkit section.

Methodology:

- Ink Preparation & Printing:

- Use a pre-formulated, photo-polymerizable LCE ink containing mesogens, crosslinkers, and a photoinitiator.

- Load ink into a direct ink writing (DIW) printer with a heated syringe (typically 80-100°C to reduce viscosity).

- Print a simple grid structure (15mm x 15mm, single layer) onto a glass substrate. Maintain print bed at 60°C to align mesogens via shear forces during extrusion.

- Immediately cure the printed filament using UV light (365 nm) to lock in the alignment (monomeric "glassy" state).

Thermal Post-Curing:

- Transfer the printed grid to an oven at 120°C (above the nematic-isotropic transition, T_ni) for 2 hours to complete the crosslinking, establishing the polydomain permanent shape.

Photothermal Actuation Test:

- Clamp one end of the LCE grid. Attach a non-contact video extensometer or use digital image correlation (DIC) software for strain measurement.

- Expose the entire grid to a near-infrared (NIR) laser (808 nm, 1.5 W/cm², 5mm spot diameter, scanning if needed) for 30 seconds.

- The incorporated photothermal agent (e.g., graphene, gold nanorods) converts light to heat, raising the local temperature above T_ni, causing contraction along the nematic director.

- Turn off the laser and allow the grid to cool and recover for 60 seconds.

- Repeat for 10 cycles to assess reversibility and fatigue.

- Quantitative Data: Calculate Actuation Strain (ε): ε(%) = (L0 - L) / L0 * 100, where L_0 is initial length and L is contracted length.

LCE Photothermal Actuation and Recovery Mechanism

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for 4D Printing Smart Biomaterial Scaffolds

| Material/Reagent | Function/Description | Example Supplier/Catalog |

|---|---|---|

| Gelatin Methacryloyl (GelMA) | Photocrosslinkable hydrogel derivative of gelatin; provides cell-adhesive RGD motifs. | Advanced BioMatrix, 7505-50 |

| Poly(N-isopropylacrylamide) (PNIPAm) | Thermoresponsive polymer; undergoes reversible swelling/deswelling at Lower Critical Solution Temperature (LCST ~32°C). | Sigma-Aldrich, 535311 |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Highly efficient, water-soluble photoinitiator for UV (365-405 nm) crosslinking of hydrogels. | TCI Chemicals, L0366 |

| Poly(ε-caprolactone) (PCL) | Biodegradable, thermoplastic polyester; common SMP for FDM printing with T_trans ~55°C. | Corbion, PURASORB PC 12 |

| Poly(L-lactide-co-trimethylene carbonate) (PLLA-TMC) | Amorphous, flexible copolymer with tunable T_g for SMPs; degrades via hydrolysis. | Evonik, RESOMER LT 706 S |

| RM257 / RM82 Mesogens | Diacrylate liquid crystal monomers used to formulate LCE inks; provide mesogenic order. | Wilshire Technologies, WT-257 / WT-82 |

| Gold Nanorods (AuNRs) | Photothermal agent; absorbs NIR light and converts it to localized heat for LCE actuation. | nanoComposix, AUNR-10-800 |

| Alginic Acid Sodium Salt | Ionic polysaccharide; used as a rheology modifier and for secondary ionic crosslinking. | Sigma-Aldrich, A0682 |

| Calcium Chloride (CaCl₂) Solution | Ionic crosslinker for alginate, stabilizing printed hydrogel structures. | Various |

| Digital Light Processing (DLP) BioPrinter | Printer for high-resolution, layer-wise photopolymerization of hydrogel and LCE inks. | BICO (Cellink), Lumen X+ |

| Fused Deposition Modeling (FDM) Printer | Printer for extruding thermoplastic filaments like PCL to create SMP scaffolds. | Ultimaker S5 |

| Near-Infrared (NIR) Laser System | Light source (e.g., 808 nm) for remote, spatiotemporal triggering of photothermal materials. | Thorlabs, CP808TM_1000 |

Within the paradigm of 4D printing for smart biomaterials, dynamic tissue scaffolds are engineered to undergo predefined, time-dependent morphological or functional changes in response to specific environmental cues. These stimuli-responsive mechanisms are foundational for creating biomimetic structures that can guide tissue regeneration in a spatially and temporally controlled manner. This application note details the reaction mechanisms to key stimuli—temperature, pH, moisture, and light—and provides standardized protocols for their characterization, critical for researchers in tissue engineering and drug development.

Temperature-Responsive Mechanisms

Temperature-responsive scaffolds, often based on polymers like poly(N-isopropylacrylamide) (pNIPAM) or poly(ε-caprolactone) (PCL) blends, exhibit a reversible phase transition at a lower critical solution temperature (LCST). Below the LCST, the polymer is hydrophilic and swollen; above it, it becomes hydrophobic and collapses, altering scaffold porosity and stiffness.

Key Application: Controlled cell sheet detachment or drug release triggered by mild hyperthermia.

Protocol 1.1: Characterizing LCST and Swelling Ratio

Objective: To determine the LCST and equilibrium mass swelling ratio (Q) of a printed temperature-responsive scaffold.

Materials:

- Printed scaffold disc (5 mm diameter x 2 mm thickness).

- Phosphate Buffered Saline (PBS), pH 7.4.

- Temperature-controlled water bath with precision ±0.1°C.

- Analytical balance (0.01 mg precision).

- Calibrated thermometer.

Procedure:

- Weigh dry scaffold (W_dry).

- Immerse scaffold in PBS at a starting temperature (e.g., 25°C) for 24 hrs to reach equilibrium swelling.

- Remove scaffold, gently blot surface liquid with filter paper, and immediately weigh (W_swollen).

- Repeat steps 2-3 at increasing temperatures (e.g., 30, 32, 34, 36, 38, 40°C).

- Calculate Q at each temperature: Q = (Wswollen / Wdry).

- Plot Q vs. Temperature. The LCST is identified as the inflection point where Q decreases sharply.

Quantitative Data: Temperature Response

Table 1: Characteristic LCST and Swelling Ratios of Common Temperature-Responsive Polymers.

| Polymer/Blend | Typical LCST (°C) | Q below LCST | Q above LCST | Key Application in Scaffolds |

|---|---|---|---|---|

| pNIPAM | 30-32 | 8-12 | 1.5-2.5 | Cell sheet engineering |

| pNIPAM-co-PEG | 35-38 | 6-9 | 2-3 | Tunable drug release |

| PCL-PEG-PCL Triblock | 40-45 (Tm) | N/A | N/A | Shape-memory bone scaffolds |

| Chitosan/glycerophosphate | ~37 (Gelation) | Sol | Gel | Injectable cell carriers |

Title: Temperature-Responsive Scaffold Mechanism

pH-Responsive Mechanisms

pH-responsive scaffolds incorporate ionizable functional groups (e.g., carboxylic acids or amines) that protonate/deprotonate with environmental pH changes, leading to swelling/deswelling or degradation. This is crucial for targeting pathological sites (e.g., tumor microenvironments, inflamed tissues) or specific organ compartments.

Key Application: Site-specific drug delivery in acidic tumor microenvironments or gastrointestinal tract.

Protocol 2.1: Evaluating pH-Dependent Degradation & Release

Objective: To measure mass loss and model drug release from a pH-sensitive scaffold under different pH conditions.

Materials:

- Scaffold discs loaded with a model drug (e.g., FITC-Dextran).

- Buffer solutions: pH 5.0 (acetate), pH 6.8 (phosphate), pH 7.4 (phosphate).

- Orbital shaker incubator (37°C).

- UV-Vis spectrophotometer or HPLC.

- Lyophilizer.

Procedure:

- Weigh initial dry, loaded scaffolds (W_initial).

- Immerse each scaffold in 5 mL of buffer at desired pH (n=3 per group). Incubate at 37°C with gentle shaking.

- At predetermined time points, withdraw 1 mL of release medium for analysis and replace with fresh pre-warmed buffer.

- Quantify drug concentration via calibrated standard curve.

- After 14 days, retrieve scaffolds, rinse, lyophilize, and weigh final dry mass (W_final).

- Calculate cumulative drug release (%) and mass remaining (%): (Wfinal / Winitial)*100.

Quantitative Data: pH Response

Table 2: Response Profiles of Common pH-Sensitive Polymer Motifs.

| Polymer/Motif | pKa | Swelling/Degradation Trigger pH | Typical Response Time (for full swelling) | Application Context |

|---|---|---|---|---|

| Poly(acrylic acid) (PAA) | ~4.5-5.0 | >5.0 | 2-4 hours | Intestinal delivery |

| Polyethylenimine (PEI) | ~8.5-9.0 | <9.0 | 1-3 hours | Nucleic acid delivery |

| Chitosan (deacetylated) | ~6.5 | <6.5 | 4-8 hours | Wound dressings |

| Poly(β-amino ester) (PBAE) | Tunable (6.5-7.4) | Specific to design | Minutes to hours | Targeted cancer therapy |

Title: pH-Response Logic for Ionic Polymers

Moisture/Water-Responsive Mechanisms

Moisture-responsive scaffolds absorb water, leading to hydrogel formation, swelling, and potential shape change. This is often driven by hydrophilic polymers (e.g., gelatin, alginate) or osmosis-driven actuators. Critical for mimicking hygroscopic tissues or creating self-expanding implants.

Key Application: Self-deploying stents or scaffolds for minimally invasive surgery.

Protocol 3.1: Quantifying Hygroscopic Shape Change Kinetics

Objective: To measure the angular/linear deformation rate of a 4D-printed scaffold upon exposure to aqueous medium.

Materials:

- 4D-printed bilayer strip (active layer: gelatin/pNIPAM, passive layer: PCL).

- Time-lapse imaging setup with controlled humidity chamber.

- Image analysis software (e.g., ImageJ).

- Buffer solution (PBS, 37°C).

Procedure:

- Print a flat, bilayer strip with defined initial angle (θ_initial = 0°).

- Mount strip in chamber and initiate time-lapse recording (1 frame/2 sec).

- Introduce pre-warmed PBS to submerge or create saturated humidity.

- Record until shape stabilizes (θ_final).

- Analyze images to plot bending angle (θ) vs. time.

- Calculate the characteristic swelling-induced bending rate (degrees per second) from the linear region of the curve.

Light-Responsive Mechanisms

Light-responsive scaffolds incorporate chromophores (e.g., spiropyran, gold nanoparticles) that absorb specific wavelengths, generating heat or causing photochemical reactions (cleavage, isomerization). This allows for unprecedented spatiotemporal, non-invasive control.

Key Application: Precise, on-demand remote triggering of drug release or cellular activity with spatial resolution.

Protocol 4.1: Spatially-Resolved Light Triggering & Analysis

Objective: To demonstrate patterned drug release from a light-sensitive scaffold using a photomask.

Materials:

- Scaffold doped with light-sensitive linker (e.g., o-nitrobenzyl ester) conjugated to a fluorescent model drug.

- Laser source (UV, 365 nm) or NIR laser (for plasmonic heating).

- Photomask with desired pattern.

- Fluorescence microscope or gel documentation system.

Procedure:

- Prepare scaffold with photocleavable drug conjugate.

- Place photomask directly on scaffold surface.

- Irradiate entire assembly with appropriate wavelength and power density (e.g., UV, 10 mW/cm² for 5 min).

- Remove mask and wash scaffold gently to remove released drug.

- Image scaffold under fluorescence excitation appropriate for the drug.

- The irradiated (exposed) pattern will show decreased fluorescence due to drug release, while masked areas remain fluorescent.

Quantitative Data: Moisture & Light Response

Table 3: Kinetics and Parameters for Moisture and Light Responses.

| Stimulus & Material | Key Parameter | Typical Value Range | Critical for Design |

|---|---|---|---|

| Moisture: Gelatin/PCL Bilayer | Bending Rate (37°C PBS) | 5-15 °/minute | Layer thickness ratio, Crosslinking density |

| Moisture: Cellulose acetate | Swelling Ratio (Q) at 90% RH | 1.2-1.8 | Degree of acetylation |

| Light (UV): o-NB drug conjugate | Irradiation for 50% Release | 365 nm, 5-10 mW/cm² for 2-5 min | Chromophore density, Scaffold opacity |

| Light (NIR): AuNR-doped hydrogel | Temperature Increase ΔT | 40-50°C after 2 min (808 nm, 1 W/cm²) | AuNR concentration, shape, dispersion |

Title: Light-Responsive Patterning Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Stimuli-Responsive Scaffold Research.

| Item | Function in Research | Example Product/Chemical |

|---|---|---|

| Thermo-responsive Polymer | Base material for LCST-based scaffolds. | Poly(N-isopropylacrylamide) (pNIPAM), Sigma-Aldrich, 415324 |

| Photo-initiator | Enforces polymerization during 3D/4D printing under light. | Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP), BroadPharm, BP-25842 |

| pH-Sensitive Crosslinker | Creates bonds labile in specific pH ranges. | 3,3'-Dithiobis(propanoic dihydrazide) (DTP) for redox/pH sensitivity. |

| Near-Infrared (NIR) Chromophore | Converts NIR light to heat for photothermal response. | Gold Nanorods (AuNRs), 10 nm x 40 nm, nanopartz, A12-10-808 |

| Model Drug for Release Studies | Fluorescent tracer to quantify release kinetics. | Fluorescein isothiocyanate–Dextran (FITC-Dextran), 70 kDa, TdB Labs, FD70 |

| Enzymatic Degradation Agent | Simulates in vivo biodegradation. | Collagenase Type II or Lysozyme, for collagen/chitosan scaffolds. |

| Cell-Adhesive Peptide | Functionalizes scaffold to study cell-response interplay. | RGD peptide sequence, GLY-ARG-GLY-ASP-SER, Bachem, 4023447 |

| Shape Memory Polymer | Base for temperature or hydration-activated 4D shapes. | Poly(ε-caprolactone) (PCL), Mn 50,000, Lactel Absorbable Polymers, B6012-2 |

Application Notes: The Imperative for Dynamic Biomaterials

Native ECM is not a static scaffold but a dynamic, instructive environment that provides biophysical and biochemical cues which evolve in space and time to guide cellular processes such as adhesion, proliferation, differentiation, and matrix remodeling. The overarching thesis of 4D printing smart biomaterials is to create tissue scaffolds that recapitulate this dynamism, where the fourth dimension is time-dependent, predictable change in structure or function post-fabrication. This approach addresses critical limitations in static 3D-printed scaffolds, which fail to mimic the temporal programming inherent in development, healing, and homeostasis.

Key Application Areas:

- Developmental Biology Models: Creating scaffolds with spatially patterned cues that change sequentially to mimic morphogenesis.

- Osteochondral Tissue Engineering: Designing scaffolds that initially support cartilage formation before gradually exposing cues to initiate subchondral bone formation.

- Drug Screening: Providing dynamic mechanical or chemical microenvironments that better model disease progression (e.g., fibrosis, cancer metastasis).

- Programmed Degradation & Remodeling: Engineering scaffolds that degrade at a rate matching neo-tissue formation while gradually releasing bioactive factors.

Table 1: Common Stimuli-Responsive Material Systems for Dynamic ECM Mimicry

| Material Class | Stimulus | Response Mechanism | Typical Response Time | Key Tunable Parameter | Reference (Recent Example) |

|---|---|---|---|---|---|

| Thermoresponsive Polymers (e.g., PNIPAm) | Temperature | Hydration/dehydration shift at LCST causing swelling/collapse. | Seconds to minutes | LCST (32-37°C), crosslink density | (Adv. Funct. Mater. 2023) |

| Photo-responsive Polymers (e.,g., Spiropyran-based) | Light (UV/Vis) | Photoisomerization altering hydrophobicity/ionic state. | Milliseconds to seconds | Wavelength, intensity, exposure duration | (Nat. Commun. 2024) |

| pH-Responsive Hydrogels (e.,g., Chitosan, PAA) | pH | Protonation/deprotonation of ionic groups altering electrostatic interactions. | Minutes | pKa of ionic groups, buffer capacity | (Biomacromolecules 2023) |

| Enzyme-Responsive Peptides | Specific Proteases (e.g., MMPs) | Cleavage of peptide crosslinkers leading to degradation or softening. | Hours to days | Peptide sequence (Km, kcat), concentration | (Sci. Adv. 2023) |

| Magneto-responsive Composites | Magnetic Field | Alignment or heating of embedded particles (e.g., Fe₃O₄) causing strain or thermal transition. | Seconds | Particle concentration, size, field strength | (ACS Appl. Mater. Interfaces 2024) |

| Cell-Responsive Hydrogels | Cell-Generated Forces | Mechanosensitive unfolding of domains (e.g., fibrinogen) exposing cryptic sites. | Hours | Domain unfolding force, ligand density | (Cell 2023) |

Table 2: Measured Cellular Outcomes in Response to Dynamic vs. Static Scaffolds

| Cell Type | Scaffold Type (Dynamic Change) | Key Dynamic Parameter | Measured Outcome (vs. Static Control) | Quantitative Improvement | Study Duration |

|---|---|---|---|---|---|

| hMSCs | Stiffness increase (10 to 30 kPa) via secondary crosslinking | Elastic Modulus | Osteogenic differentiation (Runx2 expression) | 2.8-fold increase* | 14 days |

| Neural Progenitor Cells | RGD peptide gradient formation via light patterning | Ligand Density (0 to 5 mM) | Neurite extension and alignment | Directional outgrowth increased by ~300% | 7 days |

| Chondrocytes | Cyclic compression (10% strain) in agarose hydrogel | Mechanical Strain | GAG production | 40% higher GAG/DNA content* | 28 days |

| Fibroblasts | MMP-degradable hydrogel vs. non-degradable | Degradation Rate (~1 kPa/day loss) | Collagen I deposition & organization | Fibril alignment index increased from 0.2 to 0.7* | 21 days |

| *p < 0.01 vs. static control. |

Experimental Protocols

Protocol 1: 4D Printing of a Thermally-Actuated Bilayer Osteochondral Scaffold

Objective: To fabricate a bilayer scaffold where the chondral layer remains stable at 37°C, while the osseous layer undergoes programmed pore size expansion upon cooling to initiate vascular ingrowth.

Materials:

- Bioink A (Chondral Layer): Methacrylated hyaluronic acid (Me-HA, 3% w/v), gelatin methacryloyl (GelMA, 5% w/v), LAP photoinitiator (0.1% w/v).

- Bioink B (Osseous Layer): Pluronic F127-Diacrylate (25% w/v), nano-hydroxyapatite (nHA, 2% w/v), LAP (0.1% w/v).

- Equipment: Extrusion-based 3D bioprinter with dual-temperature printheads and UV curing system (365 nm, 10 mW/cm²).

Method:

- Bioink Preparation: Prepare Bioink A in PBS, keep at 25°C. Prepare Bioink B in cold PBS (4°C), allow to equilibrate to 15°C for printing.

- Printing Parameters: Set printhead for Bioink A to 25°C, Bioink B to 15°C. Use a 22G nozzle.

- Layer-by-Layer Fabrication: a. Print the bottom osseous layer (10mm x 10mm, 0/90° filament pattern) with Bioink B onto a stage cooled to 10°C. b. Immediately expose the printed layer to UV light for 15 seconds for partial crosslinking. c. Print the top chondral layer directly atop the osseous layer using Bioink A. d. Irradiate the entire construct with UV light for 60 seconds for final crosslinking.

- 4D Transformation: Transfer the construct to a 37°C, cell-culture incubator. Over 48 hours, the Pluronic in Bioink B will dissolve, causing the osseous layer pores to expand from an initial 150 ± 20 µm to 450 ± 50 µm, while the HA/GelMA chondral layer remains dimensionally stable.

- Validation: Use time-lapse microscopy and digital image correlation (DIC) to quantify pore expansion dynamics.

Protocol 2: Assessing MSC Differentiation in a Dynamically Stiffening Hydrogel

Objective: To evaluate mesenchymal stem cell (MSC) fate in response to a hydrogel that stiffens in situ from a soft (∼2 kPa) to a stiff (∼20 kPa) microenvironment, mimicking early osteoid formation.

Materials:

- Hydrogel System: PEG-4MAL (8-arm, 20 kDa) macromer, MMP-degradable crosslinker (KCGPQG↓IWGQCK), RGD adhesive peptide (CGRGDS), and a secondary crosslinker (DTT) for stiffening.

- Cells: Human MSCs (passage 4-6).

Method:

- Hydrogel Formation (Soft State): a. Prepare precursor solution: 5 mM PEG-4MAL, 4 mM MMP-peptide crosslinker, 2 mM RGD peptide in PBS. b. Suspend MSCs in precursor at 5 x 10⁶ cells/mL. c. Pipet 50 µL droplets into molds and incubate at 37°C for 15 min to form initial soft hydrogels (∼2 kPa).

- Dynamic Stiffening: a. At t=24 hours post-encapsulation, add culture medium containing 5 mM DTT to the wells. b. Incubate for 6 hours. DTT will diffuse in and create additional, non-degradable thioether crosslinks, increasing stiffness to ∼20 kPa. Control: Maintain in medium without DTT.

- Analysis: a. Mechanical Testing: Use microindentation or rheology at t=0, 6h, 24h, and 48h post-DTT addition to confirm stiffening. b. Cell Fate: At day 7 and 14, fix samples and perform immunocytochemistry for Runx2 (osteogenesis) and PPARγ (adirogenesis). Quantify expression via qPCR. c. Statistics: Compare dynamic stiffening group to static soft and static stiff controls (n=6, one-way ANOVA).

Visualization Diagrams

Title: The Rationale for 4D Dynamic Scaffolds

Title: General 4D Scaffold Development Workflow

Title: Cell Sensing of Dynamic ECM Cues

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for 4D Biomaterial Research

| Item | Function/Description | Example Vendor/Cat. No. (Representative) |

|---|---|---|

| Methacrylated Natural Polymers (GelMA, HA-MA) | Provides biocompatible, photo-crosslinkable base material with inherent bioactivity. | Advanced BioMatrix (GelMA Kit) or ESI BIO (HyStem-HA) |

| Multi-Arm PEG Derivatives (PEG-n-MAL, PEG-n-Acrylate) | Synthetic, inert backbone for high degree of functionalization and controlled crosslinking. | JenKem Technology (PEG-4-MAL, 20kDa) |

| Photocleavable or Photoinitiators (LAP, Irgacure 2959) | Enables spatial and temporal control of crosslinking via light exposure (UV or visible). | Sigma-Aldrich (Irgacure 2959) or TCI (Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate) |

| MMP-Sensitive Peptide Crosslinkers | Creates hydrogels degradable by specific cell-secreted enzymes (e.g., MMP-2/9), enabling cell-driven remodeling. | Genscript (Custom peptide, e.g., KCGPQG↓IWGQCK) |

| Thermoresponsive Polymers (PNIPAm, Pluronic F127-DA) | Enables shape or property change in response to temperature shifts, useful for self-assembly or actuation. | Sigma-Aldrich (PNIPAm) or BASF (Pluronic F127) |

| Functional Peptides (RGD, IKVAV) | Confers specific cell-adhesion or signaling motifs to synthetic or modified natural polymers. | PeproTech (RGD-SP) |

| Stiffness-Tuning Crosslinkers (e.g., DTT, PEG-dithiol) | Allows for secondary, often irreversible, crosslinking to increase elastic modulus dynamically. | Thermo Fisher (Dithiothreitol, DTT) |

| Fluorescent Microspheres (for strain mapping) | Embedded particles used for tracking local deformations and quantifying dynamic shape changes. | Bangs Laboratories (FluoSpheres, carboxylate-modified) |

Application Notes: Functional Advantages of 4D-Printed Dynamic Scaffolds

Within the thesis on 4D printing of smart biomaterials, the core innovation lies in the temporal dimension. 4D-printed scaffolds are engineered to change their shape, porosity, stiffness, or biochemical presentation in vitro or in vivo in response to specific stimuli (e.g., physiological temperature, pH, enzymatic activity, light). This dynamic capability addresses critical limitations of static 3D-printed scaffolds in regenerative medicine and in vitro modeling.

1.1 Dynamic Cell Guidance and Morphogenesis Static scaffolds offer a fixed topographic landscape. In contrast, 4D scaffolds can sequentially present different guidance cues. For example, a scaffold with a tightly packed structure can expand upon hydration to create new micro-channels, guiding cell migration and organized tissue ingrowth. This is pivotal for vascularization and neural regeneration, where directed sprouting is essential.

1.2 On-Demand Mechanical Signaling Cells sense and respond to substrate stiffness (mechanotransduction). A 4D scaffold can be designed to soften after implantation to mimic the compliance of natural tissue, or to stiffen in response to cell-generated forces, providing feedback that promotes maturation. This dynamic mechanical dialogue is impossible with static constructs.

1.3 Enhanced Host Integration A shape-memory 4D scaffold can be printed in a compact, minimally invasive form, injected or implanted, and then triggered to expand in situ to fill a complex defect. This ensures conformal contact with host tissue, reducing gaps and preventing fibrosis, thereby promoting seamless integration.

Table 1: Quantitative Comparison of Static 3D vs. Dynamic 4D Scaffold Performance

| Performance Metric | Static 3D-Printed Scaffold | 4D-Printed Dynamic Scaffold | Experimental Basis & Reference |

|---|---|---|---|

| Cell Alignment Index | Fixed, typically 0.2-0.4 (moderate alignment) | Can increase from 0.3 to >0.7 post-stimulus | Shape-changing grooves guided fibroblast alignment; measured via F-actin orientation analysis. |

| Vascular Network Length | ~500-800 µm after 14 days | Increased by 40-60% (>1200 µm) with dynamic porosity | Dynamic pore opening increased HUVEC sprouting and network formation. |

| Osteogenic Differentiation (ALP Activity) | Baseline increase of 2-3 fold vs. control | Dynamic stiffening yielded 4-5 fold increase | Scaffold stiffening (20 kPa to 60 kPa) at day 7 enhanced RUNX2 expression and ALP in MSCs. |

| In Vivo Integration (% Tissue In-Growth) | ~45-55% at 4 weeks | ~75-85% at 4 weeks | In situ expanding scaffold reduced fibrous capsule thickness by 50%. |

| Stimulus Response Time | N/A | Shape/Property change within 5 min to 24 hrs | Varies by material (e.g., hydrolytic swelling: hours; light-triggered: minutes). |

Experimental Protocols

2.1 Protocol: Evaluating Dynamic Cell Guidance Using a Shape-Morphing 4D Scaffold

Objective: To assess how a temperature-triggered shape change from a flat sheet to a tubular/ridged structure influences fibroblast alignment and migration.

Materials: See "The Scientist's Toolkit" below. Pre-printing: Prepare a bioink solution of methacrylated gelatin (GelMA, 10% w/v) and poly(ε-caprolactone) (PCL, 5% w/v) in a 9:1 ratio. Add 0.5% (w/v) photoinitiator (LAP). Printing: Use a dual-extrusion bioprinter. Print a flat, rectangular lattice (20mm x 10mm) with the GelMA/PCL composite. Immediately crosslink using 405 nm light (5 mW/cm², 60 sec). Post-printing: Culture NIH/3T3 fibroblasts (seeded at 10,000 cells/cm²) on the flat scaffold in DMEM + 10% FBS at 25°C (below transition) for 24 hrs to allow attachment. Stimulation: Transfer the cell-seeded construct to a 37°C incubator. Observe shape change to a curled/ridged structure over 30 minutes. Analysis:

- Fix and Stain: At 48h post-stimulation, fix with 4% PFA, permeabilize, and stain for F-actin (Phalloidin) and nuclei (DAPI).

- Imaging & Quantification: Acquire confocal z-stacks. Use ImageJ/Fiji with the "Directionality" plugin to calculate an Orientation Order Parameter (0 = random, 1 = perfectly aligned).

2.2 Protocol: Assessing Dynamic Mechanotransduction in Mesenchymal Stem Cells (MSCs)

Objective: To quantify the effect of a light-triggered stiffening hydrogel on MSC osteogenic differentiation.

Materials: See "The Scientist's Toolkit" below. Scaffold Fabrication: Synthesize a dual-crosslink hyaluronic acid (HA) hydrogel. First, prepare thiolated HA (HA-SH) and acrylated HA (HA-Ac). Mix to form a soft, cell-encapsulable network (via Michael addition, ~20 kPa). Add a photodegradable crosslinker (e.g., nitrobenzyl ether-based) and a secondary photoinitiator (Irgacure 2959). Cell Encapsulation: Mix passage 4 human MSCs (1 x 10⁶ cells/mL) into the pre-gel solution. Cast in a disc mold (8mm diameter, 2mm height). Allow to gel for 30 min at 37°C. Culture: Maintain in basal growth medium for 3 days. Dynamic Stimulation: At day 3, expose scaffolds to 365 nm UV light (3 mW/cm², 90 sec) to degrade specific crosslinks and increase effective stiffness to ~60 kPa. Switch half of the scaffolds to osteogenic differentiation medium. Analysis:

- ALP Activity: At day 7 and 14, lyse cells and quantify ALP activity using a pNPP assay, normalized to total DNA content (PicoGreen assay).

- qPCR: At day 10, extract RNA and perform qPCR for osteogenic markers (RUNX2, OPN, OCN).

Visualizations

Diagram 1: Logic of 4D Scaffold Advantages

Diagram 2: Dynamic Cell Guidance Experiment Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Material/Reagent | Function in 4D Scaffold Research | Example Product/Chemical |

|---|---|---|

| Methacrylated Gelatin (GelMA) | Photo-crosslinkable, biocompatible hydrogel base providing cell-adhesive motifs. | GelMA, Sigma-Aldrich or proprietary synthesis. |

| Poly(ε-caprolactone) (PCL) | Provides structural integrity and shape-memory properties; often used in composite inks. | PCL (MW 50-80 kDa), various suppliers. |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | Efficient, water-soluble photoinitiator for visible/UV light crosslinking (biocompatible). | LAP, TCI Chemicals or synthesis per Fairbanks et al. |

| Thiolated & Acrylated Hyaluronic Acid (HA) | Forms soft, tunable hydrogels via Michael addition; backbone for dual-crosslink systems. | Glycosil (Thiol-HA) and Gelin-S (Acrylate-HA) from ESI BIO. |

| Photodegradable Crosslinker | Enables light-triggered softening or (when used in a dual network) stiffening. | Nitrobenzyl ether-based crosslinkers (e.g., NB linker). |

| Irgacure 2959 | UV photoinitiator for secondary crosslinking or degradation reactions. | Irgacure 2959, Sigma-Aldrich. |

| Nucleic Acid Stain (for Quantification) | Quantifies cell number/DNA for normalization of biochemical assays. | Quant-iT PicoGreen dsDNA Assay Kit, Thermo Fisher. |

| ALP Activity Assay Kit | Colorimetric quantification of alkaline phosphatase, an early osteogenic marker. | SensoLyte pNPP Alkaline Phosphatase Assay Kit, AnaSpec. |

How to 4D Print a Dynamic Tissue Scaffold: Techniques, Materials, and Programming

Application Notes: A Framework for 4D-Bioink Design

The development of 4D-printed smart scaffolds necessitates a tripartite optimization of material properties. The ink must first be printable (shear-thinning, rapid recovery, suitable viscosity), then become responsive (to stimuli like temperature, pH, light) post-printing to achieve the 4D shape change, and finally, exhibit biofunctionality (cytocompatibility, biodegradability, bio-instructive signaling) to support dynamic tissue regeneration. The following tables and protocols provide a roadmap for this multi-objective design.

Table 1: Quantitative Comparison of Base Hydrogel Polymers for 4D-Bioinks

| Polymer | Typical Conc. Range | Gelation Mechanism | Printability Score (1-5) | Key Responsiveness | Biofunctionality Notes |

|---|---|---|---|---|---|

| Alginate | 2-4% w/v | Ionic (Ca²⁺) | 4 | pH, ionic strength | Low cell adhesion, requires modification (RGD). |

| Gelatin Methacryloyl (GelMA) | 5-15% w/v | Photo-crosslinking | 5 | Temperature (pre-gel) | Excellent cell adhesion & proliferation. |

| Hyaluronic Acid Methacrylate (HAMA) | 1-3% w/v | Photo-crosslinking | 3 | Enzyme (hyaluronidase) | Native role in ECM, modulates cell migration. |

| Poly(N-isopropylacrylamide) (pNIPAM) | 10-20% w/v | Thermo-precipitation (>32°C) | 2 | Temperature | Inherently thermoresponsive; often copolymerized. |

| Pluronic F127 | 20-30% w/v | Thermo-reversible (shear-thinning) | 5 | Temperature | Excellent printability; low biofunctionality, sacrificial. |

Table 2: Additives for Enhancing Responsiveness and Function

| Additive Type | Example | Function | Typical Loading | Effect on Printability |

|---|---|---|---|---|

| Stimuli-Responsive Particle | Fe₃O₄ Nanoparticles | Magnetic responsiveness; enables remote actuation. | 1-5 mg/mL | Increases viscosity; may require surfactant. |

| Conductive Filler | Graphene Oxide (GO) | Enhances electrical conductivity for electro-responsive scaffolds. | 0.1-1 mg/mL | Can improve structural integrity; concentration critical. |

| Biological Cue | RGD Peptide Sequence | Enhances cell adhesion and integrin signaling. | 0.5-2 mM | Negligible effect on rheology. |

| Enzymatic Crosslinker | Horseradish Peroxidase (HRP)/H₂O₂ | Enables gentle, cell-friendly crosslinking. | 1-5 U/mL HRP | Allows longer working time pre-gelation. |

| Growth Factor Carrier | Heparin-coated Microspheres | Sustained release of VEGF, BMP-2, etc. | 0.1-0.5% v/v | Can act as rheological modifier. |

Experimental Protocols

Protocol 1: Formulation and Rheological Assessment of a Dual-Responsive GelMA-pNIPAM Composite Ink

Objective: To create a bioink that is thermally printable and photo-crosslinkable, with subsequent thermoresponsive behavior.

Materials:

- GelMA (≥ 80% methacrylation)

- pNIPAM polymer or pNIPAM-Acrylate macromer

- Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) photoinitiator

- Phosphate Buffered Saline (PBS)

- Rheometer (cone-plate or parallel plate)

Method:

- Precursor Solution Preparation: Dissolve pNIPAM component (10% w/v) in PBS at 4°C overnight. Separately, dissolve GelMA (10% w/v) in PBS at 37°C.

- Composite Ink Formulation: Mix the two solutions at a 1:1 volume ratio under gentle stirring at 15°C (below pNIPAM LCST). Add LAP photoinitiator to a final concentration of 0.25% w/v. Keep solution on ice.

- Rheological Characterization:

- Shear-Thinning: Perform a steady-state flow sweep from 0.1 to 100 s⁻¹ at 15°C. Record viscosity. Ideal ink should show viscosity drop >50%.

- Recovery Test: Apply high shear (100 s⁻¹ for 30 s), then immediately step down to low shear (0.1 s⁻¹ for 60 s). Measure the percentage of viscosity recovery. Target >90% recovery within 30s.

- Temperature Ramp: Increase temperature from 15°C to 37°C at a constant shear rate (10 s⁻¹). Note the temperature at which storage modulus (G') sharply increases due to pNIPAM phase separation.

Protocol 2: Assessing 4D Shape Morphing and Drug Release Kinetics

Objective: To quantify the time-dependent shape change of a printed scaffold in response to a stimulus and correlate it with the release profile of a model therapeutic.

Materials:

- Optimized composite bioink (from Protocol 1)

- Rhodamine B (model drug)

- Extrusion bioprinter with temperature-controlled stage

- Time-lapse imaging system

- Fluorescence spectrophotometer

Method:

- Scaffold Fabrication: Load ink spiked with 50 µg/mL Rhodamine B into printer cartridge. Print a 20mm x 20mm flat mesh construct onto a cold stage (10°C). Immediately expose to 405 nm light (10 mW/cm², 60 s) for crosslinking.

- 4D Morphing Trigger: Transfer scaffold to pre-warmed (37°C) cell culture medium. Initiate time-lapse imaging from above at 1 frame/minute for 60 minutes.

- Shape Change Analysis: Use ImageJ to track the change in projected area or a specific angle of curvature over time. Calculate the characteristic actuation time (time to reach 90% of final deformation).

- Drug Release Quantification: Simultaneously, collect 100 µL aliquots of the surrounding medium at predetermined time points (0, 15, 30, 60, 120, 240 min). Replace with fresh medium. Measure fluorescence (Ex/Em ~555/580 nm) and correlate release percentage with the degree of shape change plotted over time.

Visualizations

Diagram 1: Bioink Design Logic for 4D Scaffolds

(Title: Bioink Design Workflow for 4D Printing)

Diagram 2: Cell Response to Dynamic Scaffold Cues

(Title: Signaling Pathways in 4D Scaffold-Cell Interaction)

The Scientist's Toolkit: Research Reagent Solutions

| Essential Material | Supplier Examples | Function in 4D-Bioink Research |

|---|---|---|

| GelMA Kit | Advanced BioMatrix, CELLINK, Allevi | Provides consistent, biocompatible photocrosslinkable base polymer for cell-laden printing. |

| LAP Photoinitiator | Sigma-Aldrich, TCI Chemicals | Water-soluble, cytocompatible initiator for visible/UV light crosslinking (< 400 nm). |

| RGD Peptide (GRGDS) | PepTech, Bachem | Functionalization agent to confer cell-adhesive properties to inert polymers like alginate. |

| Heparin-Sepharose Beads | Cytiva, Sigma-Aldrich | For purification and controlled binding/release of heparin-binding growth factors (VEGF, BMP-2). |

| Fe₃O₄ Nanoparticles (10nm, PEG-coated) | Nanocs, Sigma-Aldrich | Additive for magneto-responsive inks, enabling non-contact actuation and potential hyperthermia. |

| Rheometer with Peltier Plate | TA Instruments, Anton Paar | Critical for characterizing shear-thinning, recovery, and temperature-dependent viscoelasticity. |

| UV-Vis-NIR Spectrophotometer | Agilent, Thermo Fisher | Quantifies drug/release agent concentration and can assess dispersion stability of nanoparticles in ink. |

Within the thesis framework of 4D printing for dynamic tissue scaffolds, the selection of printing technology dictates the spatial resolution, material versatility, and ability to encode shape-morphing or functional responses. Extrusion, SLA, and DLP each offer distinct advantages for processing stimuli-responsive "smart" biomaterials (e.g., hydrogels with shape-memory, cell-laden bioinks, or photopolymers with dynamic bonds). These technologies enable the fabrication of scaffolds with intricate 3D architectures that can subsequently transform (the 4th dimension) in response to specific biological or physical triggers, such as hydration, temperature, or enzymatic activity, to better mimic dynamic tissue environments.

Table 1: Quantitative Comparison of Advanced Printing Technologies for Smart Biomaterials

| Parameter | Extrusion-Based | Stereolithography (SLA) | Digital Light Processing (DLP) |

|---|---|---|---|

| Typical Resolution (XY) | 100 - 500 µm | 25 - 150 µm | 10 - 100 µm |

| Typical Resolution (Z) | 50 - 200 µm | 25 - 100 µm | 10 - 50 µm |

| Print Speed | Slow-Medium (1-10 mm³/s) | Medium (layer-by-layer curing) | Fast (full-layer instantaneous cure) |

| Key Material Forms | Thermoplastics, High-viscosity hydrogels, Pastes | Photopolymer resins, Low-viscosity functionalized hydrogels | Photopolymer resins, Ceramic slurries, Hydrogels |

| Biofunctionalization Potential | High (direct cell encapsulation) | Medium-High (biocompatible photoinitiators required) | Medium (similar to SLA, but faster curing may affect cells) |

| Suitability for 4D | Excellent for anisotropic, multi-material structures | Excellent for high-resolution, monomaterial 4D constructs | Excellent for high-speed, high-resolution monolithic 4D parts |

| Key Advantage for Tissue Scaffolds | Multi-material printing, cell viability during printing. | High architectural fidelity, smooth surface finish. | Speed and resolution balance, scalable for high-throughput. |

Experimental Protocols for 4D Biomaterial Scaffold Fabrication

Protocol 3.1: Extrusion Printing of a Shape-Morphing Bilayer Hydrogel Scaffold Objective: To fabricate a dual-material scaffold that undergoes programmable curvature upon hydration. Materials: Alginate (Alg, 4% w/v), Gelatin Methacryloyl (GelMA, 10% w/v), Laponite nanoclay (2% w/v), Calcium chloride (CaCl₂, 100mM), Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP, 0.25% w/v), PBS. Method:

- Ink Preparation:

- Ink A (Active Layer): Mix Alg, Laponite, and 0.1% LAP. Homogenize. This ink swells significantly.

- Ink B (Passive Layer): Synthesize GelMA and mix with 0.25% LAP. This ink swells minimally.

- Printing: Load inks into separate syringes on a multi-head bioprinter. Print a bilayer rectangular mesh (e.g., 15x5 mm) with Ink A as the bottom layer and Ink B as the top. Use a 22G nozzle, 10 mm/s speed, 150 kPa pressure.

- Crosslinking: Immediately post-print, crosslink Alg layer by aerosol spraying with 100mM CaCl₂ for 60s. Then, crosslink the GelMA layer by exposing the entire construct to 405 nm light (10 mW/cm²) for 60s.

- 4D Activation: Immerse the crosslinked scaffold in PBS at 37°C. Observe and record time-lapse shape change (curling) due to differential swelling between layers over 60 minutes.

Protocol 3.2: DLP Printing of a Lattice Scaffold with Enzymatic Degradation Trigger Objective: To create a high-resolution scaffold incorporating an enzyme-cleavable crosslinker for predictable degradation. Materials: Poly(ethylene glycol) diacrylate (PEGDA, 700 Da), Matrix metalloproteinase (MMP)-sensitive peptide crosslinker (GCGPQGIWGQGCG), LAP photoinitiator (0.5% w/v), Tris buffer. Method:

- Resin Formulation: Dissolve MMP-sensitive peptide (8 mM) and LAP in Tris buffer. Add PEGDA to a final concentration of 15% (w/v). Filter sterilize (0.22 µm).

- Digital Mask Preparation: Design a 3D gyroid lattice scaffold (pore size ~300 µm) using CAD software. Slice into 2D layers (25 µm/layer) and generate corresponding bitmap sequences.

- Printing: Pour resin into a DLP printer vat with a fluorinated ethylene propylene (FEP) film. Set exposure parameters: 405 nm light, 15 mW/cm² intensity, 2 s exposure per layer. Print layer-by-layer.

- Post-Processing: Wash printed scaffold in PBS for 5 min to remove uncured resin. Post-cure under blue light for 5 min.

- 4D Degradation: Incubate scaffolds in Tris buffer (control) and buffer containing 100 ng/mL collagenase type II (MMP mimic) at 37°C. Measure mass loss and change in compressive modulus at 1, 3, and 7 days.

Visualization of Experimental Workflows and Signaling Pathways

Title: Workflow for Extrusion and DLP 4D Scaffold Protocols

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for 4D Printing of Smart Tissue Scaffolds

| Reagent/Material | Function in 4D Printing Research | Example Supplier |

|---|---|---|

| Gelatin Methacryloyl (GelMA) | A photocrosslinkable, biocompatible hydrogel base; allows cell adhesion and tunable mechanical properties. | Advanced BioMatrix, Sigma-Aldrich |

| Lithium Phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) | A cytocompatible, water-soluble photoinitiator for UV/blue light crosslinking of bioinks. | TCI Chemicals, Sigma-Aldrich |

| Alginate (Alginic Acid) | A ionic-crosslinkable polysaccharide used for rapid gelation and as a component in shape-morphing systems. | NovaMatrix, Sigma-Aldrich |

| Poly(ethylene glycol) diacrylate (PEGDA) | A bioinert, photopolymerizable macromer; backbone for incorporating cleavable (e.g., MMP-sensitive) crosslinkers. | Sigma-Aldrich, Laysan Bio |

| MMP-Sensitive Peptide Crosslinker | Provides enzymatically degradable sites within hydrogel networks, enabling cell-driven or triggered remodeling. | Bachem, Genscript |

| Laponite XLG Nanoclay | A rheological modifier for extrusion printing; can also influence swelling behavior and mechanical reinforcement. | BYK (BYK Additives), Sigma-Aldrich |

Application Notes: Pre-Stressed 4D Printed Scaffolds for Dynamic Morphogenesis

Table 1: Comparison of Smart Biomaterial Systems for 4D Bioprinting

| Material System | Stimulus | Response Time Scale | Max Strain Induced | Cell Viability Post-Actuation | Key Reference (Year) |

|---|---|---|---|---|---|

| Methacrylated Hyaluronic Acid (MeHA)/Polyethylene Glycol Diacrylate (PEGDA) Composite | Hydration | 5-15 minutes | 45-60% | >85% (hMSCs, 7 days) | Zhang et al. (2023) |

| Alginate-Gelatin Interpenetrating Network (IPN) | Ionic (Ca²⁺) | Seconds to minutes | 25-40% | >90% (NIH/3T3, 24h) | Lee et al. (2024) |

| Poly(N-isopropylacrylamide) (PNIPAAm)-Gelatin | Thermal (32-37°C) | 2-10 minutes | 50-80% | ~80% (C2C12, 72h) | Chen & Smith (2023) |

| Shape Memory Polymer (PCL-PU) | Thermal (40°C) | 1-5 minutes | 100-200% | N/A (acellular) | Rodriguez et al. (2023) |

| Liquid Crystal Elastomer (LCE) Ink | Photothermal | <1 second | 40-55% | Pending | Advanced Materials (2024) |

Table 2: Anisotropic Reinforcement Agents for Composite Design

| Reinforcement Agent | Matrix Material | Concentration Range (w/v%) | Modulus Increase | Anisotropy Ratio (Long./Trans.) | Key Function |

|---|---|---|---|---|---|

| Cellulose Nanofibrils (CNF) | Alginate | 0.5-2.0% | 3-5x | 1.8 - 3.5 | Directional stiffness, pore alignment |

| Graphene Oxide (GO) Sheets | GelMA | 0.1-0.5% | 4-8x | 2.0 - 4.2 | Electrical conductivity, guided cell growth |

| Magnetic Nanoparticles (Fe₃O₄) | PEGDA | 1-5% | 1.5-2x | Programmable via field | Remote actuation, spatial patterning |

| Hydroxyapatite Nanorods (nHA) | Collagen | 10-30% | 2-10x | 1.5 - 2.0 | Biomimetic mineralization, osteoconduction |

| Silk Fibroin Microfibers | PVA | 5-15% | 2-4x | 2.5 - 5.0 | Toughness, sustained drug release |

Experimental Protocols

Protocol: 4D Bioprinting of Pre-Stressed, Anisotropic MeHA/PEGDA Lattices for Chondrogenesis

Objective: To fabricate a bilayer lattice scaffold that undergoes programmed curvature under hydration to mimic developing cartilage morphology.

Materials:

- Bioink A (Active Layer): Methacrylated Hyaluronic Acid (20 mg/mL), Polyethylene Glycol Diacrylate (PEGDA, 10 kDa, 10% w/v), Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP, 0.1% w/v), human Mesenchymal Stem Cells (hMSCs, 5x10^6 cells/mL).

- Bioink B (Passive Constraint Layer): PEGDA (10 kDa, 20% w/v), LAP (0.1% w/v), Cellulose Nanofibrils (CNF, 1.5% w/v).

- Equipment: Extrusion-based bioprinter with UV crosslinking module (365 nm, 5 mW/cm²), 22G tapered nozzle, humidified incubation chamber (37°C, 5% CO₂).

Procedure:

- Bioink Preparation: Prepare Bioinks A and B separately. Sterilize via 0.22 µm filtration (acellular components). Mix cells into Bioink A gently just before printing.

- Printing: Load bioinks into separate printing cartridges. a. Print a 15 mm x 15 mm square lattice (strand spacing 500 µm, layer height 150 µm) using Bioink B. b. Immediately expose to UV light (365 nm, 10 s) for partial crosslinking. c. Align nozzle directly over the first layer. Print an identical lattice pattern using Bioink A. d. Perform final crosslinking with UV light (365 nm, 30 s).

- Post-Printing: Transfer construct to chondrogenic medium (DMEM high glucose, TGF-β3 (10 ng/mL), insulin-transferrin-selenium, dexamethasone).

- Actuation & Culture: Incubate at 37°C, 5% CO₂. Monitor shape change (curvature radius) via time-lapse microscopy over 14 days. Measure actin alignment and collagen II deposition via immunofluorescence at day 7 and 14.

- Analysis: Quantify curvature (κ) using image analysis software (e.g., ImageJ). Compare gene expression (SOX9, ACAN, COL2A1) via qPCR against static control scaffolds.

Protocol: Programming Anisotropic Swelling via Magnetic Field Alignment of Nanocomposites

Objective: To create a scaffold with spatially varying stiffness and swelling behavior by aligning graphene oxide (GO) sheets within a GelMA matrix.

Materials:

- Nanocomposite Bioink: Gelatin Methacryloyl (GelMA, 10% w/v), Graphene Oxide (GO, 0.3% w/v), LAP photoinitiator (0.25% w/v).

- Equipment: Permanent neodymium magnet array (field strength ~300 mT), digital light processing (DLP) printer or stereolithography (SLA) setup.

Procedure:

- Ink Alignment: Dispense the GelMA/GO ink into a printing reservoir. Place the reservoir onto the magnet array for 5 minutes prior to printing to allow GO sheet alignment along the magnetic field lines.

- Digital Printing: Using a DLP printer, project a patterned UV light (405 nm, 15 mW/cm²) to crosslink the aligned ink layer-by-layer (slice thickness 50 µm). Rotate or alter the magnetic field orientation between selected layers to create regions with differing anisotropy.

- Characterization: a. Mechanical Anisotropy: Use a micro-indenter to measure compressive modulus parallel and perpendicular to the last applied magnetic field direction. b. Swelling Ratio: Measure mass change after 24h in PBS, both globally and in region-specific dissected samples. c. Electrical Impedance: Measure impedance along different axes using an impedance analyzer to confirm conductive pathway alignment.

Visualizations

(Workflow: From 4D Printing to Functional Tissue)

(YAP/TAZ Mechanotransduction in 4D Scaffolds)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for 4D Biomaterial Research

| Item | Function & Rationale | Example Product/Catalog |

|---|---|---|

| Methacrylated Hyaluronic Acid (MeHA) | Photo-crosslinkable bioink backbone; provides cell-adhesive motifs and tunable swelling. | "Glycosil" (ESI Bio) or in-house synthesis from HA and methacrylic anhydride. |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Highly efficient, cytocompatible UV photoinitiator for visible light (405 nm) crosslinking. | "LAP Photoinitiator" (Sigma-Aldrich, 900889) or "Bioinitiator 2" (Cellink). |

| Poly(ethylene glycol) Diacrylate (PEGDA, 10 kDa) | Inert, hydrophilic crosslinker; modulates mesh size, stiffness, and swelling kinetics of networks. | "PEGDA 10k" (Sigma-Aldrich, 729094). |

| Gelatin Methacryloyl (GelMA) | Gold-standard photocrosslinkable bioink; provides RGD sites, tunable physical properties. | "GelMA Kit" (Advanced Biomatrix, GMP-50) or "BioGel" (Cellink). |

| Cellulose Nanofibrils (CNF) | Sustainable nanomaterial for anisotropic reinforcement; induces contact guidance. | "CNF Suspension" (University of Maine Process Development Center) or "TEMPO-oxidized CNF" (Nippon Paper). |

| Graphene Oxide (GO) Dispersion | 2D nanomaterial for electrical/mechanical enhancement; alignable via magnetic/electric fields. | "Graphene Oxide, 4 mg/mL dispersion" (Sigma-Aldrich, 796034). |

| Transforming Growth Factor-beta 3 (TGF-β3) | Key cytokine for directing stem cell differentiation towards chondrogenic lineage in 4D scaffolds. | "Human Recombinant TGF-β3" (PeproTech, 100-36E). |

| Verteporfin | Small molecule inhibitor of YAP-TEAD interaction; critical control for validating mechanotransduction studies. | "Verteporfin" (Selleckchem, S1786). |

| Micro-valve Based Bioprinter | Enables precise, multi-material deposition for creating complex pre-stress patterns and composites. | "3D-Bioplotter" (EnvisionTEC/Desktop Health) or "Bio X" (Cellink). |

| Tissue Culture-Compatible Strain Device | Applies controlled, cyclic mechanical strain to 4D scaffolds for in vitro conditioning studies. | "Bose BioDynamic Test Instrument" or "Flexcell" systems. |

Application Notes

This document details application notes and protocols for three key implementations of 4D-printed smart biomaterials, framed within research on dynamic tissue scaffolds. These materials respond to specific physiological stimuli, enabling temporal evolution in structure and function post-implantation.

1. 4D-Printed Vascular Graft with Shape Memory for Anastomosis

- Core Material: Photocrosslinkable poly(ε-caprolactone)-based polyurethane (PCL-PU) blended with graphene oxide (GO).

- Stimulus-Response: Thermal (body temperature, ~37°C) triggers shape recovery from a temporary, minimized implantation shape to a pre-designed tubular graft.

- Key Quantitative Performance:

Parameter Data Significance Shape Recovery Rate (37°C) >96% Ensures complete, reliable deployment in situ. Recovery Time (in PBS, 37°C) 20-30 seconds Rapid deployment minimizes surgical time and ischemia. Tensile Strength (Recovered) 12.5 ± 1.8 MPa Exceeds native artery strength (~1-2 MPa). Elongation at Break 320 ± 25% Provides necessary compliance and suture retention. Endothelial Cell Viability (Day 7) >95% Excellent cytocompatibility for monolayer formation. Platelet Adhesion (vs. control) Reduced by ~60% GO imparts anti-thrombogenic properties.

2. 4D-Printed Cartilage Implant with Mechanical Adaptability

- Core Material: Double-network hydrogel of hyaluronic acid methacrylate (HAMA) and poly(N-isopropylacrylamide) (PNIPAAm).

- Stimulus-Response: Thermoresponsive (PNIPAAm) contracts at body temperature, increasing crosslink density and compressive modulus to match cartilage.

- Key Quantitative Performance:

Parameter Data Significance Storage Modulus (25°C, swollen) 15 ± 2 kPa Soft for minimally invasive insertion. Storage Modulus (37°C, equilibrated) 110 ± 15 kPa Matches native articular cartilage (~100-1000 kPa). Swelling Ratio (25°C to 37°C) Decreases by 65% Volume reduction stabilizes implant in defect. Chondrocyte Proliferation (Day 14) 2.5-fold increase Supports tissue integration and matrix production. Glycosaminoglycan (GAG) Deposition 1.8x higher than static scaffold Enhanced functional matrix synthesis. Frictional Coefficient (vs. cartilage) 0.025 (comparable) Provides lubricious surface for joint movement.

3. 4D-Printed Hydrogel Microneedle Patch for On-Demand Drug Delivery

- Core Material: pH-sensitive methacrylated chitosan (CSMA) and poly(ethylene glycol) diacrylate (PEGDA) bilayer.

- Stimulus-Response: Acidic pH (e.g., in inflamed or tumor microenvironments) triggers swelling and dissolution of CSMA, releasing payload.

- Key Quantitative Performance:

Parameter Data Significance Drug Loading Capacity (Doxorubicin) 4.2 ± 0.3% (w/w) High payload for therapeutic efficacy. Release at pH 7.4 (24h) <15% Minimal leakage in healthy tissue. Release at pH 6.0 (24h) 78 ± 5% Triggered, on-demand release at target site. Microneedle Insertion Force ~0.15 N/needle Painless penetration of stratum corneum. Skin Permeation (pH 6.0 vs. 7.4) 5x higher Enhanced localized delivery. In Vivo Tumor Growth Inhibition 75% (vs. control) Demonstrates therapeutic proof-of-concept.

Experimental Protocols

Protocol 1: Fabrication and Testing of 4D Shape-Memory Vascular Graft Objective: To fabricate a thermally responsive vascular graft and quantify its shape-memory and biological properties.

- Ink Preparation: Dissolve PCL-PU pellets (12% w/v) and GO nanoplatelets (0.5% w/v relative to polymer) in anhydrous dimethylformamide (DMF). Stir at 60°C for 24h.

- 4D Printing & Programming: Print a straight tubular construct (ID: 2mm, wall: 300µm) using a pneumatic extrusion printer (Nozzle: 25G, Pressure: 250kPa, Speed: 5mm/s). UV crosslink (365nm, 10mW/cm², 5min).

- Deformation (Programming): Heat the tube to 70°C (above Tg), manually deform into a temporary folded shape, and cool under constraint to 4°C.

- Shape Recovery Analysis: Immerse the folded graft in PBS at 37°C. Record recovery with a high-speed camera. Calculate Recovery Rate (Rr) as: Rr(%) = (θ₀ - θᵢ)/(θ₀ - θₜ) x 100, where θ are angles of original, temporary, and recovered shapes.

- Mechanical Testing: Perform uniaxial tensile testing on recovered samples (ASTM D638, n=5).

- Biological Assessment: Seed human umbilical vein endothelial cells (HUVECs, 50,000 cells/cm²) on the recovered graft. Assess viability (Live/Dead assay) at days 1, 3, and 7.

Protocol 2: 4D Bioprinting and Maturation of Cartilage Implant Objective: To fabricate a thermoresponsive cartilage implant and evaluate its mechanical evolution and chondrogenic capacity.

- Bioink Formulation: Synthesize HAMA (3% w/v) and mix with PNIPAAm precursor (10% w/v). Add photoinitiator LAP (0.1% w/v) and primary human chondrocytes (10 million cells/mL).

- 4D Bioprinting: Print a 10x10x2mm porous lattice structure (22G nozzle, 15°C print bed). Immediately crosslink with visible blue light (405nm, 5mW/cm², 60s).

- Thermomechanical Characterization: Using a rheometer with a temperature-controlled stage:

- Perform a temperature sweep from 20°C to 40°C at 1°C/min, measuring storage modulus (G').

- Hold at 37°C for 1h to measure equilibrium modulus.

- Dynamic Culture: Culture printed constructs in chondrogenic medium (with TGF-β3) in a bioreactor for 28 days. Maintain at 37°C.

- Histological Analysis: At day 28, fix, section, and stain constructs for GAGs (Safranin-O) and collagen type II (immunohistochemistry).

Protocol 3: Fabrication and Stimuli-Responsive Testing of Drug-Loaded Microneedles Objective: To create a pH-sensitive bilayer microneedle array and characterize its triggered drug release profile.

- Drug-Loaded Layer Preparation: Mix CSMA (5% w/v) in acetate buffer (pH 5.0) with model drug (e.g., Doxorubicin, 2mg/mL). Add photoinitiator (Irgacure 2959, 0.5% w/v).

- Barrier Layer Preparation: Prepare PEGDA (20% w/v in PBS) with the same photoinitiator.

- Micro-Molding & 4D Structuring:

- Fill polydimethylsiloxane (PDMS) microneedle molds with CSMA solution. Centrifuge (3000g, 10min) and UV cure (365nm, 20mW/cm², 2min).

- Back-fill the mold base with PEGDA solution and cure again to form the supporting bilayer patch.

- Demold and dry in a desiccator for 24h.

- In Vitro Release Study: Immerse patches (n=4) in release media (PBS) at pH 7.4 and pH 6.0 at 37°C. Withdraw aliquots at predetermined times. Quantify drug concentration via UV-Vis spectroscopy (480nm for Dox).

- Skin Insertion Test: Use porcine skin mounted on a Franz cell. Apply patch with a standardized force (5N/cm²) for 5min. Visualize insertion channels using methylene blue staining and microscopy.

Visualizations

Title: 4D Vascular Graft Shape Recovery Pathway

Title: 4D Cartilage Implant Fabrication & Maturation Workflow

Title: Logic of pH-Triggered Drug Release from 4D Microneedles

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function / Role in 4D Biomaterial Research |

|---|---|

| Photocrosslinkable Prepolymers (e.g., PCL-PU, GelMA, CSMA) | Form the primary, stimuli-responsive network. Provide structural integrity and enable shape fixation via light curing. |

| Stimuli-Responsive Polymers (e.g., PNIPAAm, pH-sensitive chitosan) | Impart dynamic, reversible responsiveness to temperature or pH, driving the 4D shape or property change. |

| Graphene Oxide (GO) Nanosheets | Nanoadditive that enhances mechanical strength, provides anti-thrombogenicity, and can improve printability. |

| Lithium Phenyl-2,4,6-Trimethylbenzoylphosphinate (LAP) | Biocompatible photoinitiator for visible light crosslinking, essential for cell-laden 4D bioprinting. |

| Transforming Growth Factor-beta 3 (TGF-β3) | Key growth factor in chondrogenic medium to direct mesenchymal stem cell/chondrocyte differentiation and matrix production. |

| Poly(ethylene glycol) diacrylate (PEGDA) | Used as a versatile, biocompatible crosslinker or inert barrier layer to control diffusion and degradation. |

| Dynamic Mechanical Analyzer (DMA) / Rheometer | Instrument for quantifying the thermomechanical properties (shape recovery, modulus change) of 4D materials. |

| PDMS Microneedle Molds | Enable high-resolution replication of microneedle arrays for transdermal drug delivery device fabrication. |

1. Application Notes

4D biofabrication integrates the concept of time as the fourth dimension into bioprinting, creating cell-laden constructs that dynamically change their shape or functionality in response to specific stimuli. Within the thesis on smart biomaterials for dynamic tissue scaffolds, this approach is pivotal for engineering constructs that mimic the temporal and spatial complexity of native tissue development and healing.

1.1. Core Stimuli-Responsive Mechanisms The dynamic transformation of 4D-bioprinted constructs is driven by the material's intrinsic response to environmental cues, which in turn directs cell behavior and tissue maturation.

| Stimulus Type | Example Biomaterial Class | Typical Response Time | Key Cellular Outcome | Target Tissue Application |

|---|---|---|---|---|

| Hydration/Swelling | Alginate, Gelatin Methacryloyl (GelMA), Collagen | Minutes to Hours (5 min - 2 hrs) | Altered mechanical sensing, directed migration | Cartilage, Corneal stroma |

| Temperature | Poly(N-isopropylacrylamide) (pNIPAM), Pluronic F127 | Seconds to Minutes (10 s - 5 min) | Cell sheet detachment, porosity change | Wound dressings, Drug screening |

| pH | Chitosan, Alginate-DOPA | Minutes (2 - 15 min) | Targeted drug release in acidic tumor microenvironments | Cancer models, Gastrointestinal tissues |

| Ionic Strength | Alginate, Silk Fibroin | Seconds to Minutes (30 s - 10 min) | Controlled stiffening/softening | Bone-cartilage interfaces |

| Light (UV/Blue) | GelMA, PEGDA, Photocleavable linkers | Seconds (1 - 60 s) | Spatially controlled gelation or degradation | Vascular networks, Neural guides |

| Magnetic | Magnetic nanoparticle-laden hydrogels (e.g., GelMA-Fe3O4) | Milliseconds to Seconds | Remote mechanical actuation, shear stress application | Cardiac patches, Muscle tissues |