AIBN-Initiated Contact Lens Polymer Synthesis: A Comprehensive Protocol for Drug-Loaded Ophthalmic Materials

This article provides a detailed, current guide to synthesizing advanced contact lens polymers using AIBN (2,2'-Azobis(2-methylpropionitrile)) as a thermal initiator.

AIBN-Initiated Contact Lens Polymer Synthesis: A Comprehensive Protocol for Drug-Loaded Ophthalmic Materials

Abstract

This article provides a detailed, current guide to synthesizing advanced contact lens polymers using AIBN (2,2'-Azobis(2-methylpropionitrile)) as a thermal initiator. Tailored for researchers and drug development professionals, it covers the foundational chemistry of AIBN-initiated free radical polymerization, step-by-step methodological protocols for creating drug-eluting hydrogel lenses, critical troubleshooting for monomer conversion and biocompatibility, and validation techniques against alternative initiators. The scope includes optimizing polymerization conditions, characterizing key material properties (transparency, oxygen permeability, modulus), and strategies for incorporating therapeutic agents for controlled ocular drug delivery.

AIBN in Polymer Science: Core Principles and Rationale for Ophthalmic Biomaterials

Within the context of synthesizing novel contact lens polymers, the selection and understanding of free-radical initiators is paramount. Azobisisobutyronitrile (AIBN) remains a cornerstone reagent for thermal initiation in the polymerization of hydrophilic monomers like 2-hydroxyethyl methacrylate (HEMA) and N-vinylpyrrolidone (NVP). This application note details the quantitative decomposition kinetics, mechanisms, and practical protocols for employing AIBN in controlled, reproducible polymer synthesis for biomedical device research.

Quantitative Decomposition Kinetics of AIBN

The thermal decomposition of AIBN is a first-order reaction, generating two isobutyronitrile radicals and nitrogen gas. The rate is highly temperature-dependent, dictating polymerization initiation rates.

Table 1: Thermodynamic and Kinetic Parameters for AIBN Decomposition

| Parameter | Value | Conditions / Notes |

|---|---|---|

| 10-hour Half-life Temperature (T1/2) | 65 °C | In benzene or toluene |

| Activation Energy (Ea) | 128 kJ/mol | Typical range: 125-130 kJ/mol |

| Frequency Factor (A) | 1.6 x 1015 s-1 | |

| Decomposition Rate Constant (kd) at 70°C | 3.17 x 10-5 s-1 | t1/2 ≈ 6.1 hours |

| Decomposition Rate Constant (kd) at 80°C | 2.52 x 10-4 s-1 | t1/2 ≈ 0.76 hours |

| Volume of N2 per mole AIBN | ~22.4 L (at STP) | Theoretical yield; used in manometric studies |

Mechanism of Initiation and Primary Radical Fate

The initiation pathway involves homolytic cleavage of the weak C-N bond in the azo group. The primary radicals can initiate polymerization or undergo side reactions.

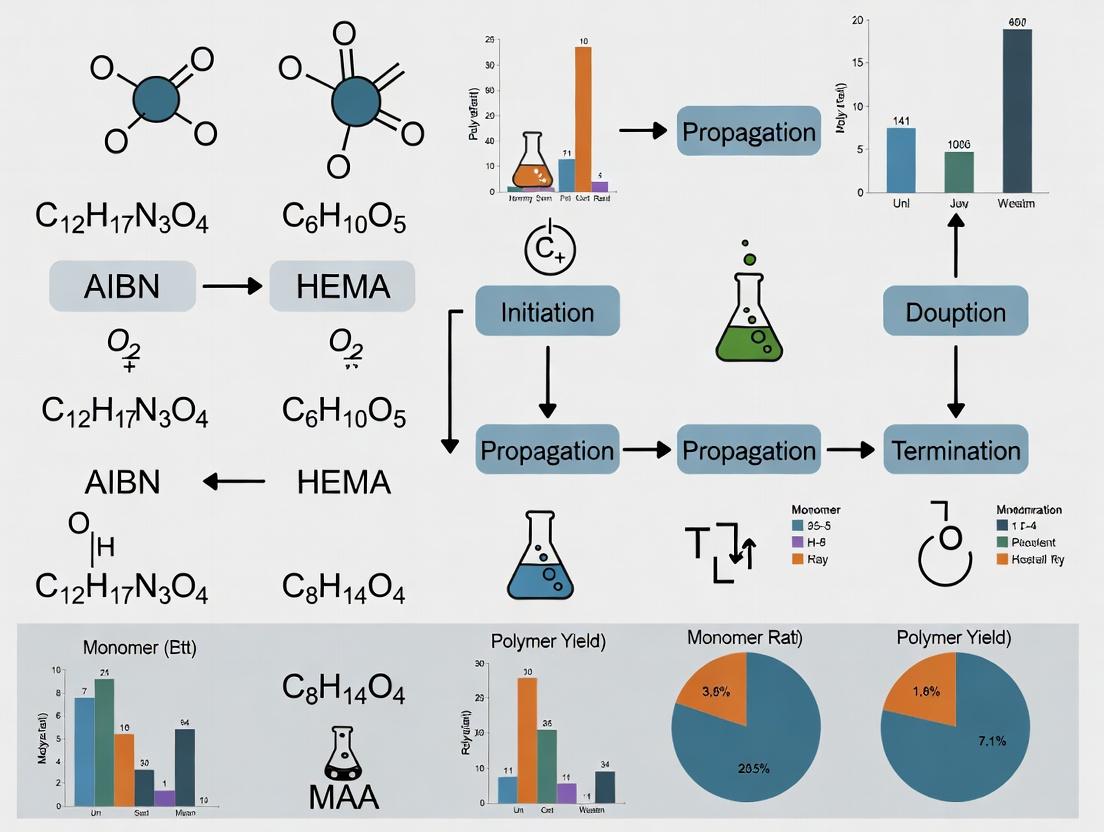

Diagram 1: AIBN thermal decomposition and radical fate pathways.

Experimental Protocols

Protocol 4.1: Determination of AIBN Decomposition Rate Constant (k_d) via Manometry

Principle: Measures volume of nitrogen gas evolved from sealed, degassed AIBN solution at constant temperature.

Materials: See "Scientist's Toolkit" below. Procedure:

- Calibrate the manometer and reaction vessel volume using a known quantity of air.

- Prepare a degassed 0.1 M AIBN solution in dry toluene (50 mL) in a sealed Schlenk flask.

- Using a gas-tight syringe, inject 5.0 mL of the AIBN solution into the pre-evacuated, thermostatted reaction vessel.

- Immerse the vessel in a constant temperature oil bath at the target temperature (e.g., 70.0 ± 0.1 °C).

- Record the manometer pressure increase at regular time intervals.

- Convert pressure to moles of N₂ using the ideal gas law and vessel volume.

- Plot

ln[(V_∞ - V_t)/V_∞]versus time, where V is N₂ volume. The slope equals-k_d.

Safety: Perform behind a blast shield. TMSCN is a toxic byproduct; handle in a fume hood.

Protocol 4.2: Synthesis of HEMA-co-NVP Contact Lens Hydrogel Using AIBN Initiation

Principle: Free-radical copolymerization in a mold to form a crosslinked, hydrophilic network.

Procedure:

- Monomer Mixture: In a vial, mix 78% w/w HEMA, 20% w/w NVP, 1.9% w/w ethylene glycol dimethacrylate (EGDMA, crosslinker), and 0.1% w/w Darocur 1173 (photo-initiator for later curing).

- AIBN Addition: Add AIBN at 0.1% w/w relative to total monomers. Dissolve completely by vortexing.

- Degassing: Sparge the mixture with dry nitrogen or argon for 15 minutes to remove oxygen.

- Molding: Inject the degassed mixture into polypropylene contact lens molds using a syringe.

- Thermal Initiation: Place molds in an oven at 60°C for 4 hours to allow AIBN decomposition and initial polymerization.

- UV Curing: Subject the molds to UV light (365 nm, 5 mW/cm²) for 20 minutes to complete curing via the photo-initiator.

- Extraction: Demold lenses and extract in boiling deionized water for 4 hours to remove unreacted monomers.

- Hydration: Store lenses in sterile phosphate-buffered saline (PBS).

Table 2: Typical Polymerization Formulation & Outcomes

| Component | Function | Weight % | Target Outcome |

|---|---|---|---|

| HEMA | Primary hydrophilic monomer | 78% | High water content, mechanical stability |

| NVP | Co-monomer; enhances wettability | 20% | Increased oxygen permeability |

| EGDMA | Crosslinking agent | 1.9% | Controls hydrogel mesh size & modulus |

| Darocur 1173 | Photo-initiator | 0.1% | Enables final UV cure |

| AIBN | Thermal free-radical initiator | 0.1% | Generates primary radicals at 60°C |

| Final Water Content | - | ~38-42% | Measured gravimetrically |

| Contact Angle | Wettability | 50-55° | Advancing angle in PBS |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for AIBN-Initiated Polymer Synthesis

| Item | Function / Rationale |

|---|---|

| AIBN (Recrystallized) | High-purity initiator ensures reproducible decomposition kinetics. Recrystallize from methanol. |

| Inhibitor-Removed Monomers (HEMA, NVP) | Removal of hydroquinone/MEHQ inhibitors via inhibitor-removal columns is critical for consistent radical propagation rates. |

| Dry, Oxygen-Free Toluene | Solvent for kinetic studies; dryness prevents side reactions, degassing eliminates radical scavenging by O₂. |

| Degassed, Deionized Water | Hydration medium for final polymers; degassing prevents bubble formation within hydrogel matrices. |

| Nitrogen/Argon Gas (High Purity) | Creates an inert atmosphere for degassing monomer mixtures and during thermal polymerization. |

| Polymetric Mold Materials (e.g., PP, PTFE) | Non-stick, inert surfaces that do not inhibit radical polymerization and allow easy demolding. |

| Manometric Setup | Calibrated reaction vessel, manometer, and thermostatic bath for accurate k_d determination. |

| UV Curing Chamber | Provides controlled-intensity UV light (365 nm) for the final curing step in dual-initiation systems. |

Diagram 2: AIBN-initiated contact lens hydrogel synthesis workflow.

Why AIBN for Contact Lenses? Advantages Over UV and Redox Initiators

This application note is framed within a doctoral thesis investigating the systematic optimization of free-radical polymerization for next-generation silicone hydrogel contact lenses. The core thesis posits that initiator selection is the critical, yet underexplored, variable dictating the final polymer network's critical properties: transparency, oxygen transmissibility (Dk), modulus, and biocompatibility. This research compares Azobisisobutyronitrile (AIBN) against ultraviolet (UV) and redox initiator systems, establishing a rigorous experimental framework for synthesis and evaluation.

Comparative Analysis of Initiator Systems

The selection of an initiator fundamentally impacts polymerization kinetics, monomer conversion, and the resultant polymer architecture. The following table summarizes the quantitative and qualitative advantages of AIBN in the contact lens application.

Table 1: Comparative Analysis of Initiator Systems for Hydrogel Synthesis

| Parameter | AIBN (Thermal) | UV Photoinitiators | Redox Initiators (e.g., APS/TEMED) | Advantage Rationale |

|---|---|---|---|---|

| Initiation Mechanism | Thermal decomposition (~65-80°C) | Photolytic cleavage (UV/Blue light) | Electron transfer at ambient temperature | AIBN: Predictable, temperature-controlled kinetics. |

| Radical Generation Rate | Consistent, dependent on temperature & [AIBN]. | Extremely fast, light-intensity dependent. | Very fast, concentration & pH dependent. | AIBN: Enables uniform gelation, minimizing stress gradients. |

| Oxygen Inhibition | Moderate (system is sealed during thermal cure). | Severe (requires inert atmosphere or high intensity). | Low to Moderate. | AIBN: Simplified processing in sealed molds. |

| Byproducts | Nitrogen gas + Tetramethylsuccinonitrile (TSN). | Fragmented photo-bleachable groups. | Salt residues (e.g., sulfates, from APS). | AIBN: N2 gas can create micro-porosity potentially enhancing Dk. TSN must be fully extracted. |

| Process Control | High. Batch-to-batch consistency via time/temp. | High, but dependent on lamp consistency & penetration. | Difficult. Sensitive to trace impurities, pH, temp. | AIBN: Robust, scalable, and reproducible. |

| Final Polymer Purity | High post-extraction (removal of TSN). | Moderate (photo-fragments remain). | Lower (ionic residues persist). | AIBN: Leads to superior biocompatibility and clarity. |

| Typical Monomer Conversion | 95-98% (optimized). | 90-95% (can be limited by oxygen). | 85-95% (variable). | AIBN: Higher conversion reduces residual monomer. |

| Key Disadvantage | Requires thermal cycle; potential for TSN toxicity. | Light penetration limits thickness; oxygen inhibition. | Ionic residues can affect hydration & Dk. | AIBN's drawbacks are manageable via protocol. |

Experimental Protocols

Protocol 3.1: Synthesis of Model Silicone Hydrogel via AIBN-Initiated Polymerization

Objective: To synthesize a transparent, high-Dk hydrogel film using AIBN as the thermal initiator. Materials: See "The Scientist's Toolkit" (Section 5). Procedure:

- Monomer Mixture Preparation: In an amber vial, combine 30 wt% tris(trimethylsiloxy)silyl propyl methacrylate (TRIS), 25 wt% N-vinyl-2-pyrrolidone (NVP), 43.5 wt% 2-hydroxyethyl methacrylate (HEMA), and 1.5 wt% ethylene glycol dimethacrylate (EGDMA). Gently agitate on a roller mixer for 60 min.

- Initiator Addition: Add 0.5 wt% AIBN (relative to total monomers) to the mixture. Continue mixing in the dark for 30 min until fully dissolved.

- Degassing & Molding: Aliquot 1.0 mL of the mixture into a 3 mL syringe. Sparge with nitrogen for 10 min to displace oxygen. Inject the degassed mixture into a clean polypropylene mold consisting of two glass plates separated by a 100 µm Teflon spacer. Seal the mold inlet.

- Thermal Polymerization: Place the sealed mold in a forced-air oven. Cure using the following profile: Ramp from 25°C to 60°C over 30 min, hold at 60°C for 4 hours, then ramp to 90°C over 30 min and hold for 1 hour. This two-stage cure maximizes conversion.

- Demolding & Extraction: Carefully separate the glass plates to release the hydrogel film. Immerse the film in 200 mL of fresh isopropyl alcohol (IPA) for 4 hours to extract unreacted monomers and AIBN byproducts (primarily TSN). Replace with fresh IPA and extract for an additional 4 hours.

- Hydration & Storage: Transfer the film to 200 mL of deionized water for 24 hours, changing the water every 8 hours. Store the hydrated hydrogel in phosphate-buffered saline (PBS) at 4°C.

Protocol 3.2: Extraction Efficiency Quantification of TSN by HPLC

Objective: To verify the removal of toxic AIBN byproduct, tetramethylsuccinonitrile (TSN), from the synthesized hydrogel. Procedure:

- Sample Preparation: Take a 1.0 g slice of the extracted and hydrated hydrogel (from Protocol 3.1). Blot dry with lint-free tissue, place in a vial with 10.0 mL of acetonitrile, and seal. Agitate on an orbital shaker at 25°C for 72 hours to fully leach any residual TSN.

- HPLC Analysis: Analyze the acetonitrile extract using a reverse-phase C18 column. Use an isocratic mobile phase of 50:50 Acetonitrile:Water at 1.0 mL/min. Detect TSN at 210 nm UV. Quantify against a 5-point calibration curve of TSN standard (0.1 - 10 µg/mL).

- Acceptance Criterion: For biomedical application, the residual TSN concentration in the hydrogel must be below 0.1 µg/mL in the extraction solvent, correlating to < 1 ppm in the polymer.

Visualizations

AIBN Hydrogel Synthesis Workflow

Decision Logic for Initiator Selection

The Scientist's Toolkit

Table 2: Essential Research Reagents for AIBN-Initiated Hydrogel Synthesis

| Reagent/Material | Function & Rationale |

|---|---|

| AIBN (2,2'-Azobis(2-methylpropionitrile)) | Thermal free-radical initiator. Decomposes predictably to generate nitrogen and carbon-centered radicals to initiate chain growth. |

| TRIS Monomer | Methacrylated siloxane. Provides silicone content for high oxygen permeability (Dk). |

| NVP (N-Vinyl-2-pyrrolidone) | Hydrophilic monomer. Enhances water content and acts as an internal wetting agent. |

| HEMA (2-Hydroxyethyl methacrylate) | Primary hydrophilic monomer. Forms the hydrogel matrix and provides mechanical stability. |

| EGDMA (Ethylene glycol dimethacrylate) | Crosslinking agent. Creates the polymer network, determining swelling and modulus. |

| IPA (Isopropyl Alcohol) | Extraction solvent. Effectively removes unreacted monomers and hydrophobic byproducts like TSN. |

| Nitrogen Gas (High Purity) | Used for degassing monomer mix to minimize oxygen inhibition prior to thermal cure. |

| Polypropylene Molds with Spacers | Defines the geometry (thickness, curvature) of the final contact lens or test film. |

| HPLC System with C18 Column | Critical for analytical verification of residual monomer and TSN extraction efficiency. |

This application note details key monomers and experimental protocols within the context of a broader thesis investigating AIBN-initiated synthesis of advanced contact lens polymers. The research aims to develop reproducible, high-performance hydrogel formulations with tailored oxygen permeability (Dk), water content (WC), and modulus, leveraging AIBN's predictable decomposition kinetics for controlled radical polymerization.

Key Monomers: Properties and Quantitative Data

Table 1: Core Monomer Properties for Hydrogel Lens Formulation

| Monomer/Chemical | Abbreviation | Primary Function | Typical Wt% in Pre-polymerization Mixture | Key Property Imparted |

|---|---|---|---|---|

| 2-Hydroxyethyl methacrylate | HEMA | Primary hydrogel matrix former | 30-80% | Hydrophilicity, Moderate WC (~38-45%), Good mechanical stability |

| Methacryloxypropyl tris(trimethylsiloxy)silane | TRIS | Siloxane for O₂ permeability | 10-40% | High Dk (>60 barrers), Hydrophobicity |

| N-Vinyl-2-pyrrolidone | NVP | Hydrophilic co-monomer | 5-30% | Increases WC (up to ~70%), Enhances solute diffusion |

| Methacrylic acid | MAA | Functional co-monomer (ionic) | 0.5-5% | Increases WC via ionic hydration, Modifies surface charge |

| Ethylene glycol dimethacrylate | EGDMA | Crosslinker | 0.1-2.5% | Controls mesh size, Modulus, and Swelling Ratio |

| 2,2'-Azobis(2-methylpropionitrile) | AIBN | Radical initiator | 0.1-1% (vs. monomers) | Thermal initiation at ~60-80°C, Predictable half-life |

Table 2: Resulting Polymer Properties from Common Formulations (AIBN-initiated)

| Formulation (HEMA:TRIS:NVP) | AIBN Conc. (%) | Curing Temp (°C) | Water Content (%) | Oxygen Permeability (Dk, barrers) | Tensile Modulus (MPa) |

|---|---|---|---|---|---|

| 100:0:0 | 0.5 | 70 | 38 ± 2 | ~9 | 1.5 ± 0.2 |

| 60:30:10 | 0.5 | 70 | 45 ± 3 | ~45 | 1.0 ± 0.3 |

| 40:40:20 | 0.3 | 80 | 55 ± 4 | ~70 | 0.8 ± 0.2 |

| 50:20:30 | 0.5 | 70 | 65 ± 5 | ~35 | 0.6 ± 0.1 |

Experimental Protocols

Protocol 3.1: Synthesis of Siloxane-Hydrogel Copolymers via AIBN-Initiated Bulk Polymerization

Objective: To synthesize a transparent, high-Dk hydrogel lens material using HEMA, TRIS, NVP, and AIBN.

Materials: See "The Scientist's Toolkit" (Section 5).

Procedure:

- Monomer Purification: Pass HEMA and NVP through inhibitor removal columns. TRIS may be used as received if high purity.

- Pre-polymerization Mixture Preparation: In an amber vial, combine 50 g HEMA, 30 g TRIS, 20 g NVP, and 0.2 g EGDMA. Stir magnetically for 15 min.

- Initiator Addition: Add 0.5 g AIBN to the mixture. Continue stirring in the dark until completely dissolved (~30 min).

- Degassing: Sparge the solution with dry nitrogen or argon for 20 minutes to remove dissolved oxygen, a radical inhibitor.

- Molding & Curing: Using a syringe, inject the mixture into clean polypropylene lens molds. Place molds in a forced-air oven.

- Curing Profile: Ramp from room temperature to 70°C over 30 min. Hold at 70°C for 4 hours (approx. 4x AIBN half-life at this temp).

- Demolding & Extraction: Carefully separate molds. Immerse polymer lenses in 90% v/v ethanol/water for 24h to extract unreacted monomers and oligomers. Refresh solvent once.

- Hydration & Storage: Transfer lenses to sterile phosphate-buffered saline (PBS, pH 7.4) for 48h to equilibrate. Store in PBS at 4°C until characterization.

Protocol 3.2: Determination of Equilibrium Water Content (EWC)

Objective: To accurately measure the water content of synthesized hydrogel lenses.

Procedure:

- Hydration: Equilibrate lens in PBS for >24h.

- Wet Weight (W_w): Blot lens gently with lint-free tissue to remove surface water. Immediately weigh on analytical balance. Repeat for n=5 lenses.

- Dry Weight (W_d): Place lens in a tared desiccator over fresh phosphorus pentoxide (P₂O₅) under vacuum. Dry to constant weight (~72h). Weigh.

- Calculation: EWC (%) = [(Ww - Wd) / W_w] × 100.

Diagrams

Title: AIBN-Initiated Hydrogel Polymerization Workflow

Title: Monomer Impact on Final Hydrogel Properties

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for AIBN-Initiated Lens Synthesis

| Item | Function / Rationale |

|---|---|

| 2-Hydroxyethyl methacrylate (HEMA) | Primary monomer forming the hydrophilic hydrogel matrix; provides foundational structure and ~38-45% water content. Must be purified before use. |

| TRIS-siloxane monomer (e.g., SIGMA) | Imparts high oxygen permeability (Dk) due to siloxane groups; hydrophobic and requires compatible co-monomers. |

| N-Vinyl-2-pyrrolidone (NVP) | Hydrophilic co-monomer to boost equilibrium water content and improve comfort. |

| AIBN (recrystallized) | Thermolabile azo initiator; provides controllable, temperature-dependent radical flux for reproducible polymerization kinetics. |

| Ethylene glycol dimethacrylate (EGDMA) | Crosslinking agent; controls network density, modulus, and swelling ratio. Critical for mechanical integrity. |

| Inhibitor Removal Column | For purifying methacrylate monomers (HEMA) to remove hydroquinone or MEHQ, which impede polymerization. |

| Polypropylene Lens Molds | Inert molds defining lens geometry and curvature during bulk polymerization. |

| Phosphate-Buffered Saline (PBS) | Standard isotonic solution for hydrogel hydration, equilibration, and storage post-synthesis. |

| Nitrogen/Argon Gas Cylinder | For degassing monomer solutions to remove oxygen, a potent radical scavenger. |

| Forced-Air Oven with PID Control | Provides precise, uniform thermal environment for controlled AIBN decomposition and polymerization. |

Application Notes: Critical Material Properties in AIBN-Initiated Contact Lens Polymers

In the synthesis of next-generation contact lens materials using AIBN (2,2'-Azobis(2-methylpropionitrile)) as a radical initiator, three fundamental properties dictate clinical viability: biocompatibility, oxygen permeability (Dk), and wettability. These properties are intrinsically linked to the polymer's chemical structure, which is engineered during synthesis via monomer selection, cross-linker ratio, and processing parameters.

Biocompatibility refers to the material's ability to perform with an appropriate host response in ocular tissue. For AIBN-synthesized hydrogels or silicone hydrogels, this involves minimizing unreacted monomers, residual AIBN initiator fragments, and ensuring leachables are non-cytotoxic. Protocols must rigorously assess epithelial cell viability and inflammatory response.

Oxygen Permeability (Dk) is a quantitative measure (expressed in Barrers) of the material's ability to transmit oxygen to the cornea. In AIBN-initiated systems, high Dk is achieved by incorporating siloxane or fluorinated monomers. However, these hydrophobic components can compromise wettability, creating a design trade-off.

Wettability ensures a stable and comfortable tear film over the lens surface, measured by water contact angle (WCA). Low WCA (<90°) is desirable. Surface modification via plasma treatment or the incorporation of hydrophilic monomers (e.g., 2-hydroxyethyl methacrylate, HEMA) is often required post-polymerization to counteract hydrophobicity from high-Dk components.

The interplay of these properties within an AIBN polymerization framework is summarized below:

Table 1: Target Property Ranges and Associated Monomers for AIBN-Initiated Lens Polymers

| Property | Target Range/Value | Key Influencing Monomers | Measurement Standard |

|---|---|---|---|

| Oxygen Permeability (Dk) | >60 Barrers (Extended Wear) | TRIS, siloxanyl methacrylates, fluoromethacrylates | ISO 18369-4 (Polarographic) |

| Water Contact Angle (WCA) | < 60° (Advancing) | HEMA, N-vinyl pyrrolidone (NVP), methacrylic acid (MAA) | Sessile Drop / Dynamic Advancing |

| Biocompatibility (Cell Viability) | > 90% (vs. control) | N/A (Function of extract purity) | ISO 10993-5 (MTT/XTT Assay) |

| Equilibrium Water Content (EWC) | 20% - 60% | HEMA, NVP, PEGMA | Gravimetric (ISO 18369-3) |

Table 2: Common AIBIBN-Related Reagent Solutions in Lens Synthesis Research

| Research Reagent / Material | Function in Synthesis |

|---|---|

| AIBN (2,2'-Azobis(2-methylpropionitrile)) | Thermal radical initiator; decomposes at ~65-80°C to generate radicals for chain-growth polymerization. |

| TRIS (3-[Tris(trimethylsiloxy)silyl]propyl methacrylate) | Provides high oxygen permeability via siloxane groups; increases hydrophobicity. |

| HEMA (2-Hydroxyethyl methacrylate) | Hydrophilic backbone monomer; increases EWC and wettability. |

| EGDMA (Ethylene glycol dimethacrylate) | Cross-linking agent; controls mesh size, mechanical strength, and affects Dk/EWC. |

| NVP (N-Vinyl-2-pyrrolidone) | Hydrophilic, non-ionic monomer; enhances wettability and EWC. |

| Plasma Gas (e.g., O₂, Ar/CH₄) | For surface modification post-polymerization; creates a permanent hydrophilic coating. |

Experimental Protocols

Protocol 1: Synthesis of a Model Silicone Hydrogel Copolymer via AIBN Initiation

Objective: To synthesize a copolymer with TRIS and HEMA for balanced Dk and wettability. Materials: TRIS, HEMA, EGDMA, AIBN, anhydrous ethanol, nitrogen gas. Procedure:

- In a vial, combine TRIS (50 mol%), HEMA (49.5 mol%), and EGDMA (0.5 mol%).

- Add AIBN initiator at 0.5 wt% relative to total monomers.

- Dissolve the mixture in anhydrous ethanol (monomer:solvent = 1:1 by weight).

- Purge the solution with nitrogen gas for 15 minutes to remove oxygen.

- Inject the solution into a polypropylene mold sealed between glass plates.

- Cure in a thermal oven at 70°C for 12 hours.

- Demold the polymer film and extract in boiling deionized water for 4 hours to remove unreacted species.

- Dry the film under vacuum at 40°C to constant weight before characterization.

Protocol 2: Polarographic Measurement of Oxygen Permeability (Dk)

Objective: To determine the Dk value of a synthesized lens film per ISO 18369-4. Materials: Dk measuring system (e.g., Rehder Development Tank, Createch Polarographic Cell), test sample (0.1-0.2 mm thick), saline, calibration standards. Procedure:

- Hydrate the sample in saline at 35±1°C for at least 24 hours.

- Mount the sample in the measurement cell, separating a saline-filled chamber (with polarographic sensor) from an air-filled chamber.

- Allow the system to equilibrate at 35°C until a stable baseline current is achieved.

- Flush the air-side chamber with pure nitrogen (0% O₂), causing oxygen flux from the sensor side to drop. Record the sensor current decay.

- Switch the gas to pure oxygen (100% O₂). Record the rising sensor current.

- Calculate Dk from the slope of current vs. time data using Fick’s law and instrument-specific software, referencing calibration curves.

Protocol 3: Assessment of Cytocompatibility via MTT Assay (ISO 10993-5)

Objective: To evaluate the in vitro cytotoxicity of extracts from synthesized polymer. Materials: Sterile polymer discs, cell culture medium (without FBS), L929 fibroblast cells, MTT reagent, DMSO, 96-well plate, CO₂ incubator. Procedure:

- Extract Preparation: Sterilize polymer discs (UV light, 1 hr per side). Incubate in serum-free culture medium (3 cm²/mL) at 37°C for 24 hours. Collect extract.

- Cell Seeding: Seed L929 cells at 1x10⁴ cells/well in a 96-well plate. Culture for 24 hours.

- Exposure: Replace medium with 100 µL of extract (100% concentration) or control medium. Incubate for 24-48 hours.

- MTT Assay: Add 10 µL of MTT solution (5 mg/mL) per well. Incubate for 4 hours.

- Solubilization: Carefully remove media, add 100 µL DMSO to dissolve formazan crystals.

- Analysis: Measure absorbance at 570 nm using a plate reader. Calculate cell viability as: (Abssample / Abscontrol) x 100%. Viability > 90% is considered non-cytotoxic.

Protocol 4: Dynamic Advancing Water Contact Angle Measurement

Objective: To quantify the surface wettability of a lens material under simulated blinking conditions. Materials: Contact angle goniometer, motorized syringe, ultra-pure water, hydrated sample mounted on a glass slide. Procedure:

- Hydrate the sample in saline for 24 hours. Blot gently with lint-free tissue to remove surface water.

- Secure the sample horizontally on the goniometer stage.

- Using the motorized syringe, advance a water droplet (~10 µL) onto the sample surface at a rate of 1 µL/s. Capture an image of the droplet the moment the needle tip retracts from the advancing droplet edge.

- Measure the left and right contact angles using software. Report the average as the dynamic advancing contact angle. Perform in triplicate across different surface spots.

Visualizations

AIBN Polymer Synthesis to Key Requirement Workflow

Dk-Wettability Trade-off and Resolution

1. Introduction and Quantitative Data Summary Recent studies leverage AIBN (2,2'-Azobis(2-methylpropionitrile)) as a thermal initiator for synthesizing advanced ophthalmic biomaterials, particularly silicone hydrogel (SiHy) contact lenses. Its decomposition kinetics (T½ ~1 hour at 82°C) enable controlled radical polymerization at moderate temperatures, crucial for incorporating sensitive co-monomers and drug-delivery moieties. The table below summarizes key quantitative findings from recent (2022-2024) research.

Table 1: Recent Studies on AIBN-Initiated Ophthalmic Polymer Synthesis

| Study Focus | Polymer System | AIBN Concentration (wt%) | Key Outcome Metric | Reported Value | Reference Year |

|---|---|---|---|---|---|

| Drug-Eluting Lens | HEMA-co-Siloxane methacrylate | 0.5 | Latanoprost sustained release duration | 14 days in vitro | 2023 |

| High-Oxygen Transmissible SiHy | TRIS-co-DMA | 0.75 | Oxygen Transmissibility (Dk/t) | 145 barrers/mm | 2022 |

| Anti-Fouling Surface | PEGMA grafted on SiHy | 1.0 | Protein Lysozyme Adsorption Reduction | 78% vs. control | 2024 |

| Tear pH-Responsive Lens | HEMA-co-AA (with AIBN) | 0.25 | Swelling Ratio Change (pH 5.8 to 7.4) | 215% increase | 2023 |

| In situ Gelforming Vitreous Substitute | PNIPAAm-co-AAm | 0.3 | Gelation Temperature (Tgel) | 34.5 °C | 2022 |

2. Detailed Experimental Protocols

Protocol 2.1: Standard AIBN-Initiated Synthesis of a Model SiHy Contact Lens Material Objective: To synthesize a silicone hydrogel film for mechanical and transport property evaluation. Materials: See "The Scientist's Toolkit" below. Procedure:

- Monomer Mixture Preparation: In an amber vial, combine 40 wt% mPDMS (1000 Da), 30 wt% DMA, 28.5 wt% HEMA, and 1.5 wt% crosslinker EGDMA. Mix via magnetic stirring for 30 min under N₂ purge.

- Initiator Addition: Add 0.75 wt% AIBN (relative to total monomer weight) to the mixture. Continue stirring at 40°C until AIBN is fully dissolved (~45 min).

- Degassing & Casting: Sonicate the mixture for 15 min under vacuum to remove dissolved oxygen. Using a syringe, inject the mixture into a polypropylene mold consisting of two glass plates separated by a Teflon spacer (150 µm thickness).

- Thermal Polymerization: Place the sealed mold in a forced-air oven. Program the cycle: Ramp from 30°C to 70°C at 1°C/min, hold at 70°C for 2 hours, then ramp to 90°C at 2°C/min and hold for 1 hour.

- Post-Processing: Demold the polymer film. Extract unreacted monomers and oligomers in boiling deionized water for 6 hours, replacing water every 2 hours. Hydrate lenses in phosphate-buffered saline (PBS, pH 7.4) for 24 hours before characterization.

Protocol 2.2: Synthesis of AIBN-Initiated, Drug-Loaded Hydrogel Lenses via Solvent Immersion Objective: To fabricate timolol maleate-loaded contact lenses for sustained release. Procedure:

- Pre-polymer Synthesis: Follow Protocol 2.1 steps 1-4 to synthesize a basic HEMA-co-EGDMA network, using 0.5 wt% AIBN and 1.0 wt% EGDMA.

- Solvent-Assisted Drug Loading: After extraction and drying in vacuo for 48 hours, weigh the xerogel discs (n=10). Immerse them in a 50 mg/mL solution of timolol maleate in ethanol/water (70:30 v/v) at 25°C for 72 hours.

- Re-conditioning: Remove lenses from the drug solution, rinse surface briefly with fresh solvent, and re-hydrate in PBS in a step-gradient manner (25%, 50%, 75%, 100% PBS over 12 hours) to prevent crystallization and control swelling.

- Drug Release Testing: Place individual loaded lenses in 5 mL of simulated tear fluid (STF) at 35°C under mild agitation (60 rpm). At predetermined intervals, withdraw and replace the entire release medium. Analyze timolol concentration via HPLC.

3. Visualizations

Diagram Title: AIBN-Initiated Contact Lens Synthesis Workflow

Diagram Title: AIBN Free Radical Polymerization Mechanism

4. The Scientist's Toolkit: Essential Research Reagents & Materials Table 2: Key Reagent Solutions for AIBN-Initiated Ophthalmic Polymer Research

| Item | Typical Specification/Example | Primary Function in Research |

|---|---|---|

| AIBN Initiator | 98% purity, recrystallized from methanol | Thermal radical source; concentration controls polymer MW and kinetics. |

| Siloxane Monomers (e.g., mPDMS, TRIS) | Monomethacryloxypropyl terminated polydimethylsiloxane (MW 1000 Da) | Imparts oxygen permeability and flexibility to hydrogel matrix. |

| Hydrophilic Co-monomers (e.g., HEMA, DMA, NVP) | 2-Hydroxyethyl methacrylate (HEMA), with stabilizers (MEHQ) removed | Provides hydrogel water content and biocompatibility. |

| Crosslinkers (e.g., EGDMA, TEGDMA) | Ethylene glycol dimethacrylate (EGDMA), 98% | Creates polymer network; determines mesh size and mechanical strength. |

| Functional Monomers (e.g., AA, PEGMA) | Acrylic acid (AA), Poly(ethylene glycol) methacrylate (PEGMA) | Confers responsiveness (pH, hydration) or anti-fouling properties. |

| Extraction Solvent | ACS Grade, deionized water or ethanol/water mix | Removes unreacted monomers, initiator fragments, and oligomers post-polymerization. |

| Hydration Medium | Sterile phosphate-buffered saline (PBS, pH 7.4) or Simulated Tear Fluid (STF) | Conditions lens to physiological state for in vitro testing (release, swelling). |

| Mold Assembly | Glass plates with PTFE/spacer (75-200 µm) or polypropylene concave/convex molds | Defines the final geometry (film, lens curvature) of the biomaterial. |

Step-by-Step Synthesis: Crafting Drug-Eluting Contact Lens Polymers with AIBN

Application Notes

This protocol details the standardized procedure for the free radical bulk polymerization of 2-hydroxyethyl methacrylate (p-HEMA) using 2,2'-Azobis(2-methylpropionitrile) (AIBN) as the thermal initiator. This method is foundational within our broader thesis research on synthesizing and characterizing novel polymeric matrices for ocular drug delivery, specifically in the development of AIBN-initiated contact lens materials. The procedure yields a transparent, crosslinker-free poly-HEMA hydrogel, which serves as a critical baseline material for subsequent modifications, including the incorporation of functional monomers and drug-loading studies. Consistency in this primary synthesis is paramount for ensuring reproducible material properties (e.g., water content, transparency, mechanical strength) in downstream research phases.

Experimental Protocol

Title: Protocol 1: Standard AIBN-Initiated Bulk Polymerization of p-HEMA

Objective: To synthesize poly(2-hydroxyethyl methacrylate) hydrogel via thermal free-radical bulk polymerization.

Principle: AIBN decomposes upon heating to generate nitrogen gas and primary free radicals, which initiate the chain-growth polymerization of the HEMA monomer.

Materials:

- 2-Hydroxyethyl methacrylate (HEMA) monomer, 99%

- 2,2'-Azobis(2-methylpropionitrile) (AIBN), recrystallized

- Methanol, HPLC grade

- Nitrogen gas (N₂), high purity

- Deionized water

Equipment:

- Three-neck round-bottom flask (100 mL)

- Reflux condenser

- Nitrogen inlet/outlet adapter

- Magnetic stirrer with heating oil bath

- Thermometer

- Syringe and needle

- Polypropylene or glass mold (e.g., contact lens mold)

- Vacuum oven

Procedure:

- Initiator Solution Preparation: Weigh 0.1 g of AIBN (0.61 mmol) and dissolve it in 5 mL of methanol. This stock solution provides a convenient means of adding the initiator at a precise concentration.

- Monomer Purification: Pass HEMA monomer (50 mL, 52.6 g, 0.404 mol) through a basic alumina column to remove the hydroquinone monomethyl ether (MEHQ) inhibitor. Use immediately.

- Reaction Setup: Transfer 40 mL (42.1 g, 0.323 mol) of purified HEMA to a clean, dry 100 mL three-neck flask. Equip the flask with a reflux condenser, nitrogen inlet, and thermometer. Place it in a pre-heated oil bath at 65°C.

- Deoxygenation: Under gentle magnetic stirring, purge the system with a steady stream of nitrogen gas for 30 minutes to eliminate dissolved oxygen, a known radical scavenger.

- Initiation: Using a syringe, inject 1.0 mL of the prepared AIBN solution (containing 20 mg AIBN, 0.122 mmol) into the purged HEMA monomer. This results in an initiator concentration of 0.3 mol% relative to monomer.

- Polymerization: Maintain the reaction mixture at 65 ± 1°C under a positive pressure of nitrogen with continuous stirring. Monitor viscosity. The polymerization will proceed to a viscous prepolymer syrup within 25-35 minutes.

- Casting: At the point of increased viscosity but while still pourable (~30 min), carefully pour the prepolymer syrup into pre-cleaned polypropylene lens molds using a syringe. Avoid bubble formation.

- Curing: Seal the molds and transfer them to an oven at 65°C for 24 hours to complete the polymerization.

- Post-Processing: Carefully demold the polymerized p-HEMA hydrogels. Soak them in fresh deionized water for 48 hours, changing the water at least 4 times daily, to extract any unreacted monomer, oligomers, and initiator residues.

- Drying: Blot the hydrated gels dry with lint-free tissue and place them in a vacuum oven at 40°C until constant weight is achieved (typically 48 hours). Store the dried polymer in a desiccator.

Key Quantitative Data

Table 1: Standard Polymerization Formulation and Outcomes

| Component | Amount | Molar Ratio (to Monomer) | Purity/Specification |

|---|---|---|---|

| HEMA Monomer | 40 mL (42.1 g) | 1.000 | Purified via Al₂O₃ column |

| AIBN Initiator | 20 mg | 0.003 (0.3 mol%) | Recrystallized from methanol |

| Reaction Temperature | 65 °C | N/A | ± 1°C control |

| Reaction Time (prepolymer) | 30 min | N/A | Time to casting viscosity |

| Curing Time | 24 h | N/A | At 65°C in mold |

Table 2: Typical Characterized Properties of Synthesized p-HEMA Hydrogel

| Property | Method | Typical Result |

|---|---|---|

| Gel Fraction (%) | Gravimetric analysis after extraction | 98.5 ± 0.5 |

| Equilibrium Water Content (EWC, %) | Gravimetric swelling in DI water | 38.2 ± 1.5 |

| Visible Light Transmittance (%) | UV-Vis Spectrophotometry (λ=550 nm) | >95% |

| Glass Transition Temp (Tg) | Differential Scanning Calorimetry (DSC) | ~110 °C (dry) |

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for AIBN-Initiated Polymer Synthesis

| Item | Function & Critical Notes |

|---|---|

| Inhibitor-Removed HEMA | The monomer must be purified (e.g., via alumina column) to remove polymerization inhibitors (MEHQ) for reproducible kinetics and final molecular weight. |

| Recrystallized AIBN | Thermal initiator. Recrystallization from methanol ensures high purity and reliable half-life (t₁/₂ ~1 hr at 65°C), dictating initiation rate. |

| High-Purity Nitrogen Gas | Essential for creating an inert atmosphere to prevent oxygen inhibition, which can lead to premature termination and low molecular weight. |

| Methanol (HPLC Grade) | Solvent for preparing precise AIBN stock solutions and for recrystallizing AIBN. Anhydrous conditions prevent unwanted side reactions. |

| Deionized Water (18.2 MΩ·cm) | Used for exhaustive extraction of hydrogels. Low ionic purity is critical to prevent contamination that can affect hydrogel swelling and optical properties. |

Visualization

Title: AIBN Initiation and Free Radical Polymerization Mechanism

Title: Bulk Polymerization of p-HEMA Experimental Workflow

Within the broader thesis investigating AIBN (2,2'-Azobis(2-methylpropionitrile)) as a thermal initiator for ophthalmic biomaterials, this protocol details its application as a co-initiator in a redox system for silicone hydrogel synthesis. The research focus is on achieving efficient, low-temperature polymerization crucial for incorporating temperature-sensitive hydrophilic monomers and drugs, thereby advancing towards drug-eluting contact lens platforms. AIBN's role shifts from a primary thermal initiator (studied in other protocols) to a component in a redox pair, enabling rapid cure at physiological temperatures.

Key Research Reagent Solutions

The following table details the essential materials and their functions for this specific co-initiation protocol.

| Reagent/Material | Function & Rationale |

|---|---|

| AIBN | Co-initiator in the redox system. The radical generated from its thermolysis reacts with the reducing agent to produce initiating radicals at an accelerated rate at lower temperatures. |

| Benzoyl Peroxide (BPO) | Primary oxidant in the redox pair. Provides the peroxide moiety essential for the redox reaction with the amine co-monomer. |

| N,N-Dimethylacrylamide (DMA) | Primary hydrophilic co-monomer. Serves a dual function: 1) Imparts hydrogel water content. 2) Acts as the reducing agent (amine) for the BPO/AIBN redox system. |

| TRIS (3-[Tris(trimethylsiloxy)silyl]propyl methacrylate) | Silicone-based macromonomer. Provides oxygen permeability and polymer backbone flexibility. |

| n-Hexanol | Diluent/Porogen. Creates a porous polymer network via polymerization-induced phase separation, leading to enhanced final hydrogel water content. |

| Norbloc (2-(2'-hydroxy-5-methacrylyloxyethylphenyl)-2H-benzotriazole) | UV-absorbing monomer. Critical for incorporating UV-blocking capability into the lens material. |

| Ethylene Glycol Dimethacrylate (EGDMA) | Crosslinking agent. Controls the mesh size and mechanical strength of the hydrogel network. |

Detailed Experimental Protocol

Objective: To synthesize a silicone hydrogel film via redox polymerization using BPO/AIBN/DMA, characterizing its basic physicochemical properties.

Part A: Monomer Mixture Preparation

- In a clean amber vial, combine the following monomers by weight under subdued light:

- TRIS: 50 parts

- DMA: 30 parts

- Norbloc: 2 parts

- Add the diluent and crosslinker:

- n-Hexanol: 20 parts

- EGDMA: 0.5 parts

- Add the initiator system and homogenize:

- Benzoyl Peroxide (BPO): 0.5 parts

- AIBN: 0.1 parts

- Cap the vial and mix on a rotary mixer or vortex agitator for a minimum of 60 minutes until a homogeneous, clear solution is achieved.

Part B: Film Polymerization & Processing

- Assemble a mold consisting of two treated glass plates separated by a polypropylene spacer (thickness: 150 ± 20 µm).

- Using a syringe, inject the monomer mixture into the mold cavity, avoiding bubble entrapment.

- Place the filled mold in an oven pre-heated to 60°C for 120 minutes to effect polymerization.

- After curing, disassemble the mold to retrieve the polymer film.

- Extract the film in refluxing ethanol (≥ 4 hours) to remove unreacted monomers, diluent, and initiator residues.

- Hydrate the extracted film in purified water (≥ 12 hours) to equilibrium. Pat dry with a lint-free cloth before characterization.

Part C: Basic Characterization (Example Data)

| Property | Method | Typical Result (This Protocol) | Comparative Note (Thermal AIBN at 80°C) |

|---|---|---|---|

| Polymerization Time | - | 120 min @ 60°C | ~30 min @ 80°C |

| Final Water Content (%) | Gravimetric (ISO 18369-4) | 52 ± 3 | 48 ± 4 |

| *Oxygen Permeability (Dk) | Polarographic (ISO 18369-4) | 65 ± 5 | 70 ± 5 |

| Transparency (%T) | UV-Vis Spectrophotometry | >95% (500 nm) | >96% (500 nm) |

| Elastic Modulus (MPa) | Tensile Testing (ISO 18369-3) | 0.8 ± 0.2 | 1.1 ± 0.2 |

*Dk units: (10⁻¹¹)(cm²/s)[mLO₂/(mL·mmHg)]

Visualized Workflow and Mechanism

Title: Silicone Hydrogel Synthesis and Processing Workflow

Title: BPO/AIBN/DMA Redox Initiation Mechanism

Within the broader thesis on AIBN-initiated polymer synthesis for contact lens materials, a critical sub-inquiry involves the controlled integration and release of therapeutic agents (e.g., timolol for glaucoma, ketotifen for allergies). This application note compares two principal functionalization strategies—Molecular Imprinting (MI) and Physical Entrapment (PE)—detailing their protocols, performance data, and relevance to smart ophthalmic device development.

Table 1: Core Characteristics of Integration Strategies

| Parameter | Molecular Imprinting (MI) | Physical Entrapment (PE) |

|---|---|---|

| Integration Mechanism | Pre-polymerization complex with functional monomers, cross-linker, and template drug, followed by template extraction. | Drug dispersed in monomer mixture or soaked into pre-formed hydrogel matrix. |

| Polymerization Initiator | AIBN (0.2-1 wt%) thermal initiation at 60-70°C. | AIBN (0.2-1 wt%) thermal or photo-initiation. |

| Key Advantage | Creates specific, complementary binding cavities for the target molecule, enabling selective re-binding and sustained release. | Simple, versatile, suitable for a wide range of drugs without complex chemistry. |

| Key Limitation | Template leaching can be inefficient; process is drug-specific. | Burst release common; lower control over release kinetics. |

| Typical Drug Loading Efficiency | 85-98% (post-rebinding) | 70-95% |

| Release Profile | Sustained, near-zero-order kinetics over days to weeks. | Initial burst (40-60% in first few hours), followed by diffusion-based decay. |

Table 2: Performance Data from Recent Studies (Model Drug: Timolol Maleate)

| Strategy | Polymer Matrix (AIBN-initiated) | Loading Capacity (µg/mg polymer) | Cumulative Release at 24h (%) | Total Release Duration | Reference Year |

|---|---|---|---|---|---|

| MI | HEMA-co-EGDMA | 12.5 ± 1.2 | 15 ± 3 | 14 days | 2023 |

| PE (Soaking) | HEMA-co-NVP | 18.3 ± 2.1 | 65 ± 5 | 3 days | 2024 |

| PE (In-situ) | Silicone Hydrogel | 22.0 ± 1.8 | 80 ± 7 | 2 days | 2023 |

Experimental Protocols

Protocol 3.1: Molecular Imprinting of Timolol in pHEMA-based Contact Lens

Objective: Synthesize timolol-imprinted contact lenses with sustained release profiles.

Research Reagent Solutions & Materials:

| Item | Function |

|---|---|

| 2-Hydroxyethyl methacrylate (HEMA) | Primary hydrogel-forming monomer. |

| Ethylene glycol dimethacrylate (EGDMA) | Cross-linking agent for cavity stability. |

| Timolol maleate | Template/therapeutic drug molecule. |

| Methacrylic acid (MAA) | Functional monomer to interact with template via H-bonding. |

| AIBN (Azobisisobutyronitrile) | Thermal free-radical initiator for polymerization. |

| Dimethyl sulfoxide (DMSO) | Porogenic solvent to enhance cavity formation. |

| Acetic acid/Methanol (9:1 v/v) | Extraction solvent for template removal. |

| Phosphate Buffered Saline (PBS, pH 7.4) | Release study medium. |

Procedure:

- Pre-polymerization Complex Formation: Dissolve timolol maleate (0.05 mmol) and MAA (0.2 mmol) in 2 mL DMSO. Allow to stir for 1 hour at room temperature.

- Monomer Mixture Preparation: To the complex, add HEMA (4.0 mL) and EGDMA (0.5 mL). Mix thoroughly.

- Initiation: Add AIBN (20 mg, 0.5 wt% relative to monomers). Sonicate until fully dissolved.

- Polymerization: Degas the mixture with nitrogen for 5 minutes. Inject into contact lens molds. Thermally polymerize in an oven at 65°C for 12 hours.

- Template Extraction: Demold lenses and immerse in acetic acid/methanol solution (200 mL) for 48 hours, refreshing the solvent every 12 hours. Follow with PBS soaking for 24 hours to remove residual solvents.

- Rebinding & Release: For loading, immerse extracted lenses in a 2 mg/mL timolol-PBS solution for 48 hours. For release studies, transfer loaded lenses to vials containing 5 mL fresh PBS at 34°C under gentle agitation. Analyze aliquot drug concentration via HPLC at predetermined intervals.

Protocol 3.2: Physical Entrapment via In-Situ Dispersion

Objective: Incorporate ketotifen fumarate into a silicone hydrogel lens via direct dispersion.

Research Reagent Solutions & Materials:

| Item | Function |

|---|---|

| TRIS (3-[Tris(trimethylsiloxy)silyl]propyl methacrylate) | Silicone-containing monomer for oxygen permeability. |

| N-Vinyl-2-pyrrolidone (NVP) | Hydrophilic co-monomer for wettability and water content. |

| Ketotifen fumarate | Model antihistamine drug. |

| AIBN | Thermal initiator. |

| n-Hexanol | Non-reactive solvent to create pore network. |

| PBS (pH 7.4) | Release medium. |

Procedure:

- Drug Dispersion: Finely grind ketotifen fumarate (3 wt% relative to total monomers). Add to a mixture of TRIS (2.0 mL), NVP (1.0 mL), and n-hexanol (1.5 mL). Sonicate vigorously for 30 minutes to create a homogeneous dispersion.

- Initiation & Polymerization: Add AIBN (15 mg, 0.5 wt%). Degas with nitrogen. Inject into lens molds and cure at 70°C for 10 hours.

- Post-processing: Demold lenses. Wash in PBS for 24 hours to remove n-hexanol and any surface-bound drug, refreshing PBS 3 times.

- Release Study: Place lenses in 5 mL PBS at 34°C under agitation. Sample and analyze via UV-Vis spectroscopy at 301 nm periodically.

Visualization Diagrams

Diagram 1: Molecular Imprinting Synthesis and Loading Workflow

Diagram 2: Physical Entrapment Drug Release Mechanisms

Within the broader research context of AIBN-initiated hydrogel synthesis for advanced contact lens applications, post-polymerization processing is critical for transforming a polymerized network into a safe, functional, and biocompatible device. This stage directly impacts critical performance parameters such as optical clarity, oxygen transmissibility (Dk), modulus, and overall biocompatibility. The following application notes and protocols detail standardized procedures for the extraction of residual monomers and initiator fragments, hydration, and terminal sterilization, specifically for polymers derived from AIBN-initiated systems.

Application Notes & Protocols

Protocol: Solvent Extraction of Unreacted Monomers and AIBN By-Products

Objective: To remove unreacted monomers, oligomers, and AIBN decomposition products (e.g., tetramethylsuccinonitrile) from the polymerized contact lens matrix.

Principle: A solvent exchange process utilizing increasing polarity gradients effectively extracts hydrophobic and hydrophilic residues without inducing excessive matrix swelling or cracking.

Materials:

- Polymerized, dry contact lens blanks (from AIBN-initiated polymerization).

- Anhydrous Isopropanol (IPA), HPLC Grade.

- Deionized (DI) Water, 18.2 MΩ·cm.

- Heated Ultrasonic Bath (40 kHz).

- Orbital Shaker.

- Analytical Balance.

- Glass Vials with Teflon-lined caps.

Detailed Methodology:

- Weighing: Record the dry mass (M_dry) of each lens blank.

- Primary Extraction (IPA): Immerse lenses in anhydrous IPA (10 mL per lens) in sealed vials. Place on an orbital shaker at 120 rpm for 120 minutes at 25°C.

- Secondary Extraction (IPA/Water): Replace IPA with a 50:50 (v/v) mixture of IPA and DI water. Shake for 60 minutes.

- Tertiary Extraction (DI Water): Replace with 100% DI water. Shake for 60 minutes. Repeat this step with fresh DI water twice more (total of 3 DI water baths, 180 minutes).

- Final Rinse: Perform a final ultrasonic bath in fresh DI water for 10 minutes at 30°C to dislodge any particulate matter.

- Validation: Monitor extraction efficiency by GC-MS analysis of extraction solvents for signature monomers (e.g., HEMA, EGDMA) and AIBN-derived compounds.

Table 1: Typical Extraction Efficiency for AIBN-Initiated pHEMA-based Polymer

| Target Compound | Initial Conc. in Polymer (µg/g) | Post-Extraction Conc. (µg/g) | % Removal |

|---|---|---|---|

| HEMA Monomer | 450 ± 35 | 12 ± 3 | 97.3 |

| AIBN Residue | 85 ± 15 | < 5 (LOQ) | > 94.1 |

| EGDMA Crosslinker | 120 ± 20 | 8 ± 2 | 93.3 |

Protocol: Controlled Hydration and Equilibration

Objective: To gradually introduce water into the extracted polymer network, achieving equilibrium water content (EWC) without inducing stress fractures or optical distortions.

Principle: A stepwise increase in water activity allows for controlled relaxation of the polymer chains, promoting uniform swelling.

Materials:

- Extracted lens blanks.

- Phosphate Buffered Saline (PBS), 0.01M, pH 7.4 ± 0.1.

- Graded Ethanol Solutions (70%, 50%, 25% in PBS).

- Temperature-Controlled Water Bath (60°C).

- Refractometer.

Detailed Methodology:

- Initial Swelling: Transfer extracted lenses from the final DI water bath into a 25% Ethanol/PBS solution. Hold for 30 minutes at 25°C.

- Gradient Steps: Sequentially move lenses to 50% and then 70% Ethanol/PBS solutions, holding for 30 minutes each.

- Transition to PBS: Transfer lenses to 100% PBS. Place the sealed containers in a 60°C water bath for 120 minutes. This heat step aids in complete equilibration.

- Cooling & Storage: Remove the containers and allow them to cool to room temperature (approx. 2 hours). Store lenses in fresh PBS at 4°C until characterization or sterilization.

- EWC Determination: Pat a hydrated lens with lint-free paper, weigh immediately (Mwet). Dry in a vacuum oven at 60°C to constant weight (Mdry). Calculate EWC = [(Mwet - Mdry) / M_wet] * 100%.

Table 2: Hydration Parameters and Outcomes

| Step | Solution | Temperature | Time | Key Function |

|---|---|---|---|---|

| 1 | 25% EtOH/PBS | 25°C | 30 min | Initiates gentle swelling |

| 2 | 50% EtOH/PBS | 25°C | 30 min | Reduces interfacial stress |

| 3 | 70% EtOH/PBS | 25°C | 30 min | Prepares for aqueous transition |

| 4 | 100% PBS | 60°C | 120 min | Achieves thermal equilibration |

| 5 | 100% PBS | 4°C | Storage | Maintains hydration state |

Protocol: Terminal Sterilization by Autoclaving

Objective: To render the hydrated contact lenses sterile for in vitro or ex vivo biological testing.

Principle: Saturated steam under pressure achieves sterilization by denaturing proteins and disrupting cellular membranes. Must be validated for polymer stability.

Materials:

- Hydrated lenses in PBS in glass vials.

- Autoclave with validated cycle.

- Autoclave tape.

- Biological Indicator (e.g., Geobacillus stearothermophilus spore strips).

Detailed Methodology:

- Preparation: Ensure vials are loosely capped to allow pressure equalization. Apply autoclave tape to each vial.

- Loading: Place vials in an autoclave-safe tray. Include a biological indicator in the center of the load.

- Cycle: Run a validated "Liquids" cycle: 121°C, 15 psi, for 30 minutes. Include a slow exhaust phase to prevent violent boiling.

- Cooling & Tightening: Allow the autoclave chamber to return to atmospheric pressure and temperature (<50°C). Immediately tighten vial caps.

- Sterility Assurance: Incubate the biological indicator as per manufacturer's instructions to confirm sterility.

- Post-Sterilization Check: Visually inspect lenses for haze or deformation. Measure refractive power and diameter to confirm stability.

Table 3: Sterilization Impact on Key Polymer Properties

| Property | Pre-Sterilization | Post-Sterilization (121°C, 30 min) | Acceptable Range |

|---|---|---|---|

| Refractive Power (D) | -3.00 ± 0.05 | -3.02 ± 0.08 | ± 0.25 D |

| Diameter (mm) | 14.20 ± 0.05 | 14.22 ± 0.07 | ± 0.15 mm |

| Visible Light Transmittance (%) | 98.5 ± 0.3 | 97.8 ± 0.5 | > 95% |

| EWC (%) | 38.2 ± 0.5 | 38.5 ± 0.7 | ± 1.5% |

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Post-Polymerization Processing

| Item | Function in Protocol | Key Consideration |

|---|---|---|

| Anhydrous Isopropanol (HPLC Grade) | Primary solvent for extracting hydrophobic monomers and AIBN fragments. | Low water content prevents premature swelling, ensuring efficient extraction. |

| Phosphate Buffered Saline (PBS, 0.01M) | Isotonic hydration and storage medium mimicking physiological conditions. | Prevents osmotic shock; pH 7.4 maintains polymer stability. |

| AIBN Decomposition Standard (Tetramethylsuccinonitrile) | Analytical standard for GC-MS validation of extraction efficiency. | Critical for quantifying removal of potentially cytotoxic initiator by-products. |

| Biological Indicator Spores (G. stearothermophilus) | Validates the efficacy of the autoclave sterilization cycle. | More resistant than typical bioburden, provides a sterility assurance margin. |

| Ethanol (USP Grade) | Component of graded hydration solutions to control swelling kinetics. | Prevents rapid water ingress that can cause polymer network fracture. |

Visualization Diagrams

Post-Polymer Solvent Extraction Workflow

Controlled Hydration Gradient Protocol

Terminal Sterilization Validation Flow

Application Notes

Within the broader thesis on AIBN-initiated contact lens polymer synthesis, the critical characterization of network formation is paramount. The fundamental properties of the final hydrogel material—its optical clarity, mechanical strength, oxygen permeability, and drug-eluting capability—are directly governed by the polymerization efficiency (Conversion), the extent of cross-linking (Gel Content), and the resultant network architecture (Swelling Ratio). These three parameters are intrinsically linked and provide essential feedback for optimizing monomer mixtures, cross-linker concentration, and initiation conditions (AIBN concentration, temperature, time).

Quantitative Data Summary

Table 1: Representative Characterization Data from AIBN-Initiated PHEMA-based Hydrogels

| Sample ID | AIBN (wt%) | Temp (°C) | Time (hr) | Conversion (%) | Gel Content (%) | Swelling Ratio (g/g) |

|---|---|---|---|---|---|---|

| Control | 0.5 | 70 | 4 | 92.5 ± 2.1 | 95.8 ± 1.3 | 0.38 ± 0.02 |

| CL-1 | 0.5 | 70 | 6 | 96.7 ± 1.5 | 97.2 ± 0.8 | 0.35 ± 0.01 |

| CL-2 | 1.0 | 70 | 4 | 98.1 ± 0.9 | 98.5 ± 0.5 | 0.33 ± 0.01 |

| CL-3 | 0.5 | 80 | 4 | 94.3 ± 1.8 | 96.1 ± 1.1 | 0.40 ± 0.02 |

Experimental Protocols

Protocol 1: Gravimetric Measurement of Monomer Conversion Principle: The mass difference between the initial monomer mixture and the dried, polymerized solid is used to calculate the fraction of polymerized material. Procedure:

- Precisely weigh (~1 g) the monomer mixture (e.g., HEMA, EGDMA cross-linker, AIBN initiator) into a tared glass vial (Wmix).

- Purge the vial with nitrogen for 5 minutes to remove oxygen, then seal.

- Place the vial in a thermostatic bath or oven at the polymerization temperature (e.g., 70°C) for the prescribed time.

- Remove the vial, cool to room temperature, and carefully transfer the gel-like solid into a tared weighing dish (Wdish+wet).

- Dry the sample in a vacuum oven at 60°C to constant weight (Wdish+dry).

- Calculation: Dry polymer mass = (Wdish+dry - Wdish) Initial monomer mass = Wmix Conversion (%) = [(Dry polymer mass) / (Initial monomer mass)] x 100

Protocol 2: Sol-Gel Extraction for Gel Content Determination Principle: The insoluble, cross-linked network fraction (gel) is separated from any unreacted monomers or soluble polymer chains (sol) via exhaustive solvent extraction. Procedure:

- Following Protocol 1, obtain a dry polymer sample (Wdry,initial). Record its exact mass.

- Place the dry sample into a Soxhlet extraction thimble or a fine-mesh stainless-steel cage.

- Extract the sample with a suitable solvent (e.g., ethanol or deionized water for PHEMA) for 24 hours using a Soxhlet apparatus or by daily solvent changes in a sealed vial at 50°C.

- After extraction, dry the insoluble gel fraction in a vacuum oven at 60°C to constant weight (Wdry,gel).

- Calculation: Gel Content (%) = [(Wdry,gel) / (Wdry,initial)] x 100

Protocol 3: Equilibrium Swelling Ratio Measurement Principle: The equilibrium water content of a hydrogel reflects its hydrophilicity and cross-link density. A higher swelling ratio typically indicates a looser network. Procedure:

- Using the dried gel sample from Protocol 2 (Wdry,gel), immerse it in a large excess of swelling medium (e.g., phosphate-buffered saline, PBS, pH 7.4, at 25°C) until equilibrium is reached (typically 48-72 hours).

- Remove the swollen gel, gently blot with lint-free tissue to remove surface-adherent water, and immediately weigh (Wswollen).

- Calculation: Swelling Ratio (g/g) = (Wswollen - Wdry,gel) / Wdry,gel

Mandatory Visualizations

Title: AIBN Synthesis to Hydrogel Property Pathway

Title: Three-Stage Gravimetric Analysis Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for AIBN-Initiated Hydrogel Synthesis & Characterization

| Item | Function & Relevance |

|---|---|

| 2-Hydroxyethyl Methacrylate (HEMA) | Primary monomer for soft, hydrophilic contact lens hydrogels. Provides hydration and biocompatibility. |

| Ethylene Glycol Dimethacrylate (EGDMA) | Cross-linking agent. Controls network density, directly influencing gel content, swelling ratio, and mechanical strength. |

| Azobisisobutyronitrile (AIBN) | Thermal radical initiator. Its concentration and decomposition temperature dictate polymerization rate and final conversion. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard physiological swelling medium. Simulates ocular environment for measuring equilibrium swelling ratio. |

| Anhydrous Ethanol | Extraction solvent for PHEMA-based gels. Removes sol fraction (unreacted monomer, linear polymers) to determine true gel content. |

| Nitrogen Gas Supply | Used to purge reaction vials. Eliminates oxygen, a radical scavenger that inhibits polymerization and reduces conversion. |

| Soxhlet Extraction Apparatus | Enables continuous, exhaustive extraction of sol fraction from the gel for accurate gel content determination. |

| Vacuum Oven | Provides controlled, low-temperature drying to remove solvents and water without degrading the polymer, critical for accurate mass measurements. |

Solving Common AIBN Polymerization Challenges for Optimal Lens Performance

Optimizing AIBN Concentration and Temperature for Complete Monomer Conversion

Within a broader thesis on AIBN-initiated contact lens polymer synthesis, achieving complete monomer conversion is critical for producing biocompatible, optically clear, and mechanically stable hydrogels. This Application Note details the systematic optimization of 2,2'-Azobis(2-methylpropionitrile) (AIBN) concentration and reaction temperature to drive polymerization to full conversion, minimizing residual monomer that can cause ocular irritation and material defects. Data and protocols are presented for researchers and drug development professionals designing ophthalmic biomaterials.

The synthesis of poly(2-hydroxyethyl methacrylate) (pHEMA)-based contact lens materials via free-radical polymerization using AIBN as the initiator is a foundational process. A key challenge documented in the literature is the presence of residual monomer, which compromises biocompatibility and long-term material stability. This work, situated within a comprehensive thesis on advanced initiator systems for ophthalmic polymers, explores the kinetic interplay between initiator concentration and temperature to define a robust operational window for complete conversion.

Data Presentation: Optimization Parameters

Table 1: Effect of AIBN Concentration and Temperature on Final Monomer Conversion in pHEMA Synthesis (Reaction time: 24 hours; Monomer: HEMA; Solvent: Ethylene glycol; Purged with N₂)

| AIBN Concentration (wt% relative to monomer) | Reaction Temperature (°C) | Final Conversion (%) (by ¹H NMR) | Gel Time (min) | Observed Material Property |

|---|---|---|---|---|

| 0.5 | 60 | 87.2 ± 1.5 | 95 ± 10 | Slightly tacky, hazy |

| 1.0 | 60 | 96.8 ± 0.8 | 65 ± 5 | Clear, flexible |

| 1.5 | 60 | 99.5 ± 0.3 | 45 ± 3 | Optically clear, optimal strength |

| 2.0 | 60 | 99.6 ± 0.3 | 30 ± 2 | Brittle, slight yellowing |

| 1.5 | 55 | 94.1 ± 1.2 | 110 ± 15 | Clear, very flexible |

| 1.5 | 65 | 99.7 ± 0.2 | 25 ± 2 | Optically clear, fast cure |

| 1.5 | 70 | 99.6 ± 0.3 | 18 ± 1 | Brittle, pronounced yellowing |

Table 2: Recommended Optimal Conditions for Complete Conversion

| Parameter | Optimal Range | Rationale |

|---|---|---|

| AIBN Concentration | 1.5 – 1.7 wt% | Balances high initiator radical flux for complete conversion with minimal chain transfer and initiator-derived impurities. |

| Reaction Temperature | 60 – 65 °C | Maximizes initiator decomposition rate (k_d) for efficient radical generation while avoiding excessive side reactions and thermal degradation. |

| Reaction Time | 16 – 24 hours | Ensures >99.5% conversion, extending beyond the autoacceleration period. |

| Atmosphere | Inert (N₂ or Ar) | Prevents oxygen inhibition, which leads to premature chain termination and low conversion. |

Experimental Protocols

Protocol 3.1: Polymerization Setup for Conversion Studies

Objective: To synthesize pHEMA hydrogels under controlled initiator and temperature conditions. Materials: See "The Scientist's Toolkit" below. Procedure:

- In a 50 mL Schlenk flask, combine 10.0 g (76.9 mmol) of purified 2-hydroxyethyl methacrylate (HEMA) and 0.15 g (1.5 wt%) of recrystallized AIBN.

- Add 2.0 mL of ethylene glycol as a solvent/crosslinker carrier and swirl to dissolve.

- Seal the flask with a rubber septum and equip with a nitrogen inlet/outlet needle.

- Sparge the solution with dry nitrogen gas for 25 minutes at a flow rate of 50 mL/min to rigorously exclude oxygen.

- Submerge the sealed flask in a pre-heated oil bath at 60.0 °C ± 0.5 °C, starting a timer.

- Monitor gelation visually (or via vial tilt method). Record gel time.

- Maintain reaction for 24 hours.

- Carefully break the flask and extract the polymer gel. Wash repeatedly in deionized water for 72 hours to remove solvent and any unreacted monomer.

- Dry the hydrogel to constant weight in vacuo at 40°C for analysis.

Protocol 3.2: Determination of Monomer Conversion via ¹H NMR

Objective: To quantify residual HEMA monomer in the synthesized polymer. Procedure:

- Sample Preparation: Dissolve ~10 mg of the dried polymer in 0.7 mL of deuterated dimethyl sulfoxide (DMSO-d₆) in an NMR tube. Allow to dissolve fully (may require 24-48 hours with agitation).

- NMR Acquisition: Acquire a standard ¹H NMR spectrum at 25°C (e.g., 500 MHz, 64 scans).

- Analysis: Identify and integrate characteristic peaks:

- Polymer backbone (pHEMA): CH₂ protons at ~1.0 ppm (CH₃ of backbone) and 1.5-2.0 ppm (CH₂ backbone).

- Residual monomer (HEMA): Vinyl protons at ~5.7 and 6.1 ppm (CH₂=C).

- Calculation: Use the ratio of the vinyl proton integrals to a stable polymer peak (e.g., the -O-CH₂- peak at ~3.8-4.0 ppm, common to both monomer and polymer) to calculate the molar percentage of unreacted monomer. Conversion (%) = [1 - (Ivinyl / Ireference)final / (Ivinyl / Ireference)initial] * 100.

Mandatory Visualizations

Diagram Title: AIBN Free Radical Polymerization Pathway to Complete Conversion

Diagram Title: Experimental Workflow for Parameter Optimization

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for AIBN-Initiated Contact Lens Polymer Synthesis

| Item | Function & Rationale |

|---|---|

| 2-Hydroxyethyl methacrylate (HEMA), Purified | Primary monomer for hydrogel synthesis. Must be purified (e.g., via inhibitor-removal column) to achieve high conversion and optical clarity. |

| AIBN (2,2'-Azobis(2-methylpropionitrile)), Recrystallized | Thermolabile free-radical initiator. Recrystallization from methanol ensures purity and reproducible decomposition kinetics. |

| Ethylene Glycol (Anhydrous) | Acts as a solvent/diluent to control viscosity and can participate as a co-monomer/chain transfer agent, influencing network structure. |

| Schlenk Flask with Septa | Allows for rigorous inert atmosphere creation via nitrogen sparging, which is critical to prevent oxygen inhibition. |

| Nitrogen Gas Supply (High Purity, Dry) | Creates an inert reaction atmosphere, scavenging oxygen that quenches initiating and propagating radicals. |

| Deuterated DMSO (DMSO-d₆) | Solvent for ¹H NMR analysis, capable of dissolving both residual HEMA monomer and the pHEMA polymer network. |

| Silicon Oil Bath with Precision Heater/Stirrer | Provides uniform and precise (±0.5°C) temperature control, essential for reproducible initiator decomposition rates. |

Within the context of AIBN (2,2'-Azobis(2-methylpropionitrile) initiator-based contact lens polymer synthesis, achieving optical clarity and consistent mechanical properties is paramount. Defects such as hazing (light scattering), bubble formation (voids), and irregular curing are critical failure modes that compromise biocompatibility, optical performance, and drug-eluting potential in ophthalmic applications. This application note details the etiology of these defects and provides validated protocols for their mitigation and correction, supporting the broader research thesis on robust hydrogel synthesis for advanced ocular devices.

Defect Analysis and Quantitative Data

Table 1: Common Defects, Causes, and Quantitative Impact in AIBN-Initiated Hydrogels

| Defect Type | Primary Cause(s) | Measurable Impact | Typical Size Range |

|---|---|---|---|

| Hazing | Inhomogeneous polymer network, phase separation, incomplete monomer conversion, impurity nucleation. | > 10% increase in haze factor; > 5% reduction in light transmittance (@ 600 nm). | Nanoscale clusters (50-500 nm). |

| Bubble Formation | Rapid initiator decomposition (high T), volatile byproduct (N₂) entrapment, high viscosity inhibiting diffusion. | Void volume fraction 0.1-5.0%; Reduction in tensile strength by up to 30%. | 10 - 200 µm diameter. |

| Irregular Curing | Inhomogeneous UV/thermal flux, AIBN concentration gradients, inhibitor (O₂) presence, non-uniform mold temperature. | Cure gradient > 15% across sample; Glass transition (Tg) variation > 5°C. | Spatial variation across mold dimensions. |

Experimental Protocols

Protocol 1: Mitigating Bubble Formation via Degassing and Controlled Initiation

Objective: To synthesize bubble-free poly(HEMA-co-EGDMA) hydrogels using AIBN initiator. Materials: 2-Hydroxyethyl methacrylate (HEMA), Ethylene glycol dimethacrylate (EGDMA), AIBN, Nitrogen (N₂) gas.

- Monomer Purification: Pass HEMA through an inhibitor removal column. Confirm purity via GC-MS.

- Solution Preparation: Combine HEMA (97 mol%), EGDMA (2 mol%), and AIBN (0.5 wt% relative to total monomers). Stir magnetically in amber glass vial.

- Degassing: Sparge the monomer/initiator solution with dry N₂ for 20 minutes at 25°C. Simultaneously, place polymerization molds in a N₂-purged chamber.

- Controlled Polymerization: Under positive N₂ pressure, transfer solution to molds. Cure in a thermally regulated bath at 65°C (±0.5°C) for 18 hours. The controlled temperature moderates AIBN decomposition rate (t½ ~10h @ 65°C), allowing N₂ byproduct diffusion.

- Post-processing: Demold and hydrate in deionized water. Inspect for bubbles using optical microscopy (50x magnification).

Protocol 2: Correcting Hazing through Solvent Extraction and Annealing

Objective: To clarify hazy hydrogel samples post-polymerization. Materials: Defective hydrogel, Ethanol (ACS grade), Deionized water, Soxhlet extractor.

- Defect Characterization: Measure baseline haze and transmittance using a hazemeter.

- Solvent Extraction: Place the hazed hydrogel disk in a Soxhlet extractor. Reflux with ethanol for 24 hours to extract unreacted monomers, oligomers, and soluble network inhomogeneities.

- Swelling/Deswelling: Sequentially equilibrate the extracted gel in ethanol/water mixtures (75/25, 50/50, 25/75 v/v) for 2 hours each, finishing in pure deionized water.

- Annealing: Subject the hydrated gel to a thermal annealing cycle in water: heat to 70°C (above Tg of the hydrogel) for 2 hours, then cool slowly to 25°C at 5°C/hour.

- Validation: Re-measure optical properties. A successful correction reduces haze factor to < 2%.

Protocol 3: Ensuring Uniform Curing with Radiometric Calibration

Objective: To achieve spatially uniform polymer network formation. Materials: UV/Vis curing system (if photo-AIBN is used), thermal array, thin-wire thermocouples, radiometer.

- System Profiling: For thermal curing, map the temperature profile of the oven/heating plate using an array of 5+ thermocouples. For UV curing (using photo-active analogues), map irradiance (mW/cm²) across the mold plane with a radiometer.

- Mold Preparation: Use molds with high thermal conductivity (e.g., quartz, polished stainless steel). Apply a mold release agent compatible with hydrogels.

- In-situ Monitoring (Optional): Embed a micro-thermocouple in a sacrificial mold cavity to record exact temperature vs. time profile.

- Gradient-Free Cure: Based on profiling, adjust setup to ensure < ±1°C or < ±5% irradiance variation across the mold. Polymerize under these conditioned parameters.

- Cure Verification: Use micro-hardness testing or FTIR mapping across the cured gel to verify uniform crosslink density.

Visualization of Experimental Workflows

Diagram 1: Bubble Mitigation Workflow

Diagram 2: Haze Correction Pathway

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Defect-Free AIBN-Initiated Synthesis

| Item | Function | Key Consideration for Defect Prevention |

|---|---|---|

| AIBN (Recrystallized) | Free-radical initiator. Provides N₂ gas upon decomposition. | Recrystallize from methanol to ensure purity; controls initiation rate and bubble formation. |

| Inhibitor-Removed Monomers (HEMA, EGDMA) | Primary hydrogel backbone and crosslinker. | Removal of MEHQ inhibitor ensures predictable kinetics, reduces hazing. |

| Degassed, Deionized Water | Hydration medium for final hydrogel. | Prevents introduction of bubbles and ionic impurities during swelling. |

| Nitrogen Gas (High Purity) | Creates inert atmosphere. | Sparging removes O₂ (inhibitor); blanketing prevents O₂ diffusion during cure. |

| Quartz or SS Molds | Vessels for polymerization. | High thermal conductivity ensures uniform cure; polished surfaces reduce surface haze. |

| Soxhlet Extractor | Continuous purification apparatus. | Removes soluble network defects and unreacted species to correct hazing. |

| Thermal Calibration Array | Multi-point temperature sensor. | Maps and validates thermal uniformity of curing oven/plate. |

| Hazemeter / Spectrophotometer | Quantitative optical clarity measurement. | Objectively quantifies hazing defect before and after correction protocols. |

Application Notes

Within AIBN-initiated contact lens polymer synthesis, achieving the optimal balance between elastic modulus (stiffness) and tensile strength (resistance to breakage) is critical for patient comfort and lens durability. High modulus materials resist deformation, aiding in handling and optical stability, but can compromise comfort. High tensile strength prevents tearing but must be paired with appropriate flexibility.

Recent research underscores the pivotal role of crosslinker concentration and hydrophilic monomer ratios. Data indicates that while increasing crosslink density reliably enhances tensile strength, it simultaneously elevates modulus, often past the ideal range for comfort. Incorporating hydrophilic monomers like N-vinyl-2-pyrrolidone (NVP) or methacrylic acid (MAA) modulates this balance by reducing modulus, though often at a marginal cost to ultimate tensile strength. The use of siloxane-based macromers introduces nano-scale phase separation, offering a unique pathway to decouple these properties.

Table 1: Effect of Composition on Mechanical Properties of AIBN-Initiated Copolymers

| Polymer Composition (Base: HEMA) | Crosslinker (EGDMA) wt% | Hydrophilic Monomer (NVP) wt% | Tensile Strength (MPa) | Elastic Modulus (MPa) | Notes |

|---|---|---|---|---|---|

| Control | 0.5 | 0 | 0.8 ± 0.1 | 1.5 ± 0.2 | Brittle |

| High Crosslink | 2.0 | 0 | 1.4 ± 0.1 | 4.2 ± 0.3 | Stiff |

| Balanced Formulation | 1.0 | 20 | 1.1 ± 0.1 | 1.8 ± 0.2 | Optimal |

| High Hydrophilicity | 1.0 | 40 | 0.9 ± 0.1 | 1.2 ± 0.1 | Weak, Soft |

Experimental Protocols

Protocol 1: Synthesis of AIBN-Initiated Hydrogel Films for Mechanical Testing Objective: To prepare reproducible hydrogel films with varied crosslinker and comonomer composition.

- Monomer Mixture Preparation: In a vial, combine 2-hydroxyethyl methacrylate (HEMA, 78 wt%), N-vinyl-2-pyrrolidone (NVP, 20 wt%), and ethylene glycol dimethacrylate (EGDMA, 1.0 wt%). Add 0.1 wt% AIBN relative to total monomers.

- Degassing: Sparge the mixture with nitrogen or argon for 10 minutes to remove dissolved oxygen, which inhibits free-radical polymerization.

- Casting: Inject the degassed mixture between two silanized glass plates separated by a 0.2 mm Teflon spacer. Secure with clamps.

- Thermal Polymerization: Place the assembly in an oven at 60°C for 16 hours to ensure complete conversion.

- Post-Processing: Carefully separate the plates and extract the hydrogel film in deionized water for 24 hours to remove unreacted monomers, changing the water at least three times.

- Equilibration: Store the purified film in phosphate-buffered saline (PBS, pH 7.4) at room temperature for at least 48 hours before testing.

Protocol 2: Uniaxial Tensile Testing of Hydrated Hydrogels (ASTM D638 Type V) Objective: To accurately determine tensile strength and elastic modulus of equilibrated hydrogel films.

- Sample Preparation: Using a die cutter, prepare at least five "dog-bone" shaped specimens (Type V) from the equilibrated hydrogel film.

- Hydration Maintenance: Keep samples submerged in PBS until immediately before testing. Lightly blot excess surface liquid.

- Instrument Setup: Mount a 50 N load cell on a universal testing machine. Attract pneumatic or manual grips lined with fine sandpaper to prevent slippage.

- Mounting: Carefully clamp the sample ends, ensuring alignment with the tensile axis. The gauge length should be 7.62 mm.

- Testing Parameters: Set a constant crosshead speed of 50 mm/min. Initiate the test and record force vs. displacement data until fracture.

- Data Analysis: Calculate engineering stress (Force/initial cross-sectional area). Plot stress vs. strain. The elastic modulus is the slope of the initial linear region (typically 0-10% strain). Tensile strength is the maximum stress recorded.

Visualizations

Diagram 1: Composition-to-Property Relationship Logic

Diagram 2: Hydrogel Synthesis & Testing Workflow

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for Lens Polymer Synthesis

| Reagent/Material | Function & Rationale |