ATP Detection in Biomaterial Testing: The Definitive Guide to Accurate Cell Viability Assessment

This comprehensive guide explores the application of ATP (adenosine triphosphate) detection assays for assessing cell viability on biomaterials.

ATP Detection in Biomaterial Testing: The Definitive Guide to Accurate Cell Viability Assessment

Abstract

This comprehensive guide explores the application of ATP (adenosine triphosphate) detection assays for assessing cell viability on biomaterials. Targeted at researchers and development professionals, it covers the foundational principles of ATP as a viability marker, detailed methodological protocols for 2D and 3D scaffolds, common troubleshooting and optimization strategies for material-specific challenges, and a comparative analysis with other viability assays. The article provides actionable insights to enhance the accuracy, reliability, and translational relevance of cell-material interaction studies in tissue engineering and regenerative medicine.

Why ATP is the Gold Standard for Biomaterial Cell Viability: Principles and Core Concepts

ATP as a Universal Marker of Metabolic Activity and Cell Health

Within biomaterial cell viability research, quantifying cellular health and metabolic activity is paramount. Adenosine triphosphate (ATP) serves as a universal marker, as its concentration is directly proportional to the number of metabolically active cells. This application note, framed within a broader thesis on optimizing ATP detection for novel biomaterial testing, provides current protocols and data for researchers in drug development and biomaterial science. Accurate ATP quantification enables high-throughput assessment of cytotoxicity, biocompatibility, and treatment efficacy on 2D and 3D biomaterial scaffolds.

Core Principles and Current Data

ATP detection assays are primarily based on the firefly luciferase reaction: Luciferase catalyzes the oxidation of D-luciferin in the presence of ATP and Mg²⁺, producing light proportional to ATP concentration. Key advancements include stabilized enzyme formulations, enhanced sensitivity (detection down to single cells), and compatibility with 3D culture systems.

Table 1: Comparative Performance of Commercially Available ATP Detection Assay Kits

| Kit Name (Manufacturer) | Sensitivity (Moles ATP) | Linear Range | Compatible Sample Types | Key Feature for Biomaterials |

|---|---|---|---|---|

| CellTiter-Glo 3D (Promega) | <1 zeptomole | 6 orders of magnitude | Monolayers, 3D spheroids, scaffolds | Lytic reagent penetrates microtissues |

| ViaLight Plus (Lonza) | 10 femtomoles | 4 orders of magnitude | Adherent cells, suspension cells | Designed for cytotoxicity testing |

| ATP Lite (PerkinElmer) | <0.1 picomole | 5 orders of magnitude | High-throughput screening | High signal stability (>5 hrs) |

| RealTime-Glo MT (Promega) | N/A (Real-time) | N/A | Non-lytic, long-term monitoring | Non-lytic, reversible measurement |

Table 2: ATP Content in Common Cell Lines (Representative Values)

| Cell Line | Typical ATP per Cell (picomoles) | Notes |

|---|---|---|

| HEK293 | 0.5 - 1.5 | High metabolic rate |

| HepG2 | 1.0 - 2.0 | Liver-derived, high metabolism |

| Primary Human Fibroblasts | 0.2 - 0.8 | Donor and passage dependent |

| hMSCs on PLLA Scaffold | 0.1 - 0.5* | Varies with scaffold porosity and age |

*Value typically lower than monolayer due to assay extraction efficiency from 3D matrix.

Detailed Experimental Protocols

Protocol 3.1: Standard ATP Assay for 2D Cultures on Biomaterial Coatings

Application: Testing cytotoxicity of coating materials or drug treatments. Materials: White-walled 96-well plate, test biomaterial-coated plate, ATP detection reagent (e.g., CellTiter-Glo 2.0), plate shaker, luminescence plate reader. Procedure:

- Cell Seeding & Treatment: Seed cells onto biomaterial-coated plates at optimal density. Apply experimental treatments (e.g., drug compounds, nanomaterials) for desired duration.

- Equilibration: Equilibrate plate and ATP detection reagent to room temperature for 30 minutes.

- Reagent Addition: Add a volume of detection reagent equal to the culture medium volume in each well.

- Lysis & Signal Generation: Place plate on orbital shaker for 2 minutes to induce cell lysis, then incubate at room temperature for 10 minutes to stabilize luminescent signal.

- Measurement: Record luminescence using an integration time of 0.5-1 second per well.

- Analysis: Normalize raw RLU (Relative Light Units) of treated wells to untreated controls (set as 100% viability).

Protocol 3.2: ATP Assay for 3D Biomaterial Scaffolds or Hydrogels

Application: Assessing viability within three-dimensional constructs (critical for tissue engineering). Materials: 3D cell-laden construct, ATP detection reagent for 3D cultures (e.g., CellTiter-Glo 3D), opaque-walled multi-well plate, plate shaker with orbital capability. Procedure:

- Construct Preparation: Culture cells within hydrogel or porous scaffold for desired period.

- Transfer: Gently transfer each 3D construct to a fresh well of an opaque-walled plate.

- Reagent Addition: Add ATP detection reagent in a 1:1 volume ratio to the construct volume (ensure complete immersion).

- Lysis & Penetration: Shake plate vigorously (700 rpm orbital) for 5 minutes to lyse cells and ensure reagent penetration into the matrix.

- Incubation: Incubate plate at room temperature for 25 minutes to stabilize signal.

- Measurement & Analysis: Record luminescence. Include acellular scaffold + reagent controls for background subtraction. Use a standard curve of known ATP concentrations for absolute quantification if required.

Signaling and Metabolic Pathways Involving ATP

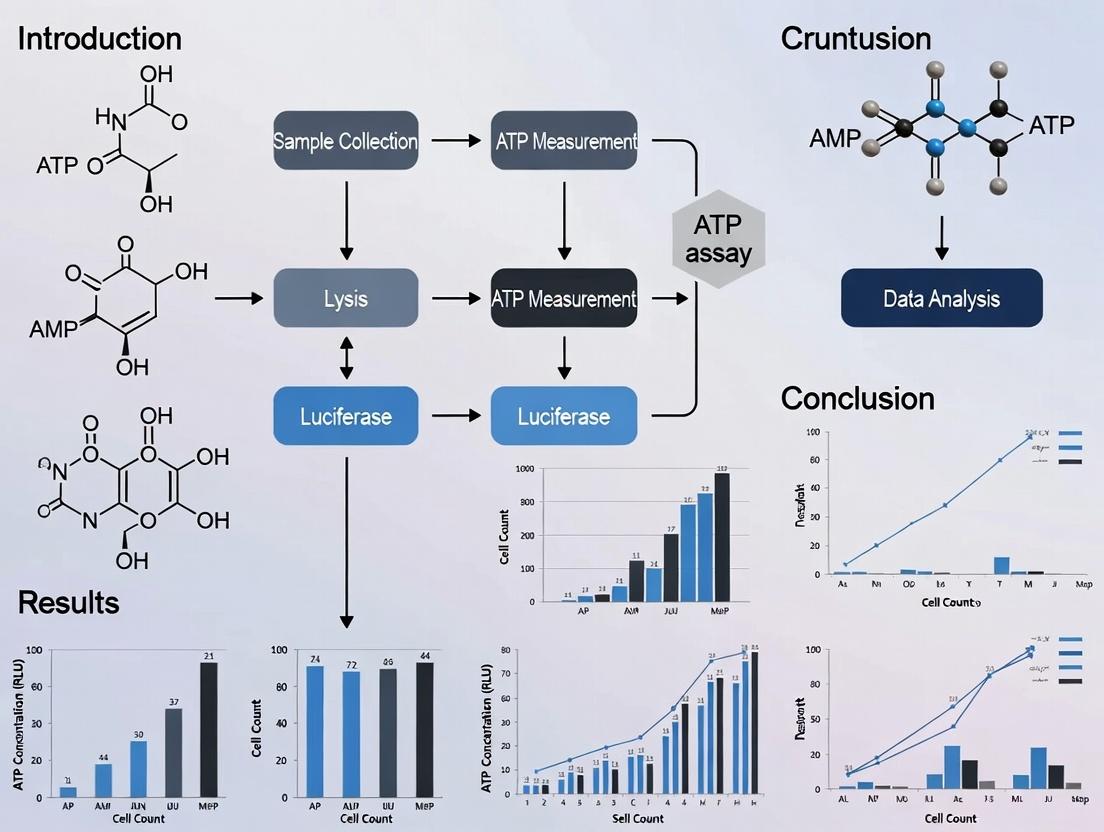

Diagram 1: ATP in Central Metabolism & Bioenergetics

Experimental Workflow for Biomaterial Testing

Diagram 2: ATP Assay Workflow for Biomaterials

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for ATP Detection Assays

| Item | Function & Importance |

|---|---|

| Firefly Luciferase Enzyme (Recombinant, Stabilized) | Core enzyme for bioluminescent reaction. Stabilized forms offer extended half-life and robust performance. |

| D-Luciferin Substrate | Light-emitting substrate oxidized in the presence of ATP, Mg²⁺, and luciferase. Purity is critical for low background. |

| Cell Lysis Reagent with Detergent | Lyse cell membranes to release intracellular ATP. For 3D assays, must penetrate extracellular matrix. |

| ATP Standard (Lyophilized) | Pure ATP for generating a standard curve, enabling absolute quantification of cellular ATP. |

| Reaction Buffer (with Mg²⁺ and Co-factors) | Provides optimal pH and essential divalent cations (Mg²⁺) for maximal luciferase activity. |

| Sterile, White/Opaque-Walled Multiwell Plates | Prevent cross-talk of luminescent signal between wells. Essential for accurate high-throughput reading. |

| Recombinant Apyrase (ATP Eliminating Enzyme) | Negative control to confirm signal specificity by degrading ATP in control samples. |

| Biomaterial-Specific Positive Control (e.g., Triton X-100) | A potent cytolytic agent to establish 0% viability baseline for a given biomaterial system. |

Within the broader thesis on optimizing biomaterial cell viability assessment, establishing a robust, quantitative correlation between intracellular ATP concentration and viable cell number is paramount. ATP serves as the universal energy currency in all metabolically active cells, and its rapid depletion upon loss of viability makes it a superior marker compared to membrane integrity assays. This application note details the protocols, validation data, and practical considerations for employing ATP detection assays in biomaterial research, from 3D scaffold cultures to monolayer screenings on novel polymer surfaces.

The following tables summarize empirical data from recent studies validating the ATP-viable cell correlation across various cell types and assay formats.

Table 1: Correlation Coefficients (R²) for ATP vs. Viable Cell Number

| Cell Line | Assay Format | Biomaterial Context | Linear Range (Cells) | R² Value | Reference Year |

|---|---|---|---|---|---|

| Human Mesenchymal Stem Cells (hMSCs) | 2D Monolayer | Tissue Culture Plastic | 100 - 50,000 | 0.998 | 2023 |

| MC3T3-E1 Osteoblasts | 3D Culture | PCL-TCP Scaffold | 500 - 100,000 | 0.992 | 2024 |

| HepG2 Hepatocytes | 2D Monolayer | Functionalized Silk Film | 200 - 25,000 | 0.995 | 2023 |

| Primary Human Dermal Fibroblasts | 3D Hydrogel | Alginate-Collagen Blend | 1,000 - 100,000 | 0.987 | 2024 |

Table 2: ATP Assay Sensitivity Comparison

| Commercial ATP Assay Kit | Detection Principle | Luminescence Signal Half-Life | Sensitivity (Moles ATP) | Ideal for 3D Biomaterials? |

|---|---|---|---|---|

| Kit A (CellTiter-Glo 3D) | Luciferin/Luciferase, Thermostable | > 3 hours | < 1 x 10^-12 | Yes (Enhanced lysing) |

| Kit B (ViaLight Plus) | Luciferin/Luciferase + Nucleotide Releasing Agent | ~30 minutes | < 5 x 10^-13 | Limited (2D optimized) |

| Kit C (ATPite) | Recombinant Luciferase, Single-step | ~1 hour | < 1 x 10^-12 | Yes (Designed for scaffolds) |

Detailed Experimental Protocols

Protocol 1: ATP-based Viability Assessment for Cells on 2D Biomaterial Coatings

Objective: To quantify the number of viable cells adhering to a novel 2D biomaterial coating (e.g., polymer film, deposited peptide layer).

Materials:

- Cells seeded on coated plates (24-well or 96-well format).

- ATP detection kit (e.g., CellTiter-Glo 2.0).

- Opaque-walled multiwell assay plates.

- Microplate shaker.

- Luminometer or plate reader with luminescence detection.

Procedure:

- Equilibration: Remove cell culture plates from incubator. Equilibrate to room temperature (RT) for 30 minutes to stabilize the luminescent signal.

- Reagent Preparation: Thaw and equilibrate the lyophilized substrate/buffer to RT. Reconstitute and mix to form the homogeneous GLO Reagent.

- Reagent Addition: Add a volume of GLO Reagent equal to the volume of culture medium present in each well (e.g., add 100 µL to 100 µL of medium in a 96-well plate).

- Lysing & Signal Generation: Place plates on an orbital shaker for 2 minutes at 500 rpm to induce cell lysis, followed by a 10-minute incubation at RT to stabilize the luminescent signal.

- Measurement: Transfer 100-150 µL of the lysate to an opaque-walled plate if necessary. Record luminescence (RLU) using an integration time of 0.5-1 second per well.

- Analysis: Generate a standard curve using known cell numbers plated on a standard tissue culture surface. Plot RLU vs. cell number to establish the linear correlation. Apply the equation to unknown samples.

Protocol 2: ATP Quantification for 3D Biomaterial Constructs (e.g., Hydrogels, Porous Scaffolds)

Objective: To measure viable cell number within three-dimensional biomaterial constructs where diffusion and lysis efficiency are critical.

Materials:

- 3D cell-laden constructs (in 24- or 96-well plates).

- ATP detection kit optimized for 3D matrices (e.g., CellTiter-Glo 3D).

- Sterile forceps or wide-bore tips.

- Opaque-walled assay plates.

- Luminometer.

Procedure:

- Construct Transfer (Optional): For bulky scaffolds, carefully transfer each construct to a new well of an opaque assay plate using sterile forceps to avoid cross-talk.

- Reagent Addition: Add a volume of CellTiter-Glo 3D Reagent equal to the volume of culture medium + construct. Typically, 100-200 µL for a 96-well format.

- Orbital Shaking: Shake plates vigorously (700-900 rpm) on an orbital shaker for 5-10 minutes. This step is crucial to disrupt the 3D matrix and ensure complete cell lysis and reagent penetration.

- Incubation: Incubate at RT for 25 minutes to stabilize the signal. The extended incubation compensates for the larger diffusion distances.

- Measurement & Analysis: Record luminescence. For analysis, generate a standard curve using cells seeded in a representative 3D construct at known densities, processed identically. Correlation in 3D is matrix-dependent and must be empirically validated.

Visualization: Pathways & Workflows

Diagram Title: ATP Assay Correlation Logic (87 chars)

Diagram Title: ATP Assay Workflow for 2D/3D Biomaterials (100 chars)

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item/Reagent | Function in ATP Assay | Key Consideration for Biomaterials |

|---|---|---|

| Recombinant Luciferase Enzyme | Catalyzes the light-producing reaction. Requires ATP as a co-substrate. | Thermostable variants (e.g., from Photinus pyralis) are essential for consistent signal in 3D assays with longer processing times. |

| D-Luciferin (Substrate) | Photon-producing luciferase substrate. Reacts with ATP, Mg²⁺, and O₂. | Must be combined with cell lysis agents. Purity affects background luminescence. |

| Cell Lysis Detergent/Agent | Disrupts cell membranes to release intracellular ATP. | For 3D scaffolds/hydrogels, a stronger, penetrating detergent blend is required (e.g., included in "3D" optimized kits). |

| ATP Standards (for Calibration) | Used to generate a standard curve correlating RLU to ATP moles. | Critical for absolute quantification. Must be prepared fresh to avoid degradation. |

| Nucleotide Releasing Buffer (Proprietary) | Typically a blend of detergent, buffer, and stabilizers to optimize lysis and inhibit ATPases. | The core of kit performance. Optimized buffers differ for 2D vs. 3D applications. |

| Signal Stabilizing Agents (e.g., Enhancers) | Prolongs half-life of luminescent signal from minutes to hours. | Allows batch processing of multiple plates, crucial for high-throughput screening of biomaterial libraries. |

| Opaque-Walled Multiwell Plates | Prevents signal cross-talk between adjacent wells during luminescence reading. | Essential for accuracy. White plates maximize signal reflection; black plates minimize background. |

Key Advantages Over Other Viability Assays for Biomaterial Applications

In the context of a thesis on ATP detection for biomaterial cell viability, understanding the comparative advantages of the bioluminescent ATP assay is critical. It is the gold standard for quantifying metabolically active cells on biomaterial scaffolds due to its sensitivity, speed, and linearity.

Comparative Analysis of Viability Assays

Table 1: Quantitative Comparison of Key Viability Assays for Biomaterial Testing

| Assay Type | Primary Measurement | Detection Limit (Cells/Well) | Assay Time Post-Lysis | Linearity Range | Key Interference in Biomaterials |

|---|---|---|---|---|---|

| Bioluminescent ATP | ATP concentration (Metabolic activity) | 1 - 10 | < 30 minutes | Up to 7 logs | Low. Luciferase reaction is specific. |

| Resazurin (AlamarBlue) | Reducing potential (Metabolism) | 100 - 1,000 | 1 - 4 hours | 3 - 4 logs | High. Material redox activity causes false positives. |

| MTT/XTT | Mitochondrial reductase activity | 500 - 5,000 | 1 - 4 hours | 2 - 3 logs | Very High. Material absorption/scattering affects OD. |

| Calcein-AM (Live Stain) | Esterase activity (Membrane integrity) | 50 - 100 | 30 - 60 mins (live imaging) | 2 - 3 logs | Medium. Non-specific esterase activity or quenching. |

| LDH Release | Membrane integrity (Cytotoxicity) | 500 - 1,000 | 30 - 60 minutes | 2 - 3 logs | Medium. Serum in media contains background LDH. |

Table 2: Performance in Common Biomaterial Scenarios

| Scenario | Optimal Assay | Rationale | ATP Assay Advantage |

|---|---|---|---|

| 3D Porous Scaffolds | ATP Assay | Complete lysis of deep cells; no penetration barrier for reagents. | Homogenization ensures all cells are lysed and measured. |

| Electrospun Fibers | ATP Assay | Low autofluorescence & minimal chemical interaction. | Avoids optical interference common in colorimetric/fluorescent assays. |

| Hydrogel Encapsulation | ATP Assay | Sensitive detection of low cell numbers at early time points. | Superior sensitivity tracks initial seeding efficiency and early proliferation. |

| High-Throughput Screening | ATP Assay | Speed, simplicity, and homogenous format. | 96/384-well compatible; results in < 10 minutes post-lysis. |

Detailed Protocol: ATP Assay for 3D Biomaterial Scaffolds

Objective: To accurately quantify viable, metabolically active cells cultured on or within a 3D biomaterial scaffold.

I. Materials & Reagent Solutions

The Scientist's Toolkit:

| Item | Function |

|---|---|

| Bioluminescent ATP Assay Kit | Contains cell lysis reagent, ATP standard, stable luciferin/luciferase substrate. |

| Triton X-100 (0.1% in PBS) | Alternative lysis agent for sensitive biomaterials. |

| ATP Standard (1mM stock) | For generating a standard curve to convert RLU to ATP moles. |

| White, Opaque 96-well Plate | Prevents optical cross-talk; maximizes light signal capture. |

| Luminometer | Instrument to measure Relative Light Units (RLU). |

| Tissue Homogenizer (sonicator) | Essential for complete cell lysis within 3D scaffolds. |

| Cell Culture Media (Phenol Red-free) | Recommended to remove potential quenching agents. |

II. Experimental Workflow Protocol

Sample Preparation:

- Seed cells onto/into biomaterial scaffolds in a 24-well plate. Include scaffold-only controls.

- At assay endpoint, gently wash scaffolds 2x with PBS to remove non-adherent/dead cells.

- Transfer each scaffold to a sterile microcentrifuge tube.

Cell Lysis:

- Add 200 µL of ATP assay lysis buffer (or 0.1% Triton X-100) to each tube.

- For 3D scaffolds: Homogenize using a brief soniciation pulse (5-10 sec at 20% amplitude) or mechanical disruption.

- Incubate for 10 minutes at room temperature with gentle agitation.

- Centrifuge at 12,000g for 2 minutes to pellet scaffold debris and cellular fragments.

ATP Reaction & Measurement:

- Prepare ATP standard curve (typically 10^-6 to 10^-11 M) in lysis buffer.

- Transfer 50 µL of each supernatant (sample and standard) to a white opaque 96-well plate, in triplicate.

- Equilibrate the lyophilized substrate to room temperature and reconstitute as per kit instructions.

- Using an injector or multichannel pipette, add 50 µL of substrate to each well.

- Shake the plate for 30 seconds, wait 2 minutes for signal stabilization, and measure luminescence (RLU) in a luminometer with a 1-second integration time.

Data Analysis:

- Generate a linear fit from the ATP standard curve (Log[ATP] vs. Log[RLU]).

- Interpolate sample RLU values to calculate ATP concentration.

- Normalize data to scaffold mass/volume or protein content, or present as moles ATP per scaffold.

Visualization: Experimental Workflow & Key Advantage Mechanism

Diagram 1: ATP Assay Protocol Workflow and Signal Generation

Diagram 2: Specificity Advantage of ATP vs. Redox Assays

The bioluminescence reaction catalyzed by firefly luciferase (Photinus pyralis) is a cornerstone technology for quantifying adenosine triphosphate (ATP). In biomaterial cell viability research, the amount of ATP serves as a direct indicator of metabolically active cells. When mammalian cells are cultured on or within biomaterials, their viability and proliferation are critical metrics for assessing biocompatibility and functional performance. The luciferase-mediated oxidation of D-luciferin is exquisitely ATP-dependent, producing light proportional to the ATP concentration, thus providing a sensitive, non-destructive means to monitor cell health on biomaterial scaffolds over time.

The Biochemical Reaction: Mechanism and Key Components

The reaction occurs in two primary steps:

- Adenylation: Luciferase activates D-luciferin with ATP, forming luciferyl-adenylate and inorganic pyrophosphate (PPi).

- Oxidation: The luciferyl-adenylate is oxidized by molecular oxygen, yielding oxyluciferin in an electronically excited state, carbon dioxide (CO₂), and AMP. The decay of oxyluciferin to its ground state results in the emission of a photon (λmax ~560 nm, yellow-green light).

Diagram Title: Firefly Luciferase Catalytic Mechanism

Quantitative Reaction Parameters

Table 1: Key Kinetic and Spectral Parameters of Firefly Luciferase (from P. pyralis)

| Parameter | Value | Condition / Note |

|---|---|---|

| Km for ATP | 60 – 150 µM | Varies with pH, [Mg²⁺], and [Luciferin] |

| Km for D-Luciferin | 5 – 10 µM | At saturating ATP levels |

| Peak Emission (λmax) | ~560 nm | pH 7.8, yellow-green |

| Red-Shifted Emission | ~610 nm | pH <7.0, lower quantum yield |

| Quantum Yield | 0.41 – 0.88 | Photons per luciferin molecule |

| Optimal pH | 7.5 – 8.5 | Activity declines sharply below pH 7.0 |

| Essential Cofactor | Mg²⁺ | Required at ~2-10 mM concentration |

Research Reagent Solutions Toolkit

Table 2: Essential Reagents for ATP-Dependent Bioluminescence Assays

| Item | Function & Importance |

|---|---|

| Recombinant Firefly Luciferase | Purified enzyme for in vitro assays. High specific activity is critical for sensitivity. |

| Cell-Lysis Compatible Luciferase Reporter | Luciferase gene (e.g., pGL4 vectors) for stable or transient expression in cells cultured on biomaterials. |

| D-Luciferin (Potassium Salt) | Cell-permeable substrate. Potassium salt offers superior solubility and stability in aqueous buffers. |

| ATP Standard Solution | High-purity ATP for generating a standard curve to quantify unknown ATP concentrations in samples. |

| Cell Lysis Buffer (ATP-compatible) | Non-ionic detergent-based buffer (e.g., Triton X-100) to release intracellular ATP without rapid degradation. Must inhibit endogenous ATPases. |

| ATPase/Apyrase Inhibitors | Compounds (e.g., sodium azide, apyrase inhibitors) added to lysis buffer to stabilize ATP post-cell lysis. |

| Reconstitution Buffer | Optimized buffer (pH 7.8, containing Mg²⁺, DTT, coenzyme A) to provide ideal conditions for the luciferase reaction. CoA enhances light output stability. |

| White/Wall Opaque Multiwell Plates | Prevents optical crosstalk between wells, maximizing signal capture and assay sensitivity. |

| Recombinant Apyrase | Enzyme that degrades ATP; used as a negative control or to quench reactions. |

Detailed Protocols for Biomaterial Cell Viability Assessment

Protocol 4.1: Standard ATP Detection Assay for 2D Biomaterial Coatings

Objective: To quantify viable cell number on planar biomaterial coatings via ATP content.

Workflow:

Diagram Title: ATP Assay Workflow for 2D Coatings

Materials:

- Biomaterial-coated 96-well plate with cells.

- ATP Assay Kit (lysis-compatible) or components from Table 2.

- Dulbecco’s Phosphate Buffered Saline (DPBS).

- Luminometer with injector (or pre-mix method).

Procedure:

- Cell Preparation: Culture cells on the test biomaterial-coated plates for the desired duration (e.g., 1, 3, 7 days).

- Reagent Equilibration: Remove culture medium. Gently rinse cells with DPBS. Add 50-100 µL of ATP-compatible lysis buffer per well. Shake for 5 minutes at room temperature to lyse cells and stabilize ATP.

- Reaction Initiation: Program the luminometer to inject 50 µL of luciferase/D-luciferin reagent into each well. OR, pre-mix reagent with an equal volume of lysate in a separate opaque plate.

- Measurement: Read luminescence immediately after injection/mixing. Use an integration time of 1-10 seconds.

- Standard Curve: Prepare a dilution series of ATP standard (e.g., 10 µM to 10 nM) in lysis buffer. Process alongside samples.

- Analysis: Plot RLU vs. ATP concentration for the standard curve. Use the linear regression equation to calculate ATP in unknown samples. Normalize to a cell number standard or protein content.

Protocol 4.2: 3D Biomaterial Scaffold Viability Assay (ATP Extraction)

Objective: To measure cell viability within three-dimensional biomaterial scaffolds (e.g., hydrogels, porous matrices).

Materials:

- 3D scaffolds seeded with cells.

- ATP assay lysis buffer with strong detergents (e.g., 1% Triton X-100, 0.5% CHAPS).

- Mechanical homogenizer (e.g., pellet pestle) or ultrasonic cell disruptor (for tough scaffolds).

- Refrigerated microcentrifuge.

Procedure:

- Sample Harvest: At assay time point, transfer each 3D scaffold to a labeled microcentrifuge tube.

- ATP Extraction: Add 200-500 µL of ice-cold lysis buffer. Homogenize thoroughly using a pellet pestle or brief sonication on ice (3 x 5 second pulses). The goal is complete scaffold disintegration and cell lysis.

- Clarification: Centrifuge at 12,000 x g for 5 minutes at 4°C to pellet scaffold debris and insoluble material.

- Assay: Transfer the clear supernatant to a new tube. Proceed with Steps 3-6 from Protocol 4.1, using the supernatant as the sample. Note: Dilution of the supernatant may be necessary if the signal exceeds the standard curve range.

- Normalization: Normalize ATP values to scaffold dry weight, DNA content, or total protein from a parallel sample.

Key Considerations for Biomaterial Research

- Background Luminescence: Test the biomaterial alone for auto-luminescence or quenching effects.

- Cell Retrieval vs. In-situ Lysis: For porous 3D scaffolds, in-situ lysis is preferred. For stiff materials, cells may need to be enzymatically detached first, which can affect ATP levels.

- Kinetics: The "flash" kinetics of firefly luciferase require rapid measurement after reagent addition. Using coenzyme A in the reagent mix promotes "glow" kinetics for more stable signals.

- Normalization: ATP data should be complemented with other viability assays (e.g., DNA quantification, metabolic activity) for a comprehensive view of cell health on the biomaterial.

Within the broader thesis on ATP detection assays for biomaterial cell viability research, understanding the material-specific variables that interfere with assay chemistry is paramount. ATP assays, predominantly based on firefly luciferase bioluminescence, are highly sensitive but susceptible to interference from biomaterial properties, leading to inaccurate viability readouts. This document details these considerations, provides validated mitigation protocols, and offers standardized workflows for reliable data generation.

Key Biomaterial Properties and Their Impact on ATP Assays

The following table summarizes the primary biomaterial properties and their demonstrated quantitative impact on ATP assay luminescence signals.

Table 1: Biomaterial Properties and Their Impact on ATP Assay Signals

| Property | Mechanism of Interference | Typical Signal Deviation Range | Direction of Effect |

|---|---|---|---|

| Surface Charge (Zeta Potential) | Adsorption of luciferase enzyme or ATP molecules onto material surface. | -80% to +300% vs. control | Variable (↑ or ↓) |

| Porosity / Surface Area | Non-specific binding of assay components; altered cell seeding density/attachment. | -60% to +50% | Predominantly ↓ |

| Material Color / Autofluorescence | Optical interference at emission wavelength (~560 nm); light absorption/quenching. | -95% to +20% | Predominantly ↓ |

| Hydrophobicity | Altered cell adhesion/spreading affecting metabolism; reagent wetting issues. | -70% to +40% | Variable |

| Degradation Products (e.g., ions, monomers) | Chelation of Mg²⁺ (essential cofactor); direct enzyme inhibition. | -99% to -30% | ↓ |

| Material Roughness (Ra) | Inconsistent cell distribution; local pH or oxygen gradients. | -40% to +25% | Variable |

Experimental Protocol: Interference Screening for Novel Biomaterials

Objective: To systematically test a novel biomaterial for interference in a standard ATP viability assay. Materials: Test biomaterial (film, scaffold, particles), control material (standard TCP), cultured cells, ATP assay kit (luciferin/luciferase), cell culture medium, phosphate-buffered saline (PBS), white opaque assay plate, luminometer.

Procedure:

- Material Preparation: Sterilize test and control materials according to standard protocols. Place in wells of a white opaque 96-well plate. If solid, ensure flat contact with well bottom.

- Background Luminescence Check (CRITICAL STEP):

- Add complete assay reagent (luciferin/luciferase) to wells containing only material and culture medium (no cells).

- Incubate for the standard assay period (e.g., 10 min).

- Measure luminescence (RLU). Record values as

Material Background (MBG).

- Cell-Seeding & Culture: Seed cells at standard density (e.g., 5,000-10,000 cells/well) in complete medium. Include wells with cells on control material and cell-free wells for background. Culture for desired period (e.g., 24-72h).

- ATP Assay Execution:

- Equilibrate assay kit reagents to room temperature.

- Prepare the ATP standard curve in solution (no material) per kit instructions.

- Aspirate medium from test/control wells.

- Add recommended volume of diluted assay reagent to each well.

- Shake orbitally for 5 minutes to induce cell lysis.

- Incubate in dark for 10 minutes to stabilize signal.

- Measure luminescence in a plate-reading luminometer.

- Data Correction: For each test material well, calculate corrected RLU:

Corrected RLU = Total Measured RLU - MBG - Cell-Free Medium Background.- Convert corrected RLU to ATP concentration using the standard curve generated in solution.

- Validation: Compare ATP concentration from cells on test material to control material. Confirm with a complementary viability assay (e.g., Calcein-AM).

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents and Materials for ATP Assays on Biomaterials

| Item | Function & Rationale |

|---|---|

| White Opaque Multiwell Plates | Maximizes light signal collection for luminescence; prevents cross-talk between wells. |

| ATP Assay Kit with Non-lytic Buffer | Allows sequential monitoring of the same sample; crucial for 3D scaffolds where cell retrieval is difficult. |

| Recombinant Firefly Luciferase (lyophilized) | For spike-and-recovery experiments to test for enzyme inhibition by material leachates. |

| ATP Standard (aqueous solution) | Essential for generating a standard curve in solution to quantify absolute ATP, independent of material effects. |

| Mg²⁺ Supplement Solution | To counteract potential chelation by material degradation products (e.g., from bioceramics). |

| Detergent-Based Lysis Buffer (alternative) | Provides complete cell lysis for difficult-to-lyse cells or dense 3D constructs, ensuring total ATP release. |

| Bovine Serum Albumin (BSA) 1-5% Solution | Can be used to pre-coat materials or add to assay buffer to reduce non-specific protein (luciferase) adsorption. |

Diagram: Workflow for Validating ATP Assays on Biomaterials

Title: ATP Assay Validation Workflow for Biomaterials

Diagram: Mechanisms of Biomaterial Interference in ATP Assay

Title: Mechanisms of Biomaterial Interference in ATP Assay

Step-by-Step Protocol: Performing ATP Assays on 2D, 3D, and Complex Biomaterial Scaffolds

Within a thesis focused on ATP detection assays for biomaterial cell viability research, the pre-assay phase is critical. The accuracy of luminescent ATP quantification, which reflects metabolically active cell count, is directly contingent upon standardized sample preparation and precise cell seeding. This document provides detailed application notes and protocols to ensure reproducibility and validity in biomaterial-based cytotoxicity, proliferation, and biocompatibility studies.

Key Research Reagent Solutions & Materials

The following table details essential materials for sample preparation and seeding prior to an ATP viability assay.

Table 1: Essential Materials and Reagents for Pre-Assay Planning

| Item | Function & Rationale |

|---|---|

| Sterile Biomaterial Substrates (e.g., polymer films, hydrogels, metal/ceramic discs) | The test substrate must be sterile and compatible with cell culture. Materials are often cut to fit standard multi-well plate formats. |

| Cell Culture Medium (with serum, if appropriate) | Maintains cell viability during the seeding and attachment phase. Serum may enhance initial attachment on challenging surfaces. |

| Serum-Free/Reduced Serum Medium | Used for serum-starvation synchronization or for assays where serum enzymes might interfere with subsequent steps. |

| Phosphate-Buffered Saline (PBS), Sterile | For rinsing biomaterials and cells without osmotic shock. Calcium- and magnesium-free PBS is used for enzymatic detachment. |

| Trypsin-EDTA or Enzyme-Free Dissociation Buffer | For detaching adherent cells from culture flasks to create single-cell suspensions for accurate counting and seeding. |

| Trypan Blue Solution (0.4%) | Vital dye used in conjunction with a hemocytometer or automated cell counter to distinguish viable from non-viable cells in suspension. |

| Automated Cell Counter or Hemocytometer | Essential for determining exact cell concentration (cells/mL) to ensure consistent seeding density across all biomaterial samples and controls. |

| Tissue Culture-Treated Multi-Well Plates | Standard plates serve as positive control surfaces (TCPS) and holders for biomaterial samples. |

| Bio-Compatible Adhesive or Sample Holders | To secure non-integral biomaterials (e.g., discs) to the bottom of the well, preventing floating and ensuring even cell exposure. |

| Laminar Flow Hood (Biosafety Cabinet) | Provides an aseptic environment for all procedures to prevent microbial contamination. |

| Humidified CO2 Incubator (37°C, 5% CO2) | Maintains physiological conditions for cell attachment and growth on the biomaterial post-seeding. |

Protocols for Sample Preparation & Cell Seeding

Protocol: Biomaterial Sterilization and Equilibration

- Objective: To prepare sterile biomaterial samples that are physiologically compatible for cell culture.

- Materials: Biomaterial samples, 70% ethanol, sterile PBS, cell culture medium, multi-well plate.

- Procedure:

- Sterilization: For non-degradable, stable materials (e.g., metals, certain polymers), immerse in 70% ethanol for 15-30 minutes. For sensitive materials (e.g., many hydrogels, biodegradable polymers), use UV irradiation (30-60 mins per side) or antibiotic/antimycotic solution soak.

- Rinsing: Aseptically rinse samples 3x with sterile PBS to remove residual sterilant.

- Equilibration: Incubate samples in pre-warmed cell culture medium (without cells) for a minimum of 1 hour (or as material-specific literature dictates) in the CO2 incubator. This allows temperature, pH, and hydration stabilization.

- Plating: Place each equilibrated biomaterial sample into a well of a multi-well plate. Secure if necessary.

Protocol: Generation of Single-Cell Suspension for Seeding

- Objective: To obtain a suspension of viable, single cells at a known concentration.

- Materials: Adherent cell culture, PBS, trypsin-EDTA, complete medium, centrifuge, cell counter.

- Procedure:

- Rinse: Remove medium from culture flask and rinse cell monolayer gently with pre-warmed PBS.

- Detach: Add enough pre-warmed trypsin-EDTA to cover the monolayer (e.g., 2-3 mL for a T75 flask). Incubate at 37°C until cells detach (typically 3-5 minutes).

- Neutralize: Add double the volume of complete medium (containing serum) to inactivate the trypsin.

- Centrifuge: Transfer cell suspension to a conical tube. Centrifuge at 200 x g for 5 minutes. Aspirate supernatant.

- Resuspend & Count: Resuspend cell pellet in a known volume of fresh medium. Mix an aliquot with Trypan Blue (typically 1:1). Count viable (unstained) cells using a hemocytometer or automated counter.

- Calculate & Dilute: Calculate cell concentration (cells/mL). Dilute suspension with medium to achieve the desired working concentration for seeding (e.g., 50,000 cells/mL).

Protocol: Seeding Cells onto Biomaterial Samples

- Objective: To achieve uniform, known-density cell attachment on biomaterial test samples and control surfaces.

- Materials: Prepared biomaterial samples in plate, cell suspension, control wells (TCPS), pipettes.

- Procedure:

- Seed: Gently agitate the cell suspension. Aspirate the equilibration medium from the biomaterial sample well. Immediately pipette the calculated volume of cell suspension directly onto the center of the sample. For a 24-well plate, a typical seeding volume is 500 µL.

- Control: Seed identical cell numbers into empty, tissue culture-treated wells as positive controls.

- Distribute: Gently rock the plate in a cross-shaped pattern to evenly distribute cells over the sample surface.

- Incubate: Place the plate in the CO2 incubator and allow cells to attach for the prescribed period (e.g., 4-24 hours, depending on cell type and material).

- Post-Seeding Check: After the attachment period, microscopically check a subset of samples for cell attachment and distribution before proceeding to the ATP assay.

Data Presentation: Pre-Assay Planning Parameters

Table 2: Critical Parameters for Seeding Common Cell Lines on Biomaterials

| Cell Line | Recommended Seeding Density (for 24-well plate) | Key Attachment Factors | Typical Attachment Time Prior to Assay |

|---|---|---|---|

| Human Mesenchymal Stem Cells (hMSCs) | 10,000 - 25,000 cells/cm² | Surface topography, protein pre-coating (e.g., fibronectin) | 6-24 hours |

| MC3T3-E1 (Osteoblast precursor) | 20,000 - 50,000 cells/cm² | Surface hydrophilicity, roughness | 4-6 hours |

| L929 (Fibroblast) | 10,000 - 30,000 cells/cm² | General biocompatibility, serum presence | 4-6 hours |

| Saos-2 (Osteosarcoma) | 25,000 - 50,000 cells/cm² | Standard culture conditions | 4-6 hours |

| Primary Human Osteoblasts (HOBs) | 15,000 - 30,000 cells/cm² | Crucial need for serum or specific adhesion factors | 12-24 hours |

Visualized Workflows

Biomaterial and Cell Prep Workflow for ATP Assay

ATP Detection Link to Cell Viability

Within a broader thesis on ATP detection assays for biomaterial cell viability research, the optimization of cell lysis is a critical, yet often overlooked, pre-analytical step. The accurate quantification of cellular ATP, a direct indicator of metabolically active cells, is fundamentally dependent on the complete and consistent release of intracellular ATP into the assay solution. This challenge is compounded when cells are cultured on diverse biomaterial substrates (e.g., polymers, hydrogels, metal alloys, ceramics), as material surface properties (wettability, porosity, charge) can significantly impact lysis reagent efficiency. Incomplete lysis leads to underestimated ATP values, directly confounding viability data and compromising comparisons between materials. This application note provides a systematic framework and validated protocols to ensure complete ATP release, thereby enhancing the reliability and reproducibility of viability assays in biomaterial screening and drug development.

Key Challenges & Principles of Optimal Lysis

- Material Interference: Hydrophobic or porous materials can sequester lysis reagents or cells, creating physical barriers to efficient lysis.

- ATP Degradation: Endogenous ATPases released during lysis can rapidly degrade ATP if not instantaneously inhibited.

- Quenching of Luminescence: Certain material leachates or surface chemistries can quench the luciferase-luciferin reaction used in detection.

- Principles for Optimization: The optimal lysis method must 1) rapidly permeabilize all cell membranes, 2) instantaneously inhibit ATPases, 3) be compatible with the material substrate, and 4) not interfere with the subsequent detection chemistry.

Comparative Analysis of Lysis Methods

Data from recent studies (2023-2024) comparing common lysis approaches for cells on polystyrene (standard) and polycaprolactone (PCL, a hydrophobic polymer) are summarized below.

Table 1: Efficacy of Lysis Buffers on Different Material Surfaces

| Lysis Method / Buffer | Key Components | Reported ATP Recovery on Polystyrene (%) | Reported ATP Recovery on PCL (%) | Advantages | Drawbacks for Biomaterials |

|---|---|---|---|---|---|

| Detergent-based (Broad-spectrum) | Triton X-100, ATPase inhibitors | 100 ± 5 (Reference) | 75 ± 15 | Rapid, effective for standard surfaces. | Poor efficiency on hydrophobic surfaces; can quench luminescence. |

| Organic Solvent-based | 1% DMSO in water | 95 ± 4 | 90 ± 8 | Effective on hydrophobic materials. | Volatility; can damage some polymeric materials. |

| Apyrase-based Enzymatic | Apyrase (nucleotidase) in mild buffer | 98 ± 3 | 85 ± 10 | Gentle; material-friendly. | Slower; may not fully lyse dense cell layers. |

| Commercial ATP-assay Lysis Buffer | Proprietary surfactants, stabilizers, ATPase inhibitors | 102 ± 4 | 95 ± 5* | Optimized for detection; highly reproducible. | Cost; proprietary composition. |

| Freeze-Thaw Cyclic Lysis | Repeated freezing (-80°C) & thawing | 80 ± 12 | 65 ± 18 | No chemical additives. | Incomplete; highly variable; promotes ATP degradation. |

*Data from a 2024 study optimizing lysis for 3D printed PCL scaffolds.

Table 2: Impact of Incubation Parameters on Lysis Efficiency

| Parameter | Standard Protocol | Optimized Protocol (for challenging materials) | Rationale |

|---|---|---|---|

| Lysis Buffer Volume | 100 µl per 10,000 cells | 150-200 µl per 10,000 cells | Ensures complete coverage of uneven or porous material surfaces. |

| Incubation Temperature | Room Temperature (RT) | 37°C | Enhances surfactant activity and membrane fluidity for better permeabilization. |

| Incubation Time | 5-10 minutes at RT | 10-15 minutes at 37°C with gentle orbital shaking | Allows buffer to penetrate material microstructure and cell layers. |

| Agitation | None | Low-speed orbital shaking (200 rpm) | Prevents localized depletion and improves contact on non-wetting surfaces. |

Detailed Protocols

Protocol A: Standardized Lysis for Planar, Non-Porous Biomaterials

This protocol is suitable for flat, well-characterized materials like tissue culture plastic, glass, or dense metal alloys.

I. Materials & Reagents

- Test biomaterial samples with adhered cells.

- ATP detection kit (e.g., CellTiter-Glo 2.0, ViaLight Plus).

- Optimized Lysis Buffer: Use the detergent-based lysis reagent provided with the ATP kit. Supplement with 0.5% (v/v) Triton X-100 and 1 mM DTT if the kit reagent is mild.

- Microplate reader (luminescence-capable) or luminometer.

- Orbital shaker (for microplates).

II. Procedure

- Culture & Treatment: Culture cells on the test biomaterials in a suitable multiwell plate format until desired confluence. Apply experimental treatments.

- Equilibration: Equilibrate the ATP assay lytic reagent and the plate to room temperature for 30 minutes.

- Lysis: For each well, add a volume of lysis reagent equal to the original culture medium volume.

- Incubation with Agitation: Seal the plate and incubate on an orbital shaker (200-300 rpm) at room temperature for 15 minutes. This step is critical for consistent release.

- Signal Stabilization: Allow the plate to stand at room temperature for an additional 5 minutes to reduce bubble formation.

- Detection: Transfer an aliquot (e.g., 100 µL) to a white opaque microplate or read the original plate. Measure luminescence according to the detector's protocol.

Protocol B: Enhanced Lysis for Porous or Hydrophobic Biomaterials

This protocol is designed for challenging materials like fibrous scaffolds, hydrophobic polymers, or rough-surface implants.

I. Materials & Reagents

- All materials from Protocol A.

- Enhanced Lysis Buffer: Prepare a solution of the commercial ATP lysis reagent mixed 1:1 with a 0.1% (w/v) SDS solution containing 5 mM MgCl₂ and 0.1% (v/v) Tween 80. Note: Test for assay compatibility first.

- Water bath or incubator (37°C).

II. Procedure

- Culture & Treatment: As in Protocol A. After treatment, gently rinse scaffolds/implants with PBS to remove non-adherent cells.

- Buffer Application: Apply 200-300 µL of Enhanced Lysis Buffer per sample, ensuring complete immersion of porous or 3D structures.

- Warm Incubation with Agitation: Incubate the plate at 37°C for 20-25 minutes with continuous orbital shaking (150-200 rpm).

- Lysate Transfer: For 3D scaffolds, carefully transfer the total lysate (now containing released ATP) to a fresh microplate well. Centrifuge briefly (1000 x g, 2 min) to pellet any detached material or bubbles if necessary.

- Detection: Proceed with luminescence measurement as in Protocol A, Step 6.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for ATP Lysis Optimization

| Item / Reagent | Function in Lysis Optimization | Key Consideration |

|---|---|---|

| Commercial ATP Lysis Buffer (e.g., from Promega, Lonza) | Proprietary mix of detergents, ATPase inhibitors, and stabilizers; gold standard for reproducibility. | Use as a base; can be supplemented for difficult materials. |

| Triton X-100 | Non-ionic surfactant that disrupts lipid bilayers effectively. | Can quench luminescence at high concentrations (>0.5%). |

| Tween 80 | Non-ionic surfactant with better compatibility on hydrophobic surfaces. | Milder than Triton; good for pre-wetting hydrophobic materials. |

| Sodium Dodecyl Sulfate (SDS) | Ionic detergent providing powerful lysis. | Highly inhibitory to luciferase. Must be diluted below critical micelle concentration (<0.01%) before detection. |

| Dimethyl Sulfoxide (DMSO) | Organic solvent that permeabilizes membranes and solubilizes hydrophobic surfaces. | Can extract interfering compounds from some polymers. |

| Apyrase (ATP-diphosphohydrolase) | Enzyme that degrades extracellular ATP; used in control experiments to confirm lysis is intracellular. | Critical for validating that signal is from viable cells, not extracellular ATP. |

| ATPase Inhibitors (e.g., Sodium Azide, DTT) | Inhibit enzymatic degradation of ATP post-lysis. | Often included in commercial buffers. Essential for accurate quantification. |

| White, Opaque, Low-Binding Microplates | Maximize luminescence signal capture and minimize analyte adsorption. | Crucial for low-cell-number assays on materials. |

Visualizations

Workflow for ATP Viability Assay on Biomaterials

Material Properties Affecting Lysis Efficiency

Standard Operating Procedure for a 96-Well Plate Luminescence Assay

Within the broader thesis investigating biomaterial-cell interactions, accurately quantifying cell viability is paramount. A luminescent ATP detection assay provides a rapid, sensitive, and high-throughput method to determine the number of viable cells based on the quantification of adenosine triphosphate (ATP), the primary energy currency of metabolically active cells. This SOP outlines a standardized protocol for performing this assay in a 96-well plate format, enabling consistent evaluation of cell viability on novel biomaterial surfaces or in response to drug treatments.

Key Principles and Recent Data

ATP is present in all metabolically active cells. Upon cell lysis, released ATP reacts with luciferase and its substrate D-luciferin, producing light proportional to the ATP concentration. Recent optimizations have enhanced assay stability and sensitivity.

Table 1: Comparison of Commercial ATP Luminescence Assay Kits (Representative Data)

| Kit Name / Provider | Linear Range | Sensitivity (Detection Limit) | Luminescence Half-Life | Key Feature for Biomaterial Research |

|---|---|---|---|---|

| CellTiter-Glo 3D (Promega) | 1-10,000 cells (typical) | < 10 cells/well | > 5 hours | Optimized for 3D cultures & lyses biomaterial matrices. |

| ATP Lite 1step (PerkinElmer) | 0.1 nM – 10 µM ATP | ~0.1 nM ATP | > 3 hours | Homogeneous "add-and-read" protocol. |

| ViaLight Plus (Lonza) | 1-50,000 cells | 1-2 cells/well | > 30 minutes | Designed for cytotoxicity & proliferation. |

Research Reagent Solutions & Essential Materials

Table 2: The Scientist's Toolkit for ATP Luminescence Assay

| Item | Function & Brief Explanation |

|---|---|

| ATP Luminescence Assay Kit (e.g., CellTiter-Glo 2.0) | Contains the proprietary stable luciferase reagent, lysing cells and generating luminescent signal. |

| White/Clear-Bottom 96-Well Plate | White plates maximize light signal reflection; clear bottoms allow prior microscopic observation. |

| Sterile Tissue Culture Plate (for cell seeding) | For cell growth on biomaterials or drug treatment prior to assay. |

| ATP Standard (if included) | For generating a standard curve to convert RLU to ATP concentration. |

| Automated Plate Dispenser or Multichannel Pipette | Ensures rapid, uniform addition of reagent to wells for kinetic consistency. |

| Plate Shaker (orbital) | Ensures thorough mixing of reagent with cell culture medium. |

| Microplate Luminometer | Instrument to measure Relative Light Units (RLU) from each well. |

| Mammalian Cell Line (e.g., hMSCs, HEK293) | Relevant cell model for biomaterial or drug testing. |

| Test Biomaterials or Compounds | The independent variable(s) in the viability experiment. |

Detailed Protocol

Experiment 1: Standard Protocol for 2D Cell Viability on Biomaterials

Objective: To determine the viability of cells seeded directly onto test biomaterial films or coatings deposited in a 96-well plate.

Materials:

- ATP luminescence assay kit.

- Cells in log-phase growth.

- 96-well plate with pre-deposited biomaterial coatings and control wells.

- Complete cell culture medium.

- Luminometer compatible with 96-well plates.

Methodology:

- Cell Seeding & Treatment: Seed a defined number of cells (e.g., 5,000 cells/well in 100 µL medium) directly onto biomaterial-coated wells. Include cell-only control wells (tissue culture plastic) and medium-only blanks. Culture for desired period (e.g., 24, 48, 72 h).

- Equipment & Reagent Preparation: Warm the assay kit buffer to room temperature. Reconstitute the lyophilized substrate if necessary. Equilibrate the plate to room temperature (~30 min) before assay.

- Reagent Addition: Add an equal volume of reconstituted luminescence reagent to each well (e.g., 100 µL reagent to 100 µL medium). Use an automated dispenser or multichannel pipette for speed.

- Mixing & Lysis: Place plate on an orbital shaker for 2 minutes at 300-500 rpm to induce cell lysis and ensure homogeneity.

- Incubation: Incubate plate at room temperature for 10 minutes to stabilize the luminescent signal.

- Signal Measurement: Read luminescence on a plate-reading luminometer with an integration time of 0.25-1 second per well. Record data as Relative Light Units (RLU).

Experiment 2: Protocol for 3D Culture or Biomaterial Scaffold Analysis

Objective: To assess viability of cells encapsulated within or seeded on 3D biomaterial scaffolds.

Modified Methodology:

- Scaffold Preparation: Place 3D scaffolds (e.g., hydrogels, porous matrices) in wells of a low-attachment 96-well plate. Seed cells on/in scaffolds.

- Assay Adjustment: Use an assay kit specifically optimized for 3D cultures (e.g., CellTiter-Glo 3D), which contains a more potent lysis agent to penetrate the matrix.

- Volume Ratios: The reagent volume may need to be increased (e.g., 150 µL reagent to 50-100 µL medium-covered scaffold) to fully immerse the scaffold.

- Extended Mixing: Shake for 5-10 minutes to ensure complete lysis of cells within the 3D structure.

- Signal Measurement: Proceed as in Experiment 1. Note: signal stabilization time may be longer.

Data Analysis

- Background Subtraction: Subtract the average RLU of the medium-only blank wells from all sample readings.

- Standard Curve (Optional): If absolute ATP quantification is needed, generate a curve using ATP standards and fit data (typically linear or quadratic regression).

- Viability Calculation: Calculate relative viability as:

(Mean RLU of Treated Sample / Mean RLU of Untreated Control) x 100%. - Statistical Analysis: Perform appropriate tests (e.g., one-way ANOVA with post-hoc test) on replicate values (typically n≥6).

Visualization of Workflow and Pathways

Diagram 1 Title: ATP Luminescence Assay Workflow & Reaction Pathway

Adapting Protocols for 3D Hydrogels, Porous Scaffolds, and Electrospun Matrices

Within the broader thesis on developing a standardized ATP detection assay for biomaterial cell viability research, significant protocol adaptations are required for three-dimensional (3D) culture systems. This application note details the methodological adjustments necessary for accurate and reproducible ATP-based viability assessment in 3D hydrogels, porous scaffolds, and electrospun matrices, which present unique challenges in diffusion, cell distribution, and reagent penetration compared to 2D cultures.

ATP bioluminescence assays are the gold standard for quantifying viable cell numbers due to ATP's rapid degradation upon cell death. However, translating 2D ATP assay protocols to 3D biomaterial constructs is non-trivial. The complex microstructure of these materials impedes uniform cell seeding, limits reagent diffusion, and can cause signal quenching, leading to inaccurate viability readings. This document provides standardized adaptations to overcome these barriers, ensuring reliable data for tissue engineering and drug screening applications.

Table 1: Key Physical Parameters and Assay Challenges of 3D Biomaterials

| Biomaterial Type | Avg. Pore Size (µm) | Diffusion Coefficient (D/D₀)† | Recommended Cell Seeding Density (cells/cm³) | Critical Lysis Time (min) |

|---|---|---|---|---|

| Hydrogel (e.g., Alginate) | 10 - 100 | 0.3 - 0.7 | 1x10⁶ - 5x10⁶ | 30 - 45 |

| Porous Scaffold (e.g., PCL) | 150 - 300 | 0.5 - 0.8 | 2x10⁶ - 1x10⁷ | 45 - 60 |

| Electrospun Matrix | 5 - 50 (fiber spacing) | 0.1 - 0.4 | 5x10⁵ - 2x10⁶ | 60 - 90 |

† D/D₀: Relative diffusion coefficient of ATP assay reagents in the material compared to in free solution.

Table 2: ATP Assay Recovery Rate and Signal Linearity in 3D Systems

| System | Recovery Rate vs. 2D Control* | Linear Range (ATP concentration) | R² Value (Typical) | Required Signal Correction |

|---|---|---|---|---|

| 2D Monolayer | 100% | 10⁻¹² – 10⁻⁶ M | >0.99 | None |

| Hydrogel (200 µm thick) | 75 ± 10% | 10⁻¹¹ – 10⁻⁶ M | 0.98 | Matrix quenching factor |

| Porous Scaffold (2mm cube) | 60 ± 15% | 10⁻¹⁰ – 10⁻⁶ M | 0.96 | Diffusion & porosity factor |

| Electrospun Mat (100 µm thick) | 50 ± 12% | 10⁻¹⁰ – 10⁻⁶ M | 0.95 | Fiber adsorption factor |

Recovery Rate: Percentage of ATP signal detected from a known number of lysed cells in the 3D system compared to an equivalent 2D sample.

Adapted Experimental Protocols

Protocol 1: Standardized Cell Seeding for 3D Constructs

Objective: Ensure uniform cell distribution prior to ATP assay.

- Hydrogels: Mix cell suspension directly with polymer precursor (e.g., 2% alginate, 1% fibrinogen). Crosslink (e.g., with CaCl₂ for alginate) to form cylindrical discs (5mm diameter x 2mm height).

- Porous Scaffolds: Pre-wet scaffolds (e.g., PLGA, PCL) in culture medium. Use dynamic seeding: incubate scaffolds with cell suspension on an orbital shaker (50 rpm, 2 hours). Follow with static culture for 24h to allow attachment.

- Electrospun Mats: Place mats on transwell inserts. Seed cells dropwise in a low volume (20 µL per 5mm disc) to the center. Allow 4h for attachment before adding medium to the lower chamber. Note: Seed a parallel set of 2D wells at an equivalent density for normalization.

Protocol 2: ATP Extraction and Luminescence Measurement for 3D Materials

Objective: Completely lyse cells and extract ATP without material interference.

- Lysis Buffer Preparation: Prepare a detergent-based lysis buffer (e.g., containing 1% Triton X-100 in PBS). For dense electrospun mats, add 0.1% collagenase type I (for protein-based fibers) to enhance penetration.

- Lysis Process:

- Transfer each 3D construct to a separate well of a white-walled, opaque-bottom 96-well plate.

- Hydrogels/Porous Scaffolds: Add 200 µL of lysis buffer per construct. Incubate on a plate shaker (300 rpm) at room temperature for 45 minutes.

- Electrospun Mats: Completely submerge in 150 µL lysis buffer. Sonicate in a water bath sonicator for 5 minutes, then incubate statically for 60 minutes.

- ATP Measurement:

- Following incubation, pipette-mix the lysate 10 times without disturbing the material.

- Transfer 100 µL of the supernatant to a fresh well.

- Inject 100 µL of reconstituted luciferin/luciferase reagent (per manufacturer's instructions).

- Measure luminescence immediately using a plate reader with 1-second integration.

Protocol 3: Standard Curve Generation and Data Normalization

Objective: Correct for matrix effects to obtain accurate cell numbers.

- Generate a 3D-Specific Standard Curve: Seed constructs with a serial dilution of known cell numbers (e.g., 1,000 to 500,000 cells). After 24h, perform Protocol 2. Plot luminescence (RLU) vs. cell number.

- Calculate a Correction Factor (CF):

CF = (RLU from known cells in 3D) / (RLU from same cells lysed in 2D). - Normalize Unknown Samples:

Corrected RLU = Measured RLU / CF. Determine cell number from the 3D-specific standard curve.

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for ATP Assays in 3D Biomaterials

| Item | Function in 3D Context | Example/Notes |

|---|---|---|

| ATP Bioluminescence Assay Kit | Core detection chemistry. | Use kits with enhanced stability (e.g., CellTiter-Glo 3D). |

| Detergent-based Lysis Buffer | Disrupts cell and possibly matrix integrity for ATP release. | 1-2% Triton X-100 or NP-40; may require matrix-specific enzymes. |

| Recombinant Luciferase Enzyme | Catalyzes the light-producing reaction. | High-specific-activity grade reduces background in complex matrices. |

| D-Luciferin Substrate | Photon-emitting reaction substrate. | Ensure concentration is non-limiting in diffusion-limited systems. |

| Synthetic ATP Standard | For in-situ standard curves and recovery validation. | Prepare in matching lysis buffer to account for matrix effects. |

| Porous Scaffold Materials (e.g., PCL, PLGA) | 3D cell culture substrate. | Pre-sterilized, characterized pore size (150-300µm ideal). |

| Hydrogel Precursors (e.g., Alginate, PEGDA) | Form tunable 3D networks. | Degree of functionalization controls crosslinking density. |

| Penetration Enhancers (e.g., DMSO) | Optional additive to improve reagent diffusion. | Use at low concentrations (<0.5%) to avoid cell toxicity. |

Visualized Workflows and Pathways

Workflow for ATP Viability Assay in 3D Biomaterials

Key Barriers in 3D ATP Assay Signal Generation

In biomaterial cell viability research, particularly when utilizing ATP detection assays, robust data normalization is paramount. ATP concentration correlates with metabolically active cell number, but results can be confounded by variable cell seeding, biomaterial interaction, and extraction efficiency. Normalization to a stable intrinsic cellular property—total protein content, total DNA amount, or total cell number—is essential for accurate, comparable viability data. This application note details protocols and considerations for these three core strategies within the context of ATP-based biomaterial testing.

Comparative Analysis of Normalization Strategies

Table 1: Comparison of Data Normalization Strategies for ATP Assays in Biomaterial Studies

| Strategy | Measured Parameter | Primary Advantage | Key Limitation | Best Suited For |

|---|---|---|---|---|

| Protein Content | Total cellular protein (e.g., via BCA, Bradford) | Measures total biomass; common lab protocols. | Protein content per cell can vary with metabolic state and biomaterial interactions. | 2D cultures, scaffolds with high cell adhesion, when metabolic activity is stable. |

| DNA Content | Total double-stranded DNA (e.g., via fluorescent dyes) | Stable per nucleus; independent of metabolic state. | Does not account for cell size or cytoplasmic volume; can be affected by cell cycle. | 3D scaffolds, co-cultures, long-term studies where differentiation may occur. |

| Total Cell Number | Nuclei count (via imaging or counters) | Direct physical count; intuitive. | Requires cell lysis/detachment from biomaterial; may count non-viable cells. | Biomaterials where cells are easily released (e.g., non-adhesive hydrogels). |

Detailed Experimental Protocols

Protocol 3.1: ATP Assay with Concomitant Normalization (General Workflow)

This protocol outlines a parallel processing approach for ATP measurement and normalization.

Materials:

- Test biomaterial samples with cells.

- ATP detection kit (e.g., luminescence-based).

- Reagents for chosen normalization method (see Section 4).

- Multi-well plate reader capable of luminescence, absorbance, and fluorescence.

- Cell lysis reagent (compatible with both ATP and normalization assays).

Procedure:

- Sample Preparation: Seed cells on biomaterials in a multi-well plate. Incubate for desired period.

- Lysate Generation: a. Prepare ATP lysis buffer as per kit instructions. b. Aspirate culture medium from each well. c. Add appropriate volume of lysis buffer to each well. Shake gently for 5 minutes. d. Transfer the lysate to two separate microtubes: one for the ATP assay (Tube A) and one for the normalization assay (Tube B).

- ATP Measurement: a. Follow manufacturer's protocol for the ATP assay kit using Tube A lysates. b. Measure luminescence in a plate reader.

- Normalization Measurement: a. Proceed with the chosen normalization assay (Protocols 3.2, 3.3, or 3.4) using Tube B lysates.

- Calculation:

- Normalized ATP = (Raw ATP Luminescence) / (Normalization Value)

- Report as RLU/µg protein, RLU/ng DNA, or RLU/cell.

Protocol 3.2: Normalization to Total Protein Content (BCA Assay)

Materials: BCA Protein Assay Kit, bovine serum albumin (BSA) standards, microplate. Procedure:

- Prepare a series of BSA standards (0-2000 µg/mL) in the same lysis buffer as samples.

- Pipette 10 µL of each standard and unknown sample (from Tube B) into a microplate in duplicate.

- Add 200 µL of working BCA reagent to each well. Mix thoroughly.

- Cover plate, incubate at 37°C for 30 minutes.

- Cool to room temperature. Measure absorbance at 562 nm.

- Generate a standard curve (Abs562 vs. µg/mL BSA) and interpolate protein concentration for samples.

Protocol 3.3: Normalization to Total DNA Content (PicoGreen Assay)

Materials: Quant-iT PicoGreen dsDNA Assay Kit, lambda DNA standard, black-walled microplate. Procedure:

- Prepare DNA standards (0-1000 ng/mL) in TE buffer containing the same lysis buffer concentration as samples.

- Dilute sample lysates (Tube B) as necessary in TE buffer.

- Combine 100 µL of each standard/sample with 100 µL of diluted PicoGreen reagent in a black-walled plate.

- Incubate at room temperature, protected from light, for 5 minutes.

- Measure fluorescence (excitation ~480 nm, emission ~520 nm).

- Generate a standard curve and interpolate DNA concentration for samples.

Protocol 4.4: Normalization to Total Cell Number (Nuclei Counting via DAPI)

This protocol estimates cell number from lysates. Materials: DAPI (4',6-diamidino-2-phenylindole) stock solution, cell lysates (Tube B), fluorescence microplate or counter. Procedure:

- Prepare a standard curve using cells of known count, lysed identically to samples.

- Dilute DAPI stock to working concentration (e.g., 1 µg/mL) in a suitable buffer (e.g., PBS).

- Mix an aliquot of sample/standard lysate with an equal volume of DAPI working solution.

- Incubate for 5-10 minutes protected from light.

- Measure fluorescence (excitation ~358 nm, emission ~461 nm).

- Generate a standard curve (Fluorescence vs. Cell Number) and interpolate cell number for samples.

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions for ATP Assay Normalization

| Item | Function | Example Product/Kit |

|---|---|---|

| ATP Detection Kit | Quantifies ATP via luciferase reaction, producing luminescent signal proportional to viable cell number. | CellTiter-Glo 3D, ViaLight Plus |

| BCA Protein Assay Kit | Colorimetric detection of total protein based on bicinchoninic acid reaction for normalization. | Pierce BCA Protein Assay Kit |

| PicoGreen dsDNA Assay Kit | Ultrasensitive fluorescent quantification of double-stranded DNA for normalization. | Quant-iT PicoGreen dsDNA Assay |

| DAPI Stain | Fluorescent DNA dye for nuclei counting in lysates or fixed samples. | Dihydrochloride (DAPI) |

| Universal Lysis Buffer | A buffer compatible with simultaneous extraction of ATP, protein, and DNA. Often contains detergents and buffers. | Passive Lysis Buffer (PLB) |

| Microplate Reader | Instrument capable of reading luminescence (ATP), absorbance (BCA), and fluorescence (PicoGreen, DAPI). | SpectraMax i3x, CLARIOstar |

Visualizing Workflows and Relationships

Title: Biomaterial Cell Viability Assay Workflow with Normalization

Title: Logical Rationale for Data Normalization in Viability Assays

Solving Common Problems: Troubleshooting ATP Assay Pitfalls with Biomaterials

Within biomaterial cell viability research, ATP detection assays are a cornerstone for quantifying metabolically active cells. A frequent and critical challenge is obtaining a lower-than-expected luminescent signal, which can lead to inaccurate viability underestimation. This application note systematically addresses the three primary culprits: Incomplete Cell Lysis, ATP Degradation, and Signal Quenching. Accurate diagnosis and resolution are essential for validating the biocompatibility of novel drug delivery scaffolds, tissue engineering constructs, and other biomaterials.

Core Problem Diagnosis: A Systematic Approach

A low luminescence signal (RLU - Relative Light Units) can stem from distinct issues. The following flowchart guides the troubleshooting process.

Diagram 1: Diagnostic flowchart for low ATP signal.

Incomplete Cell Lysis

Incomplete lysis fails to release the intracellular ATP pool, causing artificially low readings. This is common with robust primary cells or cells within dense 3D biomaterial scaffolds.

Protocol: Lysate Spike-In Recovery Test

This test differentiates between lysis inefficiency and other issues.

Materials:

- Test cell lysate (potentially incomplete)

- Fully lysed control cell sample (e.g., using a validated detergent like 1% Triton X-100)

- ATP assay reagent

- ATP standard

- Luminometer-compatible plate.

Method:

- Prepare two identical samples of cells on the biomaterial.

- Lyse Sample A with the standard assay lysis buffer. This is the Test Lysate.

- Lyse Sample B with a powerful, validated lysis buffer (e.g., 1% Triton X-100, freeze-thaw cycles). This is the Complete Lysate Control.

- Serially dilute a pure ATP standard in both the Test Lysate and a buffer-only control.

- Perform the ATP assay on both dilution series.

- Compare the recovered ATP concentration from the Test Lysate spike-in series to the buffer-only series. Calculate % Recovery.

Interpretation: Recovery <90% in the test lysate matrix suggests incomplete lysis or the presence of quenching agents. Compare the total ATP in Sample A vs. Sample B; a significant difference indicates incomplete lysis.

Data Table: Example Spike-In Recovery

| ATP Spike Concentration (nM) | RLU in Buffer (Mean ± SD) | RLU in Test Lysate (Mean ± SD) | % Recovery |

|---|---|---|---|

| 0 | 150 ± 25 | 520 ± 45 | - |

| 10 | 2250 ± 210 | 1980 ± 190 | 88% |

| 100 | 20,500 ± 1750 | 16,800 ± 1520 | 82% |

Solution: Optimize lysis by increasing detergent concentration, adding mechanical disruption (sonication), or extending incubation time, especially for 3D scaffolds.

ATP Degradation

ATP is labile and can be degraded by ATPases (e.g., ecto-ATPases on cell membranes) or adverse storage conditions, leading to signal loss.

Protocol: Kinetic Signal Stability Test

Assesses the rate of signal decay after lysis, indicating active degradation.

Method:

- Lyse a sample and immediately add ATP assay reagent.

- Measure luminescence (RLU) immediately (t=0) and at regular intervals (e.g., 1, 2, 5, 10, 20 min) without shaking.

- Plot RLU vs. Time.

Interpretation: A rapid, steady decline suggests ATP degradation. A stable signal for several minutes followed by a slow decline is typical of assay reagent consumption.

Data Table: Kinetic Signal Stability

| Time Post-Reagent Addition (min) | RLU (Mean ± SD) | % Initial Signal |

|---|---|---|

| 0 | 50,000 ± 3,200 | 100% |

| 2 | 48,500 ± 2,950 | 97% |

| 5 | 45,200 ± 3,100 | 90% |

| 10 | 38,000 ± 2,850 | 76% |

| 20 | 25,500 ± 2,200 | 51% |

Solution:

- Inhibit ATPases: Include ATPase inhibitors (e.g., sodium azide, apyrase inhibitors) in the lysis buffer.

- Work Quickly: Process samples on ice and read plates immediately after reagent addition.

- Use Stabilized Reagents: Employ commercial kits with optimized, stabilized luciferase formulations.

Signal Quenching

Certain biomaterial components (e.g., colored polymers, metallics, ceramics) or cell culture media additives can absorb light or inhibit the luciferase enzyme, reducing detected RLU.

Protocol: Standard Curve in Sample Matrix Test

The definitive test for optical or chemical quenching.

Method:

- Generate a standard ATP dilution series in a clear, inert buffer (Control Curve).

- Generate an identical ATP dilution series in the presence of a non-viable, lysed aliquot of the biomaterial sample or its extract (Matrix Curve).

- Perform the ATP assay on both curves.

- Compare slopes and linear ranges.

Interpretation: A parallel curve with a lower slope indicates optical quenching (light absorption). A non-parallel curve with reduced slope and linear range indicates chemical quenching/inhibition (enzyme interference).

Diagram 2: Standard curve patterns indicating quenching.

Solution:

- Optical Quenching: Use a white-walled plate, ensure biomaterial is at the bottom of the well, or use an internal standard.

- Chemical Quenching: Dilute the lysate, modify biomaterial processing, or use a kit with a robust luciferase mutant resistant to inhibitors.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item & Example | Function in ATP Assay Troubleshooting |

|---|---|

| Powerful Lysis Buffer (e.g., with 1% Triton X-100, 0.5% SDS) | Positive control for complete cell membrane disruption; validates lysis efficiency. |

| ATPase Inhibitors (e.g., Sodium Azide, NaF) | Preserves ATP post-lysis by inhibiting enzymatic degradation. |

| Stabilized Luciferase/Luciferin Reagent (Commercial ATP kits) | Provides consistent, prolonged light output; less prone to quenching. |

| Pure ATP Standard | Essential for generating calibration curves and performing spike-in recovery tests. |

| White-Opaque Multiwell Plates | Minimizes light cross-talk and loss; critical for low-signal or quenching samples. |

| Non-Quenching, Compatible Solvents (e.g., DMSO tested for assay interference) | For solubilizing drugs or biomaterial extracts without inhibiting luciferase. |

1. Introduction In the context of a broader thesis on ATP detection assays for biomaterial cell viability research, high background noise from auto-luminescence and material interference represents a critical, yet often underestimated, confounder. Accurate quantification of cellular ATP is paramount for assessing the biocompatibility and functionality of novel biomaterials in drug development and regenerative medicine. This application note details the sources of this interference and provides validated protocols for its identification, quantification, and mitigation to ensure assay fidelity.

2. Sources of Interference & Quantitative Impact Background noise in luminescent ATP assays arises from two primary sources: intrinsic material properties and assay reagent interactions. The following table summarizes key interferents and their typical impact on background Relative Light Units (RLU).

Table 1: Common Sources of Background Noise in Biomaterial ATP Assays

| Interference Source | Example Materials/Compounds | Mechanism | Typical RLU Increase (vs. Blank) | Effect on Viability Readout |

|---|---|---|---|---|

| Auto-luminescence | Certain polymers (e.g., some polyurethanes), ceramics, degradation by-products (e.g., H₂O₂, aldehydes). | Direct photon emission without luciferase. | 200 - 5000 RLU (material-dependent) | False elevation of apparent viable cell count. |

| Quenching | High pigment materials (e.g., melanin, certain dyes), carbon-based nanomaterials (e.g., some graphene oxides). | Absorption of emitted luminescence. | Reduction of 20-60% in signal. | Underestimation of viable cell count. |

| Luciferase Inhibition | Heavy metals (e.g., Zn²⁺, Cu²⁺ leached from alloys), phenolic compounds from polymers. | Direct enzyme inhibition or ATP hydrolysis. | Suppression of 30-80% in signal. | Severe underestimation of viability. |

| ATP Contamination | Animal-derived scaffold components (e.g., collagen, silk fibroin) with residual cellular ATP. | Introduction of exogenous ATP. | 100 - 2000 RLU (batch-dependent) | False positive viability signal. |

| Solution Turbidity | Particulate leaching, insoluble degradation products. | Light scattering. | Variable increase or decrease in RLU. | Increased signal variability and error. |

3. Core Diagnostic Protocol: Establishing the Background Profile of a Biomaterial This protocol must be performed prior to any cell-based experiment to establish a material's inherent interference profile.

- Objective: To quantify the auto-luminescence and ATP-contamination of a test biomaterial.

- Materials:

- Test biomaterial (sterilized, in triplicate samples).

- Appropriate cell culture medium (without phenol red).

- ATP assay kit (luciferin-luciferase based).

- White-walled, opaque 96-well assay plates.

- Luminometer.

- Procedure:

- Sample Preparation: Cut/place biomaterial to fit well bottom. For 3D scaffolds, use consistent mass/volume.

- Pre-incubation: Add 100 µL of culture medium to each material sample and control wells (medium only). Incubate plate at 37°C for 24h to simulate leaching.

- Background Measurement (Step A - Auto-luminescence): Directly measure luminescence from all wells (integration time: 1s). Record as Auto-luminescence RLU.

- Reagent Addition: Add 100 µL of reconstituted ATP assay reagent (containing lysis agent) to each well. Mix thoroughly on an orbital shaker for 5 minutes.

- Total Signal Measurement (Step B): Measure luminescence immediately. Record as Total RLU.

- Data Analysis:

- Auto-luminescence = RLU from Step A (Material) - RLU from Step A (Medium Control).

- ATP Contamination = RLU from Step B (Material) - RLU from Step B (Medium Control) - Auto-luminescence.

- Interpretation: A significant Auto-luminescence value necessitates signal correction protocols. A significant ATP Contamination value mandates rigorous pre-washing of the material before cell seeding.

4. Mitigation Protocol: Signal Correction via Parallel Lysis Control When auto-luminescence is confirmed, this protocol enables its subtraction from experimental cell-seeded samples.

- Objective: To obtain corrected ATP values from cells cultured on interfering biomaterials.

- Experimental Design: For each test condition (material + cell type), include a parallel set of Cell-Free Material Controls.

- Procedure:

- Plate cells on biomaterials in the experimental plate. In a parallel control plate, prepare identical material samples without cells.

- Culture for the desired period.

- At assay time, for the experimental plate, add ATP assay reagent, lyse, and measure. This yields Raw Experimental RLU.

- For the cell-free control plate, add ATP assay reagent identically and measure simultaneously. This yields Background RLU (Material + Reagent).

- Calculation: Corrected ATP RLU = Raw Experimental RLU - Background RLU (Material + Reagent).

- Convert Corrected ATP RLU to ATP concentration using a standard curve generated in the presence of cell-free material extract to account for any quenching.

5. The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for High-Fidelity ATP Assays on Biomaterials

| Item | Function & Rationale |

|---|---|

| Phenol Red-Free Medium | Eliminates optical interference (absorbance/quenching) from the pH indicator during luminescence reading. |

| Opaque White-Well Plates | Maximizes light signal capture and prevents cross-talk between wells, critical for low-light signals. |

| Recombinant (Non-Animal Derived) Luciferase | Reduces risk of background ATP contamination that can be present in firefly tail-extracted enzyme preparations. |