Beyond Plastic: The Tiny Crystals Powering Tomorrow's Medical Miracles

How X-Ray Diffraction unlocks the potential of biodegradable mcl-PHA nanocomposites

Introduction

Imagine a world where surgical implants dissolve safely after healing, where drug delivery systems release medicine with pinpoint timing, and where tissue scaffolds guide your body's own repair – all made from materials that vanish like sugar in water. This isn't science fiction; it's the promise of biodegradable polymers.

Among the frontrunners are Medium Chain Length Polyhydroxyalkanoates (mcl-PHAs), nature's own plastics, produced by bacteria. But to make them truly shine in demanding biomedical roles, scientists are supercharging them, creating mcl-PHA-based nanocomposites. And the secret weapon to understanding and perfecting these wonder materials? X-Ray Diffraction (XRD).

Nature's Plastic Factory

Bacteria storing energy as PHA granules under stress conditions.

The Building Blocks: mcl-PHAs and Nanocomposites

Nature's Plastic Factory: mcl-PHAs

Picture bacteria under stress, storing energy not as fat, but as tiny plastic granules inside their cells. These granules are PHAs. "Medium Chain Length" refers to the size of the molecular building blocks (typically 6-14 carbon atoms long). This gives mcl-PHAs fantastic properties for medicine:

- Biocompatible: Your body generally accepts them without severe reactions.

- Biodegradable: They break down naturally into harmless substances.

- Tunable: Scientists can tweak their flexibility, strength, and degradation rate.

- Processable: They can be molded into films, fibers, or 3D-printed structures.

Supercharging with Nanotechnology

While mcl-PHAs are great, they sometimes need a boost – better strength, slower degradation, controlled drug release, or even added functions like electrical conductivity or antimicrobial properties. This is where nanocomposites come in.

The Crystal Detective: X-Ray Diffraction (XRD)

XRD is crucial for nanocomposites because it reveals:

- Crystallinity: How much of the polymer is ordered (crystalline) vs. disordered (amorphous)?

- Crystal Structure: What specific arrangement do the polymer chains take?

- Nanoparticle Dispersion: Are the nanoparticles clumped together or spread out?

- Interactions: Are the nanoparticles altering how polymer chains pack into crystals?

- Nanoparticle Identity: Confirming the type and crystalline nature of nanoparticles.

Think of XRD like this:

- X-rays are beamed at the material.

- The atoms within the material cause the X-rays to scatter.

- If the atoms are arranged in a regular, repeating pattern (crystals), they scatter the X-rays at very specific angles.

- The pattern of these scattered X-rays (the diffraction pattern) is like a fingerprint unique to the crystal structure.

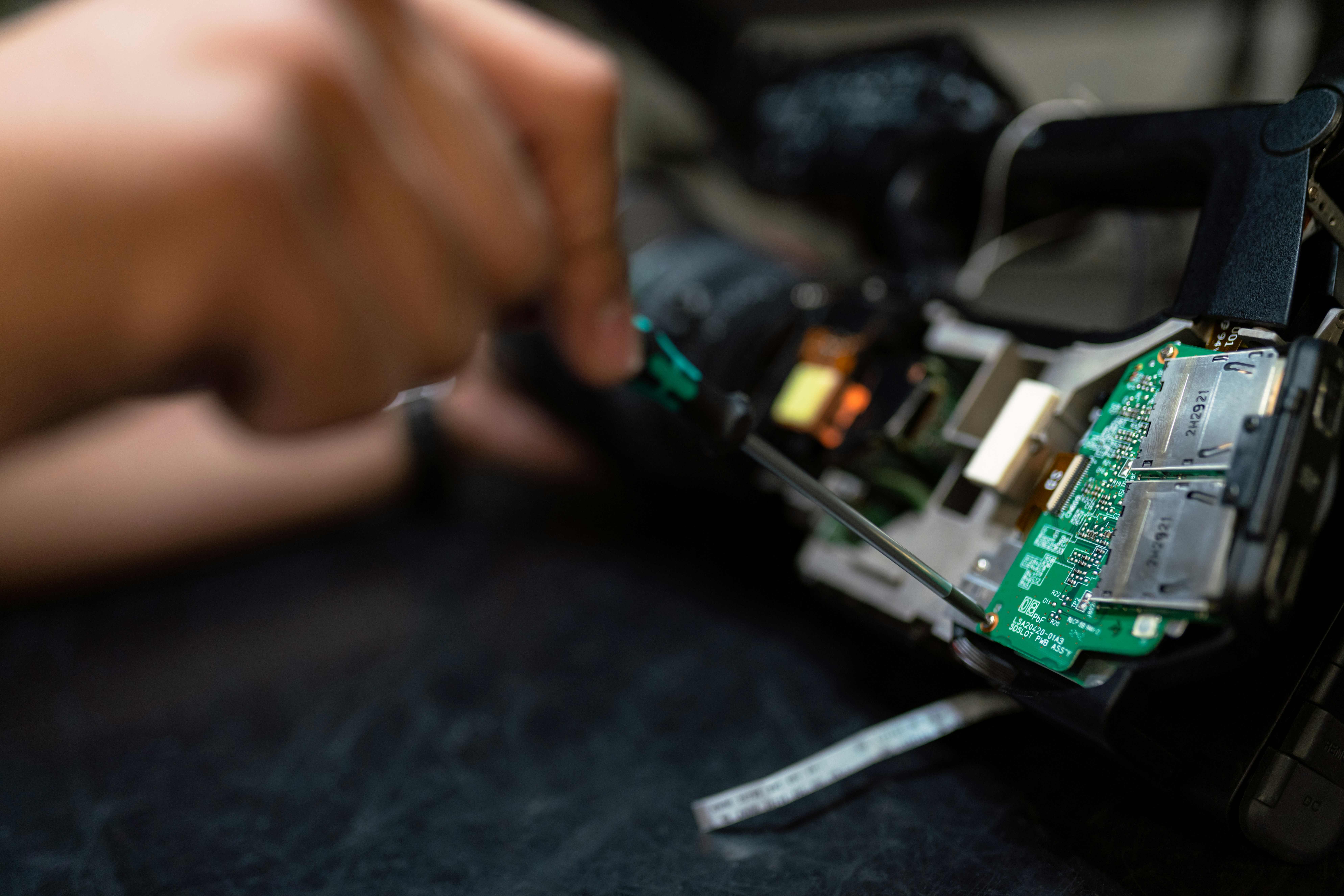

X-Ray Diffractometer

Modern XRD equipment used to analyze crystal structures of materials.

Bragg's Law (nλ = 2d sinθ) is fundamental to XRD analysis

The Experiment: Probing Nanoclay Reinforcement with XRD

Hypothesis

Incorporating organically modified montmorillonite (OMMT) nanoclay into an mcl-PHA (e.g., poly(3-hydroxyoctanoate-co-3-hydroxydecanoate), PHOD) will improve its mechanical properties and thermal stability by enhancing polymer crystallinity and providing effective reinforcement, as revealed by changes in XRD patterns.

Methodology: Step-by-Step

- Obtain purified mcl-PHA (e.g., PHOD) granules.

- Obtain organically modified montmorillonite (OMMT) nanoclay powder.

- Prepare solvent (e.g., chloroform) for solution casting.

- Solution Prep: Dissolve PHOD granules completely in chloroform.

- Nanoclay Dispersion: Suspend OMMT in chloroform and ultrasonicate for 30-60 minutes.

- Mixing: Add nanoclay dispersion to polymer solution under vigorous stirring.

- Casting: Pour mixture onto clean glass Petri dish.

- Solvent Evaporation: Allow chloroform to evaporate slowly.

- Mount samples on XRD holder.

- Set X-ray source (Copper K-alpha radiation, λ ≈ 1.54 Å).

- Set scan range (2θ = 2° to 40°).

- Set scan speed (2° per minute) and step size (0.02°).

- Start scan and record diffraction patterns.

Essential Research Reagents

- mcl-PHA (PHOD) Core

- OMMT Nanoclay Filler

- Chloroform Solvent

- Ultrasonic Probe Dispersion

- XRD Equipment Analysis

Results and Analysis: Decoding the Patterns

XRD Diffractograms

The XRD instrument outputs a graph (diffractogram) for each sample: X-axis is the diffraction angle (2θ), Y-axis is the intensity (counts).

- Pure PHOD: Shows characteristic peaks indicating its semi-crystalline nature.

- Pure OMMT Nanoclay: Shows a prominent, sharp peak at a low angle (e.g., 2θ ≈ 3.5°-4.5°).

- Nanocomposites: The OMMT (001) peak shifts to a lower angle, indicating intercalation.

What the Shift Means

Using Bragg's Law (nλ = 2d sinθ), a decrease in 2θ means an increase in the d-spacing (d). This is intercalation. PHOD polymer chains have penetrated the spaces between the clay layers, pushing them further apart. This is a sign of good compatibility and dispersion!

Table 1: XRD Peak Analysis of PHOD/OMMT Nanocomposites

| Sample | OMMT (001) Peak Position (2θ) | Calculated d-Spacing (nm) | Interpretation |

|---|---|---|---|

| Pure OMMT | ~4.0° | ~2.2 nm | Baseline spacing |

| PHOD + 1% OMMT | ~3.2° | ~2.8 nm | Intercalation |

| PHOD + 3% OMMT | ~2.8° | ~3.2 nm | Strong Intercalation |

| PHOD + 5% OMMT | Very Broad / ~2.5° | ~3.5 nm / N/A | Partial Exfoliation |

Table 2: Linking XRD Findings to Key Biomedical Material Properties

| XRD Observation | Material Property Impact | Biomedical Significance |

|---|---|---|

| Nanoclay Intercalation | Increased Tensile Strength & Modulus | Stronger bone plates, sutures, stents |

| Nanoclay Exfoliation | Maximum Reinforcement Efficiency | Optimized strength with minimal filler |

| Increased Polymer Crystallinity | Higher Stiffness, Slower Degradation | Predictable implant lifespan |

| Good Nanoparticle Dispersion | Uniform Properties, Reduced Defects | Reliable implant performance |

Impact of Nanoclay Loading on Properties

Why This Matters for Biomedicine

The XRD results tell a story crucial for performance:

- Reinforcement Confirmed: Intercalation/exfoliation means the nanoclay is effectively dispersed and interacting with the polymer.

- Enhanced Crystallinity: Increased PHOD peak intensity suggests the nanoclay acts as a nucleating agent.

- Predicting Performance: By linking XRD data to mechanical tests, scientists can design better nanocomposites.

Conclusion: A Crystal Clear Path Forward

The journey of mcl-PHA nanocomposites from bacterial factories to life-saving medical devices is complex, but X-Ray Diffraction provides an indispensable map. By revealing the hidden crystalline architecture – the degree of polymer order, the intimate dance between polymer chains and nanoparticles, and the state of nanoparticle dispersion – XRD allows scientists to understand why a nanocomposite behaves the way it does.

This knowledge is power. It enables the rational design of stronger, more durable, and smarter biodegradable materials: bone implants that support healing and then vanish, drug capsules that release their payload with exquisite timing, or nerve guides that perfectly bridge damaged tissues.

Future Medical Applications

Potential uses of mcl-PHA nanocomposites in medicine.

- Bone implants

- Drug delivery

- Tissue scaffolds

Note: The specific experiment described, while based on common methodologies and realistic outcomes reported in the scientific literature, is a composite illustration designed to clearly demonstrate the principles of XRD evaluation in this field. Actual experimental details vary significantly across studies.