Poly(2-Hydroxyethyl Methacrylate) Hydrogels: From Foundational Material to Advanced Drug-Eluting Contact Lens Applications

This comprehensive review explores the enduring role of poly(2-hydroxyethyl methacrylate) (PHEMA) hydrogels in contact lens applications, with a specific focus on the evolving frontier of ophthalmic drug delivery.

Poly(2-Hydroxyethyl Methacrylate) Hydrogels: From Foundational Material to Advanced Drug-Eluting Contact Lens Applications

Abstract

This comprehensive review explores the enduring role of poly(2-hydroxyethyl methacrylate) (PHEMA) hydrogels in contact lens applications, with a specific focus on the evolving frontier of ophthalmic drug delivery. It covers the foundational chemistry and intrinsic properties of PHEMA that established it as a benchmark material. The article details advanced methodological approaches for fabricating and functionalizing PHEMA-based lenses, including the integration of natural biomaterials to overcome inherent limitations in drug loading and release kinetics. A critical analysis addresses key challenges such as low oxygen permeability and uncontrolled drug release, presenting optimization strategies like copolymerization and surface modifications. Finally, the review provides a comparative validation of PHEMA against modern silicone hydrogels and emerging natural biomaterials, contextualizing its unique value proposition for researchers and drug development professionals working on therapeutic ophthalmic devices.

The PHEMA Foundation: Chemistry, Properties, and Historical Significance in Contact Lenses

Chemical Structure and Fundamental Properties of PHEMA Hydrogels

Poly(2-hydroxyethyl methacrylate), or pHEMA, is a foundational synthetic polymer that revolutionized eye care with the development of the first soft corneal contact lens [1]. Its unique molecular structure, comprising a hydrophobic carbon backbone with hydrophilic hydroxyl-functionalized side chains, enables the formation of hydrogels—three-dimensional, cross-linked networks capable of absorbing significant amounts of water while maintaining structural integrity [2]. This balance of properties, including biocompatibility, optical clarity, and mechanical stability, has established pHEMA as a dominant material in the traditional contact lens market and a critical component in biomedical research [3] [2]. Within the context of contact lens applications, ongoing research focuses on enhancing pHEMA's inherent characteristics, such as improving surface wettability, mechanical strength, and functionality for sustained drug delivery, to address limitations like dry eye syndrome and protein deposition [1]. This document outlines the fundamental properties and provides detailed experimental protocols for the synthesis and characterization of pHEMA-based hydrogels, serving as a guide for researchers and scientists in the field.

Fundamental Properties and Performance Data

The performance of pHEMA hydrogels in contact lens applications is governed by a set of key physicochemical properties. These include water content, which influences comfort and oxygen permeability; mechanical properties, which affect durability and handling; and optical transparency, which is critical for vision. The following tables summarize quantitative data for these properties across different pHEMA-based formulations, providing a basis for comparison and material selection.

Table 1: Physicochemical Properties of pHEMA Hydrogels with Different Crosslinkers

| Crosslinking Agent | Equilibrium Water Content (EWC%) | Tensile Stress (MPa) | Young's Modulus (MPa) | Onset Decomposition Temperature (°C) | Citation |

|---|---|---|---|---|---|

| TEGDA (Triethylene glycol dimethacrylate) | ~31% | Highest value reported | Best at low water content | 280 | [4] |

| HDODA (1,6-hexanediol diacrylate) | ~37% | - | - | 275 | [4] |

| EGDMA (Ethylene glycol dimethacrylate) | - | - | - | ~190 | [4] |

| mHA-β-CD (Methacrylated hyaluronan-β-cyclodextrin) | ~60% | Good mechanical properties reported | - | - | [1] |

| Standard pHEMA (Reference) | ~30% | - | - | - | [1] |

Table 2: Functional Performance of Modified pHEMA Hydrogels

| Hydrogel Material | Key Functional Property | Performance Outcome | Citation |

|---|---|---|---|

| p(HEMA-co-mHA-β-CD) | Surface Hydrophilicity (Water Contact Angle) | Reduced to ~50°-60° vs. ~80° for standard pHEMA | [1] |

| p(HEMA-co-mHA-β-CD) | Tear Protein Deposition | Enhanced resistance to Bovine Serum Albumin (BSA) and Lysozyme | [1] |

| p(HEMA-co-mHA-β-CD) | Drug Release (Puerarin) | Sustained release over 90 hours; release kinetics fit to Korsmeyer-Peppas model | [1] |

| pHEMA-gr-PVP | Surface Hardness & Heat Resistance | Increased with higher PVP content in initial composition | [5] |

| pHEMA-gr-PVP | Elasticity (Swollen State) | Increased with higher PVP content | [5] |

Experimental Protocols

Protocol 1: Synthesis of p(HEMA-co-mHA-β-CD) Hydrogel

This protocol describes the synthesis of an advanced pHEMA copolymer using methacrylated hyaluronic acid functionalized with β-cyclodextrin (mHA-β-CD) as a macromolecular crosslinker. This formulation aims to enhance hydrophilicity, mechanical strength, and sustained drug delivery capability [1].

- Objective: To synthesize a pHEMA-based copolymer hydrogel with high water content, good mechanical properties, and sustained drug release functionality.

- Principle: The rigid, hydrophilic mHA-β-CD macromer acts as a functional crosslinker, copolymerizing with HEMA monomers via free radical polymerization to form a robust network. β-cyclodextrin's ability to form inclusion complexes with drug molecules enables sustained release [1].

Experimental Workflow: Synthesis of p(HEMA-co-mHA-β-CD) Hydrogel

Materials:

- HEMA (2-hydroxyethyl methacrylate): Primary monomer. Must be purified and distilled under vacuum before use to remove inhibitors [1] [5].

- mHA-β-CD (Methacrylated hyaluronan-β-cyclodextrin): Functional macromolecular crosslinker. Synthesized in a multi-step process prior to hydrogel synthesis [1].

- APS (Ammonium Persulfate): Initiator for free radical polymerization [1].

- Deionized Water: Solvent for polymerization and hydration.

Procedure:

- Monomer Solution Preparation: Dissolve the synthesized mHA-β-CD macromer in HEMA monomer. The ratio of mHA-β-CD to HEMA determines the final crosslinking density and properties [1].

- Initiation: Add ammonium persulfate (APS) to the monomer solution to initiate the polymerization reaction.

- Polymerization: Pour the solution into a suitable mold (e.g., a contact lens mold) and allow the free radical polymerization to proceed to completion, forming a solid polymer network.

- Post-processing: Remove the synthesized hydrogel from the mold and hydrate it in deionized water or a buffered saline solution. Rinse extensively to remove any unreacted monomers, initiator, or soluble oligomers [1] [5].

Characterization Methods:

- Nuclear Magnetic Resonance (NMR): Verify the chemical structure and composition of the mHA-β-CD derivative and the final copolymer [1].

- Equilibrium Water Content (EWC): Measure the water absorption capacity using the formula:

EWC% = [(W_s - W_d) / W_s] * 100, where Ws is the swollen hydrogel weight and Wd is the dry hydrogel weight [1] [4]. - Water Contact Angle: Assess surface wettability using a goniometer. A lower angle indicates higher hydrophilicity [1].

- Tensile Testing: Determine mechanical properties (tensile strength, elongation at break) using a universal testing machine [1] [4].

- UV-Vis Spectroscopy: Evaluate optical transparency in the visible light range [1].

- Drug Release Kinetics: Conduct in vitro release studies using Franz diffusion cells or similar apparatus, with the release data often modeled using the Korsmeyer-Peppas equation [1] [6].

Protocol 2: Synthesis of pHEMA-gr-PVP Graft Copolymer Hydrogel

This protocol details the synthesis of a pHEMA hydrogel grafted with polyvinylpyrrolidone (PVP) using an iron(II) sulfate initiation system. This method produces macroporous hydrogels at room temperature and in the presence of air, simplifying the process [5].

- Objective: To synthesize a grafted pHEMA-PVP copolymer hydrogel with a macroporous structure and tunable sorption-mechanical properties.

- Principle: Polymerization of HEMA in the presence of PVP, initiated by Fe²⁺ ions, results in a grafted, cross-linked copolymer network. PVP acts as a pore-forming agent and modifies the hydration and mechanical characteristics of the resulting hydrogel [5].

Experimental Workflow: Synthesis of pHEMA-gr-PVP Hydrogel

Materials:

- HEMA (2-hydroxyethyl methacrylate): Primary monomer. Must be purified and distilled under vacuum [5].

- PVP (Polyvinylpyrrolidone), M_w ~28,000: Grafting polymer. Should be dried at 338 K in a vacuum before use.

- Iron(II) Sulfate (FeSO₄): Initiation catalyst.

- Deionized Water: For hydration and rinsing.

Procedure:

- Solution A (Fe²⁺): Dissolve 0.05% by weight of FeSO₄ in approximately one-third of the total required HEMA monomer.

- Solution B (PVP): Dissolve the desired amount of PVP (typically 10-40 parts per 100 parts HEMA) in the remaining two-thirds of HEMA.

- Mixing: Combine Solution A and Solution B to form a homogeneous mixture without insoluble agglomerates.

- Polymerization: Cast the mixture into a polymerization mold. The polymerization will proceed at room temperature, in air, over 0.3 to 1.5 hours, depending on the formulation.

- Hydration and Purification: Rinse the polymerized product extensively in distilled water to remove unreacted HEMA and, crucially, any PVP that was not grafted onto the polymer network [5].

Characterization Methods:

- Fourier-Transform Infrared Spectroscopy (FTIR): Confirm the formation of the graft copolymer and the presence of PVP [5].

- Scanning Electron Microscopy (SEM): Visualize the macroporous structure (pore sizes of 10–30 μm) [5].

- Thermogravimetric Analysis (TGA) / Differential Thermal Analysis (DTA): Evaluate thermal stability and decomposition profile [4] [5].

- Sorption-Diffusion Studies: Measure water uptake capacity and kinetics [5].

- Mechanical Testing: Assess tensile strength and elasticity of the swollen hydrogel [5].

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for pHEMA Hydrogel Research

| Reagent | Function / Role in Research | Key Consideration |

|---|---|---|

| HEMA Monomer | The primary building block for forming the polymer backbone. | Requires purification (distillation) to remove inhibitors like MEHQ for reproducible polymerization [5]. |

| EGDMA / TEGDA / HDODA | Small molecular crosslinkers that control the mesh size and density of the polymer network. | Type and concentration directly and significantly impact mechanical strength, water content, and transparency [1] [4]. |

| PVP (Polyvinylpyrrolidone) | A hydrophilic polymer used as a grafting agent to modify water content, elasticity, and surface properties. | The amount of PVP that is successfully grafted (vs. washed away) determines the final material properties [5]. |

| Methacrylated Hyaluronic Acid (mHA) | A rigid, hydrophilic macromer used as a co-monomer and crosslinker to enhance mechanical strength and hydrophilicity. | The degree of methacrylation controls its reactivity and integration into the pHEMA network [1]. |

| β-Cyclodextrin (β-CD) | A functional additive that provides host-guest interaction sites within the hydrogel, enabling sustained drug delivery. | Must be chemically bonded to the polymer network (e.g., via mHA) to prevent leaching and enable effective drug encapsulation [1]. |

| Ammonium Persulfate (APS) | A common thermal initiator for free radical polymerization reactions. | Concentration affects the polymerization rate and the molecular weight of the resulting polymer chains. |

| Iron(II) Sulfate (FeSO₄) | An initiation catalyst for room-temperature polymerization, particularly useful in graft copolymerization with PVP. | Allows for rapid polymerization in air, simplifying the process [5]. |

Structure-Property Relationships in pHEMA Hydrogels

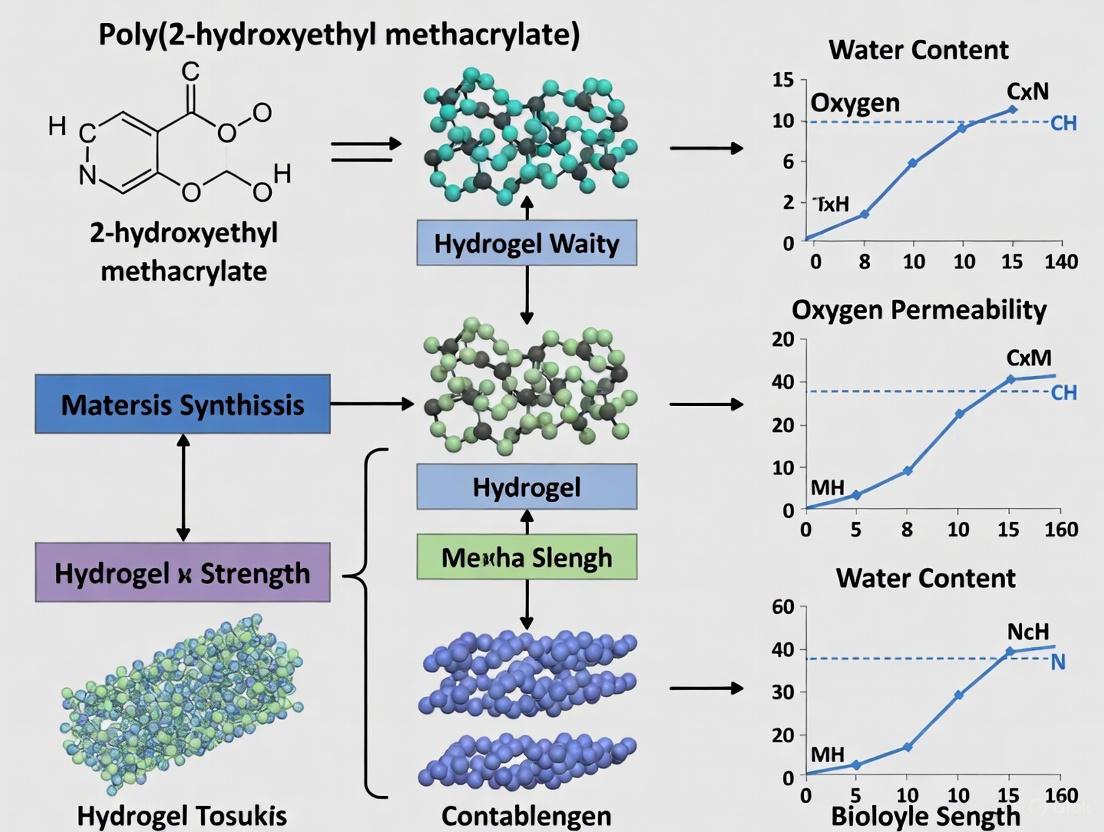

The properties of a pHEMA hydrogel are not intrinsic but are directly engineered through its chemical composition and synthesis conditions. The following diagram illustrates the logical relationship between key structural modifications and the resulting physicochemical properties.

Structure-Property Relationships in Modified pHEMA Hydrogels

Historical Context and Scientific Breakthrough

The invention of soft contact lenses represents a convergence of material science and biomedical engineering, pioneered by the Czech chemist Otto Wichterle. Born in 1913, Wichterle preferred a life in science over a career in his family's business [7]. His research trajectory changed during a train ride in 1952, where a conversation with an official from the Ministry of Health sparked his interest in biological plastics [7]. This encounter initiated Wichterle's lifelong journey into hydrogel development.

By 1952, Wichterle and his colleague Drahoslav Lím began intensive research on biocompatible plastics [8]. Within just six months, they successfully synthesized a hydrophilic gel known as poly(2-hydroxyethyl methacrylate) or pHEMA [7] [9]. This material exhibited unique properties ideal for biological applications: it was flexible, oxygen permeable, and optically clear [7]. The researchers recognized that pHEMA's capacity to absorb up to 40% water while maintaining suitable mechanical properties and transparency made it potentially suitable for ocular applications [8].

Despite this promising discovery, Wichterle faced significant institutional challenges. The Ministry of Health in Czechoslovakia rejected his proposal for developing contact lenses from pHEMA [7]. Political purges led to his removal from the Institute of Chemical Technology in 1958, forcing him to continue research domestically [7] [8]. By 1961, with budget cuts ceasing hydrogel investigations at the Institute of Macromolecular Chemistry, Wichterle was forced to resolve lens production issues at his home [7].

The pivotal breakthrough occurred in late 1961 when Wichterle succeeded in producing the first four hydrogel contact lenses on a home-made apparatus built using a children's building kit (Merkur), a bicycle dynamo, and a bell transformer [8]. On Christmas afternoon, with his wife Linda's assistance, he produced lenses using a centrifugal casting procedure on his kitchen table [8]. Although these initial lenses had incorrect optical power, they demonstrated exceptional comfort, validating pHEMA's suitability for ocular use [8].

Fundamental Properties of pHEMA Hydrogels

pHEMA belongs to a class of synthetic hydrogels characterized by highly hydrophilic polymeric networks. The material's molecular structure enables unique physicochemical properties that make it ideal for contact lens applications and other biomedical uses.

Physicochemical Characteristics

pHEMA is a biocompatible, non-biodegradable, and optically transparent hydrophilic polymer [9]. In its dry state, pHEMA exists as a hard and brittle material, but upon swelling with water or biological fluids, it becomes flexible and soft while maintaining optical clarity [9]. This transition occurs due to the hydrophilic pendant groups in its chemical structure that facilitate water absorption.

The typical glass transition temperature (Tg) of pHEMA ranges between 358–393 K, with a density of 1.15–1.34 g mL⁻¹ [9]. The polymer demonstrates resistance to crack propagation, leading to high load-bearing ability despite its hydrogel nature [9]. The mechanical (tensile strength and Young's modulus) and optical (light transmission) properties, oxygen permeability, and water absorption of pHEMA-based hydrogels can be modified through different polymerization techniques, copolymerization, and varying cross-linking rates [9].

pHEMA in Biomedical Applications

Beyond contact lenses, pHEMA's unique properties have enabled diverse biomedical applications:

- Bone Tissue Regeneration: pHEMA/hydroxyapatite biocomposites exhibit elastomeric properties but require degradable cross-linkers for practical application [9]

- Wound Healing: pHEMA-based dressings provide transparency and biocompatibility, though they have limitations in exudate absorbability [9]

- Drug Delivery Systems: pHEMA serves as a carrier for controlled drug release, with applications in cancer therapy and ocular drug delivery [9] [10]

- Blood-Contacting Devices: Recent research incorporates degradable cross-linkers and graphene-based materials to enhance mechanical properties while maintaining hemocompatibility [11]

Table 1: Advantages and Limitations of pHEMA in Biomedical Applications

| Application | Advantages | Disadvantages | References |

|---|---|---|---|

| Contact Lenses | Inexpensive, biocompatible, abundant copolymer possibilities | Protein deposition issues | [9] |

| Bone Tissue Generation | Biocompatibility, excellent adhesion-promoting to other polymers, elastomeric properties | Non-degradable, requiring cross-linker | [9] |

| Wound Healing | Transparency, biocompatibility | Low exudate absorbability, non-degradable, requiring cross-linker | [9] |

| Cancer Therapy | Stimuli-responsive, inexpensive, easily combined with different polymers and drugs | Non-degradable, requiring cross-linker | [9] |

Evolution of pHEMA-Based Contact Lens Manufacturing

Initial Production Challenges

Wichterle's early attempts at lens manufacturing in 1957 involved producing approximately 100 soft lenses from closed polystyrene molds [7]. However, these initial efforts faced significant technical challenges: material contraction during polymerization caused edges to split and tear during removal from molds [7]. Each imperfect lens required manual finishing with a fingernail file, highlighting the need for a more sophisticated manufacturing approach [7].

The development of centrifugal casting in 1961 represented the critical innovation that enabled viable lens production [8]. This process utilized pHEMA's unique properties under rotational forces, allowing precise lens formation with consistent optical qualities and edge integrity.

Manufacturing Workflow: Historical to Contemporary

The original manufacturing process developed by Wichterle has evolved into sophisticated modern protocols. The following workflow diagrams capture both historical and contemporary approaches to pHEMA hydrogel contact lens production.

Advanced Material Formulations

Contemporary research continues to enhance pHEMA's properties for improved contact lens performance. Recent innovations include:

- Enhanced Mechanical Properties: pHEMA hydrogels fabricated in water/ionic liquid mixtures achieve elongation at break up to 705% and tensile strength up to 173 kPa at swollen equilibrium states while maintaining high transparency [12]

- Antimicrobial Strategies: Incorporation of silver nanoparticles, antibiotics, and antimicrobial agents to protect against microbial keratitis [9]

- Drug-Eluting Systems: Development of pHEMA-based lenses for controlled ocular drug delivery with zero-order release kinetics [10]

Table 2: Quantitative Properties of Advanced pHEMA Hydrogels

| Property | Standard pHEMA | Enhanced pHEMA [12] | Measurement Conditions |

|---|---|---|---|

| Tensile Strength | ~50-100 kPa | Up to 173 kPa | Swollen equilibrium state |

| Elongation at Break | ~200-400% | Up to 705% | Swollen equilibrium state |

| Light Transmittance | >90% | >90% | Visible spectrum |

| Water Content | 38-42% | 38-42% | Equilibrium in saline |

| Oxygen Permeability (Dk) | 8-12 barrers | 8-12 barrers | 35°C |

Experimental Protocols

Protocol 1: Synthesis of pHEMA Hydrogels for Contact Lens Applications

Principle: pHEMA hydrogels are formed through free radical polymerization of HEMA monomer in the presence of a cross-linking agent, creating a three-dimensional network that swells in water [9] [2].

Materials:

- 2-hydroxyethyl methacrylate (HEMA) monomer

- Ethylene glycol dimethacrylate (EGDMA) cross-linker

- Photoinitiator (e.g., Irgacure 2959)

- Deionized water

- Nitrogen gas for degassing

- UV light source (305 nm)

Procedure:

- Solution Preparation: Combine HEMA (11.6 mL) with EGDMA (44 μL) in deionized water (8.6 mL) [10]

- Initiation: Add photoinitiator (100 μL of 0.1 g/mL in DMSO) to the monomer solution [10]

- Degassing: Purge the solution with nitrogen gas for 40 minutes to remove oxygen which inhibits polymerization [10]

- Molding: Transfer 160 μL of solution into a 100-μm-deep cylindrical rubber mold (16 mm diameter) [10]

- Polymerization: Cover with a glass slide and polymerize with 305-nm UV light for 60 minutes in a nitrogen environment [10]

- Hydration: Carefully remove the polymerized hydrogel and hydrate in sterile saline solution for 24 hours

- Characterization: Evaluate physical properties including water content, transparency, and mechanical strength

Technical Notes:

- Monomer to cross-linker ratio significantly affects mechanical properties and swelling behavior [9]

- For enhanced mechanical properties, consider polymerization in water/ionic liquid mixtures (e.g., 1-butyl-3-methylimidazolium chloride) [12]

- Sterilization methods (autoclave, gamma irradiation) may affect hydrogel properties and require validation

Protocol 2: Fabrication of Drug-Eluting pHEMA Contact Lenses

Principle: This protocol describes creating a drug-eluting contact lens using a dual polymer system with a PLGA drug core coated with pHEMA, enabling sustained drug release [10].

Materials:

- PLGA (65% lactic acid, 35% glycolic acid; 118-kDa or 18-kDa molecular mass)

- Therapeutic agent (e.g., ciprofloxacin, fluorescein)

- Ethyl acetate

- HEMA monomer and cross-linker components (as in Protocol 1)

- Teflon casting wells

- Lyophilizer

Procedure: A. Drug-Polymer Film Fabrication:

- Dissolve PLGA in ethyl acetate (15 mL) [10]

- Add drug compound (e.g., 20 mg ciprofloxacin) and mix to form uniform suspension [10]

- Pour suspension into Teflon well and evaporate ethyl acetate overnight in fume hood [10]

- Lyophilize for 48 hours to remove residual solvent [10]

- Punch rings with 14-mm outer diameter and 5-mm central aperture from drug-PLGA film [10]

B. pHEMA Coating:

- Prepare pHEMA solution as described in Protocol 1 [10]

- Polymerize a thin bottom pHEMA layer in mold using UV light [10]

- Manually press drug-PLGA film onto the dried pHEMA gel [10]

- Add additional pHEMA solution to fully encapsulate the drug-polymer film [10]

- Complete polymerization with UV light for 60 minutes [10]

C. Drug Release Characterization:

- Conduct release studies in phosphate-buffered saline at 37°C with continuous shaking [10]

- Sample release medium at predetermined intervals and analyze drug concentration

- Verify antimicrobial efficacy of released compounds using appropriate assays [10]

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents for pHEMA Hydrogel Contact Lens Research

| Reagent/Material | Function | Research Considerations | References |

|---|---|---|---|

| HEMA Monomer | Primary building block for hydrogel formation | Purify to remove inhibitors; toxic in monomer form but safe when polymerized | [9] [10] |

| EGDMA Cross-linker | Creates 3D network structure; controls mesh size | Concentration affects mechanical properties and swelling ratio | [10] |

| Irgacure 2959 | Photoinitiator for UV polymerization | Concentration affects polymerization rate and final properties | [10] |

| PLGA (65:35 LA:GA) | Biodegradable polymer for drug-eluting systems | Molecular weight (18-118 kDa) controls drug release kinetics | [10] |

| Ionic Liquids (BmimCl) | Enhances mechanical properties | Creates denser, more homogeneous microstructure in pHEMA | [12] |

| Hydroxyapatite | Ceramic component for composite hydrogels | Enhances bioactivity for bone tissue applications | [9] |

| Antimicrobial Agents | Prevents microbial colonization | Silver nanoparticles, antibiotics reduce infection risk | [9] |

Contemporary Applications and Future Perspectives

Advanced Contact Lens Technologies

Modern contact lens technology continues to build upon Wichterle's pHEMA foundation with several key advancements:

- Multifocal Designs: Latest innovations include daily disposable multifocal contact lenses incorporating blue light filtration (OptiBlue Light Filter), tear film stabilization (TearStable Technology), and blink-stabilized designs [13]

- Myopia Management: Increasing focus on contact lenses for childhood myopia control, with research supporting their efficacy in slowing myopia progression [14]

- Smart Lens Technologies: Development of electronics-free contact lenses capable of monitoring intraocular pressure in real-world conditions (miLens) [14]

Integration of Artificial Intelligence

The field of contact lens management is increasingly incorporating artificial intelligence to enhance clinical outcomes:

- AI-Driven Diagnostics: Machine learning algorithms analyze ocular images for precise fitting and complication detection [15]

- Predictive Modeling: AI tools anticipate patient needs and potential complications, enabling proactive care [15]

- Digital Patient Management: Hybrid care platforms combine in-person visits with remote monitoring to improve patient adherence and retention [15]

Future Research Directions

The future of pHEMA hydrogels in contact lens applications includes several promising research avenues:

- Enhanced Material Properties: Continued development of pHEMA composites with improved oxygen permeability, mechanical strength, and surface wettability [2] [12]

- Personalized Medicine: Lens customization based on individual ocular parameters and therapeutic needs [15]

- Extended Drug Delivery: Advancement of drug-eluting systems capable of sustained release over weeks to months [10]

- Biointegrated Sensors: Development of diagnostic contact lenses capable of monitoring physiological parameters and disease markers [14]

The legacy of Otto Wichterle's invention continues to drive innovation in ocular biomaterials, with pHEMA remaining a foundational polymer for both current applications and future breakthroughs in contact lens technology. The integration of material science, pharmaceutical technology, and digital health platforms promises to further enhance the functionality and therapeutic potential of pHEMA-based contact lenses in the coming decades.

Quantitative Material Properties of PHEMA Hydrogels

The utility of poly(2-hydroxyethyl methacrylate) (PHEMA) hydrogels in contact lens applications is quantified by a set of critical physical, mechanical, and optical properties. These characteristics, derived from its polymer network structure, directly dictate its performance and comfort as an ophthalmic biomaterial [16].

Table 1: Key Properties of PHEMA Hydrogels for Contact Lens Applications

| Property | Typical Range/Value | Functional Significance in Contact Lenses |

|---|---|---|

| Water Content | 20% to 80% [16] | Enhances oxygen permeability and wearer comfort; mimics the hydrated ocular surface. |

| Tensile Strength | 0.12 - 0.2 MPa [16] | Provides sufficient mechanical integrity to withstand handling and eyelid forces during blinking. |

| Young's Modulus | 0.4 - 1.8 MPa [16] | Imparts softness and flexibility, ensuring comfort on the sensitive corneal tissue. |

| Oxygen Permeability | Correlates with water content [16] | Facilitates corneal oxygenation during wear, which is critical for ocular health. |

| Optical Clarity | High transparency [2] | Ensures unimpaired vision, a fundamental requirement for any optical device. |

Experimental Protocols

Protocol: Synthesis of PHEMA Hydrogels via Bulk Polymerization

This protocol describes the synthesis of PHEMA hydrogels through free radical polymerization, adapted from foundational research on polymerization kinetics [17].

Research Reagent Solutions

- Monomer: 2-hydroxyethyl methacrylate (HEMA). Function: Primary building block of the polymer network. Must be purified by passing through an inhibitor-remover column prior to use [17].

- Crosslinking Agent: Ethylene glycol dimethacrylate (EGDMA) or poly(ethylene glycol) diacrylate (PEGDA). Function: Creates covalent bridges between polymer chains, forming a three-dimensional network that provides mechanical stability and controls swelling [18] [16].

- Initiator: Benzoyl peroxide (BPO) for thermal initiation. Function: Generates free radicals upon heating to initiate the polymerization reaction [17].

- Photoinitiator (Alternative): 1-hydroxycyclohexyl phenyl ketone (HCHPK). Function: Generates free radicals upon exposure to UV light for photopolymerization [18].

Procedure

- Monomer Purification: Pass HEMA monomer through an inhibitor-remover packed column at least twice to remove the hydroquinone monomethyl ether (MEHQ) stabilizer [17].

- Reaction Mixture Preparation: In a glass vial, combine purified HEMA (e.g., 9.5 mL), crosslinking agent (e.g., EGDMA at 0.1-4 mol%), and thermal initiator (e.g., BPO at 0.03 mol/L). Mix thoroughly until a homogeneous solution is obtained [17] [18].

- Degassing (Optional but Recommended): Sparge the mixture with an inert gas (e.g., nitrogen or argon) for 10-15 minutes to remove dissolved oxygen, which can inhibit free radical polymerization.

- Casting and Sealing: Pipette the reaction mixture into an appropriate mold (e.g., a glass mold with a silicone gasket to define thickness). Seal the mold to prevent solvent evaporation and oxygen ingress.

- Polymerization: Place the sealed mold in an oven or thermal chamber. Cure isothermally at a temperature between 52°C and 82°C for a duration sufficient to achieve high conversion (e.g., several hours). The reaction is highly exothermic, particularly during the autoacceleration phase [17].

- Post-Processing: After polymerization, carefully demold the PHEMA hydrogel. Wash the hydrogel extensively in distilled water or an appropriate solvent to remove any unreacted monomers, initiator residues, and sol fraction. Change the washing solution multiple times over 24-48 hours [18].

- Hydration and Storage: Equilibrate the purified hydrogel in a sterile saline solution or buffered solution. Store the hydrated hydrogel in a sealed container at 4°C.

Diagram 1: PHEMA hydrogel synthesis workflow.

Protocol: Characterization of Swelling Behavior and Hydration

Understanding the water uptake capacity and kinetics is essential for predicting hydrogel comfort and oxygen transmissibility [19] [18].

Procedure

- Sample Preparation: Synthesize PHEMA hydrogels as described in Protocol 2.1. Cut into standardized discs (e.g., 10 mm diameter) and dry in a vacuum oven at 50°C until constant weight is achieved (Wd).

- Equilibrium Swelling: Immerse the dried hydrogel discs in a large volume of phosphate-buffered saline (PBS) at a physiological temperature (e.g., 34°C to simulate ocular surface temperature). Allow the hydrogels to swell until equilibrium is reached (typically 24-48 hours).

- Weighing: Remove the hydrogel from the PBS at predetermined time intervals, gently blot with lint-free tissue to remove surface water, and immediately weigh (Ws). Return the hydrogel to the PBS after each measurement until the weight stabilizes.

- Calculation: Calculate the equilibrium water content (EWC) using the formula:

- EWC (%) = [(Ws - Wd) / Ws] × 100

Table 2: Swelling and Mechanical Characterization Methods

| Characterization Method | Measured Parameters | Application in PHEMA Hydrogel Analysis |

|---|---|---|

| Gravimetric Swelling Analysis | Equilibrium Water Content (EWC), Swelling Kinetics | Quantifies hydration capacity and rate, directly related to oxygen permeability and comfort [18]. |

| Rheology | Storage Modulus (G'), Loss Modulus (G''), Mesh Size (ξ) | Determines mechanical stability (G' ~10 kPa suitable for dermal use), viscoelasticity, and network structure which influences drug diffusion [19]. |

| Differential Scanning Calorimetry (DSC) | Polymerization Rate, Conversion, Reaction Enthalpy | Monitors polymerization kinetics, determines degree of monomer conversion, and studies thermal transitions [17]. |

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for PHEMA Hydrogel Research

| Reagent/Chemical | Function in Research | Key Consideration |

|---|---|---|

| 2-Hydroxyethyl Methacrylate (HEMA) | Primary monomer for constructing the hydrogel polymer network. | Requires purification to remove polymerization inhibitors (e.g., MEHQ) before use for reproducible kinetics [17]. |

| Poly(Ethylene Glycol) Diacrylate (PEGDA) | A biocompatible crosslinker that defines the network's mesh size and mechanical properties. | The molecular weight and concentration allow tuning of hydrogel stiffness and permeability [18]. |

| Benzoyl Peroxide (BPO) | Thermal free-radical initiator for polymerization. | Must be purified via recrystallization for consistent initiation rates and reaction kinetics [17]. |

| 1-Hydroxycyclohexyl Phenyl Ketone | UV-photoinitiator for light-induced polymerization, enabling spatial control. | Enables rapid curing and fabrication of complex geometries at room temperature [18]. |

| Ethylene Glycol Dimethacrylate (EGDMA) | A common crosslinking agent used to control the hydrogel's swelling and mechanical strength. | The concentration significantly affects the final water content and modulus of the lens material [16]. |

Diagram 2: From reagents to functional lens properties.

Poly(2-hydroxyethyl methacrylate), or PHEMA, is a foundational synthetic hydrogel in contact lens research, prized for its biocompatibility, soft consistency, and high water content [20] [17] [21]. However, its application is constrained by two intrinsic limitations: insufficient oxygen permeability for extended wear and a limited, often uncontrolled, drug loading capacity. This application note details these material limitations and provides validated experimental protocols for their quantification, providing researchers with the methodologies needed to advance the design of next-generation ophthalmic materials.

Oxygen Permeability Barriers in PHEMA Hydrogels

The Fundamental Limitation

In conventional hydrogels like PHEMA, oxygen is primarily transported through the aqueous phase of the material [22]. This mechanism imposes a fundamental upper limit on oxygen permeability (Dk), as the Dk value of pure water is approximately 80 Barrer [23]. PHEMA-based contact lenses typically contain up to only 38% water by mass, which further restricts their oxygen transmissibility [20]. This low permeability can cause the lens to act as a barrier, potentially leading to corneal hypoxia, a condition associated with corneal swelling, red eyes, and other pathological changes [23] [22] [21].

Table 1: Oxygen Permeability and Water Content of Hydrogel Materials

| Material Type | Typical Water Content (%) | Oxygen Permeability (Dk, Barrer or Fatt units) | Primary Oxygen Transport Pathway |

|---|---|---|---|

| PHEMA Homopolymer | ~38% [20] | Below 60 [22] | Water phase [22] |

| Non-Silicone Hydrogel (DMAA-based) | 75-81% [22] | Up to 73.9 [22] | Water phase [22] |

| Silicone Hydrogel (SiHy) | Varies | >100 (can exceed 140) [23] [22] | Hydrophobic silicone phase [23] [22] |

| Pure Water | 100% | ~80 [23] | N/A |

Experimental Protocol: Coulometric Measurement of Oxygen Permeability

Principle: The coulometric method determines oxygen permeability and diffusivity by measuring the flux of oxygen through a hydrogel membrane under a controlled pressure gradient [23].

Materials & Reagents:

- Test Hydrogel Samples: PHEMA sheets or lenses of uniform thickness.

- Coulometric Permeability Cell: Consisting of two chambers separated by the test sample.

- Gas Flow System: For delivering humidified nitrogen (carrier gas) and oxygen (test gas).

- Oxygen Sensor: A coulometric sensor to detect the oxygen flux.

- Data Acquisition System: To record the transient flux response.

Procedure:

- Sample Preparation: Hydrate the PHEMA hydrogel samples in a saline solution until equilibrium swelling is achieved. Precisely measure and record the sample thickness.

- Cell Assembly: Mount the hydrated sample securely in the permeability cell, ensuring no edge leaks.

- Gas Humidification: Bubble both the carrier (N₂) and test (O₂) gases through a water bath to humidify them, preventing sample dehydration during testing.

- Flux Measurement: Expose one side of the sample to humidified O₂ while the other side is purged with humidified N₂, which carries any permeating oxygen to the sensor.

- Data Recording: Record the oxygen flux as a function of time until a steady state is reached.

- Data Analysis: Fit the transient flux data to a mathematical model (e.g., a solution to Fick's law) to calculate the oxygen diffusivity (D) and solubility (k). The oxygen permeability (P) is then calculated as the product: ( P = D \times k ) [23].

Drug Loading Capacity and Release Control

The Challenge of Uncontrolled Release

While PHEMA hydrogels can absorb aqueous drug solutions, a significant limitation is the rapid, uncontrolled release of the loaded therapeutic agent [24]. Simple impregnation methods often lead to a burst release, where a large portion of the drug is released within a short period. This fails to sustain therapeutic concentrations over a clinically useful duration, such as a full day of wear [24]. The primary mechanism for drug transport is diffusion through the water-filled pores of the hydrogel, which, without strategic modification, offers little resistance to rapid drug elution.

Table 2: Key Properties of PHEMA Affecting Drug Loading and Release

| Property | Impact on Drug Delivery | Typical Value / Characteristic for PHEMA |

|---|---|---|

| Water Content | Determines loading capacity for hydrophilic drugs; higher content can weaken polymer network [24]. | ~38% by mass [20]. |

| Polymer Network Mesh Size | Controls diffusion rate of drugs; determined by crosslink density [24]. | Adjustable via crosslinker concentration [17] [25]. |

| Glass Transition Temperature (Tg) | Reflects polymer chain mobility; a stable Tg indicates drug loading does not compromise matrix integrity [24]. | ~425 K (simulated) [20]; remains stable with drug impregnation [24]. |

| Transparency | Essential for functionality; must not be impaired by drug or loading method [24]. | High transparency (up to 99.91% transmittance in similar hydrogels) [22]. |

Experimental Protocol: In-Situ Polymerization for Drug-Loaded PHEMA

Principle: This protocol involves polymerizing HEMA in the presence of a drug and a crosslinker to create a hydrogel matrix where the drug is entrapped within the polymer network, offering more controlled release than post-polymerization soaking.

Materials & Reagents:

- Monomer: 2-hydroxyethyl methacrylate (HEMA).

- Crosslinker: Ethylene glycol dimethacrylate (EGDMA).

- Initiator: UV initiator (e.g., Irgacure 1173) or thermal initiator (e.g., Benzoyl Peroxide, BPO).

- Solvent/Diluent: Deionized water.

- Therapeutic Agent: Drug of choice (e.g., Timolol maleate for glaucoma).

- Molds: Customized lenses or slab molds.

- UV Chamber: For photopolymerization (if using a UV initiator).

Procedure:

- Inhibitor Removal: Pass HEMA monomer through an inhibitor-remover column to ensure efficient polymerization [25].

- Reaction Mixture Preparation: Combine the purified HEMA, deionized water, EGDMA crosslinker, initiator, and the target drug. A typical formulation by weight is 63% HEMA, 35% water, 1% EGDMA, and 1% initiator [25]. Stir the mixture until clear.

- Molding and Polymerization: Pour the solution into pre-designed molds. For UV polymerization, expose the molds to UV light (e.g., 365 nm, 100 W) for 10 minutes [25]. For thermal polymerization, place the molds in an oven at a temperature suitable for the initiator (e.g., 52-82°C for BPO) [17].

- Post-Processing and Hydration: Carefully demold the polymerized drug-loaded hydrogel. Hydrate the lenses in a buffered saline solution to remove any unreacted monomers and to achieve equilibrium swelling before release testing.

- Drug Release Kinetics: Immerse the hydrated drug-loaded lens in a known volume of release medium (e.g., phosphate-buffered saline) under constant agitation. Periodically withdraw samples from the medium and analyze the drug concentration using a validated method (e.g., HPLC or UV-Vis spectroscopy) to construct a release profile over time.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for PHEMA Hydrogel Research

| Reagent/Material | Function in Research | Example & Notes |

|---|---|---|

| HEMA Monomer | Primary building block of the hydrogel polymer network. | Requires removal of inhibitor (e.g., monomethyl ether hydroquinone) prior to polymerization [25]. |

| Crosslinker (e.g., EGDMA) | Creates covalent bridges between polymer chains, controlling mesh size and mechanical strength. | Concentration and chain length (e.g., 1-EGDMA, 23-EGDMA) significantly impact oxygen permeability and water content [22] [25]. |

| Polymerization Initiator | Generates free radicals to initiate the chain-growth polymerization reaction. | UV Initiator (Irgacure 1173): For photopolymerization [25]. Thermal Initiator (BPO): For thermal polymerization [17]. |

| Hydrophilic Comonomer (e.g., NVP) | Increases the water content of the PHEMA matrix. | N-Vinylpyrrolidone (NVP) is common; forms P(VP-co-HEMA) copolymers with water content up to 60% [20]. |

| Silicone Monomer (e.g., TRIS, mPDMS) | Enhances oxygen permeability by creating a separate oxygen-transport phase. | Used in silicone hydrogels; inherently hydrophobic and can phase-separate [23]. |

| Model Drug Compounds | For testing drug loading and release profiles. | Timolol maleate (glaucoma) and acetazolamide are used in impregnation studies [24]. |

Advanced Fabrication and Functionalization of PHEMA for Therapeutic Applications

Synthesis and Manufacturing Techniques for PHEMA Hydrogel Lenses

Poly(2-hydroxyethyl methacrylate) (pHEMA) hydrogels have been a cornerstone of contact lens technology since their initial development by Wichterle and Lim in the 1960s [1]. These cross-linked, three-dimensional polymeric networks revolutionized vision correction by offering a biocompatible, oxygen-permeable, and transparent material that could be comfortably worn on the eye [21]. Despite their long-standing use, traditional pHEMA hydrogels face significant limitations including relatively low oxygen permeability, susceptibility to tear protein deposition, and limited functionality for therapeutic applications [1] [26].

Recent research has focused on developing advanced copolymerization strategies and surface modification techniques to address these challenges while maintaining the favorable biocompatibility of pHEMA [27]. This Application Note details contemporary synthesis methodologies and manufacturing protocols for fabricating both conventional and next-generation pHEMA-based hydrogel contact lenses, with particular emphasis on functionalized materials offering improved hydrophilicity, mechanical properties, and sustained drug delivery capabilities for ophthalmic applications.

Fundamental Synthesis Protocols

Conventional pHEMA Hydrogel Synthesis

The synthesis of standard pHEMA hydrogels follows a well-established protocol of free radical polymerization using 2-hydroxyethyl methacrylate (HEMA) monomer with a small molecular crosslinker [1].

Protocol: Basic pHEMA Hydrogel Formation

Reagents Required:

- 2-hydroxyethyl methacrylate (HEMA) monomer

- Crosslinking agent: ethylene glycol dimethacrylate (EGDMA)

- Photoinitiator: 2,2-dimethoxy-2-phenylacetophenone (DMPA) or thermal initiator

- Solvent: Deionized water

- Inhibitor remover beads (if HEMA contains inhibitor)

Procedure:

- Inhibitor Removal: If the HEMA monomer contains monomethyl ether hydroquinone as an inhibitor, pass 30 mL of HEMA through 10 mg of inhibitor remover beads with stirring for approximately 3 minutes. Filter the solution to remove the beads [25].

- Solution Preparation: Combine the purified HEMA (63% w/w) with deionized water (35% w/w), EGDMA crosslinker (1% w/w), and the photoinitiator DMPA (1% w/w). Stir the mixture until it becomes clear and homogeneous [25].

- Molding: Pour the solution into appropriate molds designed for the desired contact lens geometry. For laboratory-scale prototyping, this can involve sandwiching between glass slides with controlled spacers or using custom-fabricated concave molds.

- Polymerization: Expose the molded solution to ultraviolet radiation (365 nm center wavelength, 100 W) for 10 minutes to initiate photopolymerization. Thermal initiation using ammonium persulfate (APS) is a common alternative [1] [25].

- Post-Processing: Carefully demold the polymerized hydrogel. The resulting lens must be hydrated in a saline solution and subjected to rigorous extraction and washing processes to remove any unreacted monomers, initiators, or solvent residues, which is critical for ensuring biocompatibility [28].

Synthesis of Functionalized p(HEMA-co-mHA-β-CD) Hydrogel

To overcome the limitations of conventional pHEMA, a functional copolymer incorporating methacrylated hyaluronan-β-cyclodextrin (mHA-β-CD) has been developed [1].

Protocol: Synthesis of mHA-β-CD Comonomer and Copolymerization

Reagents Required:

- Sodium hyaluronan (HA)

- β-cyclodextrin (β-CD)

- Methacrylic anhydride (MA)

- 1,6-hexanediamine (HDA)

- p-toluenesulfonyl chloride (p-TsCl)

- Coupling agents: 1-(3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC•HCl) and N-hydroxysuccinimide (NHS)

Procedure:

- Synthesis of mHA-β-CD Derivative:

- Activation of β-CD: React β-CD with p-TsCl to form mono-tosyl-β-CD (M-6-O-Ts-β-CD).

- Amination: Substitute the tosyl group with 1,6-hexanediamine (HDA) to create β-CD-HDA.

- Methacrylation of HA: React HA with methacrylic anhydride to form methacrylated hyaluronic acid (mHA).

- Conjugation: Covalently link the amine groups of β-CD-HDA to the carboxyl groups of mHA using EDC•HCl and NHS as coupling agents, resulting in the mHA-β-CD macromer [1].

- Copolymerization:

- Combine the synthesized mHA-β-CD macromer with HEMA monomer in aqueous solution.

- Use ammonium persulfate (APS) as an initiator for the free radical copolymerization.

- The mHA-β-CD acts as a multifunctional hydrophilic comonomer and macromolecular crosslinker, forming a robust p(HEMA-co-mHA-β-CD) hydrogel network without the need for additional small-molecule crosslinkers like EGDMA [1].

- Synthesis of mHA-β-CD Derivative:

Diagram 1: Experimental workflow for the synthesis of pHEMA-based hydrogels, highlighting key stages from monomer preparation to final characterization.

Material Characterization and Performance Data

The evaluation of synthesized hydrogel lenses involves a comprehensive analysis of their physical, optical, and biological properties to ensure they meet the stringent requirements for ophthalmic use.

Table 1: Comparative Properties of Conventional and Advanced pHEMA-based Hydrogels

| Property | Conventional pHEMA | p(HEMA-co-mHA-β-CD) [1] | pHEMA/β-CD-crHA [26] | Test Method/Aonditions |

|---|---|---|---|---|

| Water Contact Angle (°) | ~80 [1] | 53.8 - 64.5 | ~60 | Static water contact angle measurement |

| Equilibrium Water Content (%) | ~30 [1] | 44.5 - 52.9 | ~55 | Gravimetric analysis after hydration |

| Tensile Strength (MPa) | Baseline | 0.18 - 0.39 | - | Universal testing machine |

| Elongation at Break (%) | Baseline | 112.3 - 185.8 | - | Universal testing machine |

| Light Transmittance (%) | >90 (at 550 nm) [27] | >90 (at 550 nm) | >90 | UV-Vis spectrophotometer |

| Lysozyme Deposition (μg/lens) | High | Significantly Reduced | Significantly Reduced | SDS-PAGE or direct quantification |

| Oxygen Permeability (Dk) | Low | Improved | Improved | Polarographic method |

Table 2: Formulation and Function of Key Research Reagent Solutions

| Reagent | Function/Role in Synthesis | Typical Concentration | Critical Notes |

|---|---|---|---|

| 2-Hydroxyethyl methacrylate (HEMA) | Primary monomer; forms hydrogel backbone | 63% (w/w) in standard recipe [25] | Requires inhibitor removal prior to polymerization |

| Ethylene glycol dimethacrylate (EGDMA) | Small molecular crosslinker; controls network density | 1% (w/w) [25] | Concentration inversely related to equilibrium water content |

| Ammonium Persulfate (APS) | Thermal initiator for free radical polymerization | Varies | Common for bulk polymerization; requires purification post-synthesis |

| 2,2-dimethoxy-2-phenylacetophenone (DMPA) | Photoinitiator for UV-induced polymerization | 1% (w/w) [25] | Enables rapid curing at room temperature |

| Methacrylated Hyaluronan (mHA) | Rigid, hydrophilic comonomer; improves mechanics & wettability | Varies by desired property | Provides active carboxyl and hydroxyl groups for further modification |

| β-Cyclodextrin (β-CD) | Functional additive; enables sustained drug delivery via host-guest complexes | Varies by desired property | Hydrophobic cavity encapsulates drugs; must be covalently bonded to prevent leaching |

Advanced Manufacturing and Surface Engineering

Surface Patterning via Replica Molding

Nanostructuring the lens surface can significantly influence its interaction with ocular tissues and proteins.

Protocol: Replica Mold Nanopatterning of pHEMA Surfaces [27]

Reagents/Materials:

- Silicon wafer with native oxide layer

- pHEMA hydrogel precursor solution

- Focused Ion Beam (FIB) system

Procedure:

- Fabrication of Master Mold: Use a Focused Ion Beam (FIB) to mill an array of nanoscale holes (e.g., tens of nanometers deep) into a silicon wafer, creating a negative pattern of the desired surface features.

- Replica Molding: Pour the standard pHEMA precursor solution onto the fabricated silicon stamp mold.

- Polymerization: Carry out photopolymerization under UV light to cure the hydrogel, thereby transferring the nanopattern from the mold to the hydrogel surface.

- Demolding: Carefully peel the fully polymerized and patterned hydrogel from the mold. The resulting hydrogel surface features randomly distributed nanopillars, which have been shown to potentially suppress the upregulation of cytoskeleton proteins in cells, offering a strategy to prevent conditions like secondary cataracts in intraocular lenses [27].

Interpenetrating Networks and Combination with Silicone

For applications requiring very high oxygen permeability, pHEMA can be combined with silicone-based polymers to form interpenetrating networks (IPNs) or copolymer systems [29].

Table 3: Properties of a Silicone-Hydrogel Combining PDMS and pHEMA-based Polymers [29]

| Property | Trend with Increasing Silicone Content | Impact on Lens Performance |

|---|---|---|

| Oxygen Permeability (Dk) | Increases | Reduces risk of corneal hypoxia, supports extended wear |

| Equilibrium Water Content | Decreases | Can affect comfort and hydration; requires balance |

| Water Contact Angle | Increases (more hydrophobic) | May reduce wettability; necessitates surface treatments |

| Young's Modulus | Decreases | Softer lens, potentially improving comfort |

| Protein Deposition | Varies with hydrophilicity | Lysozyme deposition increases with hydrophilicity of the final formulation |

Diagram 2: Logical relationship between inherent limitations of conventional pHEMA and the advanced material strategies developed to address them, leading to improved functional outcomes.

The synthesis and manufacturing of pHEMA hydrogel lenses have evolved significantly from the basic cross-linked networks first introduced decades ago. The protocols detailed herein—ranging from conventional polymerization to advanced functionalization with mHA-β-CD, and from surface nanopatterning to the formation of silicone IPNs—provide a robust toolkit for researchers and material scientists. These strategies directly address the historical limitations of pHEMA, enabling the creation of next-generation contact lenses with superior comfort, enhanced resistance to protein deposition, and advanced capabilities such as sustained drug delivery. The quantitative data presented confirms that these advanced materials meet the critical optical, mechanical, and biological requirements for successful ophthalmic application, paving the way for their use in both corrective and therapeutic vision care.

The efficacy of conventional ophthalmic treatments, such as eye drops, is significantly limited by physiological barriers and rapid clearance mechanisms, resulting in less than 5% drug bioavailability [30]. Poly(2-hydroxyethyl methacrylate) (PHEMA) hydrogels, a cornerstone material in contact lens fabrication, provide an ideal platform for innovative ocular drug delivery systems. This application note details three primary drug loading methodologies—soaking, molecular imprinting, and physical encapsulation—framed within ongoing thesis research on enhancing PHEMA hydrogel functionality. These methods are engineered to overcome bioavailability challenges by enabling sustained, controlled release of therapeutics directly to the ocular surface, thereby improving treatment outcomes for conditions like glaucoma, dry eye syndrome, and post-surgical inflammation [31] [30] [32].

Performance Comparison of Drug Loading Techniques

The table below summarizes the key characteristics, advantages, and limitations of the three primary drug loading methods as applied to PHEMA-based hydrogels.

Table 1: Comparative Analysis of Drug Loading Techniques for PHEMA Hydrogels

| Loading Method | Mechanism of Action | Sustained Release Duration | Key Advantages | Inherent Limitations |

|---|---|---|---|---|

| Soaking | Passive diffusion of drug molecules from a solution into the hydrogel matrix [33]. | Hours to a few days [34]. | Simple, cost-effective, compatible with commercial lenses [34]. | Limited control, typically exhibits high initial burst release, lower loading capacity [35] [32]. |

| Molecular Imprinting | Creation of specific molecular cavities within the polymer network that exhibit high affinity for a target drug molecule [35] [36]. | Several days to weeks [37]. | High loading capacity, programmable and sustained release, reduces initial burst effect [35] [36]. | Complex fabrication, requires optimization of functional monomer and cross-linker ratios [35] [36]. |

| Physical Encapsulation | Entrapment of drug within a polymeric barrier or nanoparticle dispersed in the hydrogel [31] [30]. | Days to weeks [31] [34]. | Excellent sustained release, protects drug stability, can be combined with other methods [31] [30]. | Potential impact on lens transparency and mechanical properties, complex manufacturing [31] [30]. |

Experimental Protocols

Protocol 1: Drug Loading via the Soaking Method

The soaking method is a straightforward approach to passively load drugs into pre-formed PHEMA contact lenses.

Table 2: Key Reagents for Soaking and Molecular Imprinting

| Reagent Name | Function/Application |

|---|---|

| Senofilcon A or Hilafilcon B Lenses | Pre-formed commercial hydrogel lenses used as substrates for drug loading [33]. |

| Vitamin C (Ascorbic Acid) | A model hydrophilic drug compound for studying loading and release kinetics [33]. |

| Simulated Lacrimal Fluid (SLF) | A pH 7.5 solution mimicking the ionic composition of tears, used for in vitro release studies [36]. |

| N-Vinyl Pyrrolidone (NVP) | A functional monomer used in molecular imprinting to create hydrogen bonds with target drug molecules [35]. |

| Ethylene Glycol Dimethacrylate (EGDMA) | A cross-linking agent that creates a stable three-dimensional network in imprinted hydrogels [35] [36]. |

| Methacrylic Acid (MAA) | A functional monomer that provides ionic interaction sites for drugs containing amino groups [36]. |

Procedure:

- Preparation of Drug Solution: Dissolve the target drug (e.g., Vitamin C, timolol) in a suitable solvent, typically deionized water or a buffer, to a known concentration (e.g., 5 mg/mL for moxifloxacin) [31] [33].

- Lens Immersion: Fully immerse the pre-hydrated or dry PHEMA-based hydrogel lenses in the drug solution. Ensure the lenses are completely submerged and free of air bubbles.

- Loading Incubation: Allow the lenses to soak for a predetermined period (e.g., 24-72 hours) at a controlled temperature (e.g., 25°C or 37°C) with gentle agitation to reach equilibrium saturation [33] [34].

- Post-Loading Rinse: After incubation, remove the lenses from the solution and gently rinse them with a small volume of DI water to remove surface-adhered drug crystals.

- Storage: The drug-loaded lenses can be stored in a sealed vial with a small amount of saline or buffer to maintain hydration before use or release testing [33].

Protocol 2: Drug Loading via Molecular Imprinting

Molecular imprinting creates a macromolecular "memory" within the PHEMA matrix for sustained and targeted release. The following workflow details the fabrication process.

Procedure:

- Computational Screening (Optional but Recommended): Use computational modeling (e.g., molecular dynamics) to screen functional monomers (e.g., NVP, MAA) for their binding affinity with the template drug molecule (e.g., naringenin, valacyclovir) [35] [36].

- Polymerization Mixture Preparation: Prepare a mixture containing:

- Polymerization: Cast the mixture into contact lens molds and initiate free radical polymerization under controlled temperature or UV irradiation [35].

- Template Extraction: After polymerization, immerse the formed hydrogels in a suitable solvent (e.g., ethanol:water mixture) to leach out the template drug molecules. This process leaves behind specific molecular cavities complementary in size, shape, and functional groups to the drug [35] [36].

- Validation: The success of imprinting is validated by comparing the drug loading and sustained release profiles of imprinted lenses against non-imprinted control lenses.

Protocol 3: Drug Loading via Physical Encapsulation

Physical encapsulation relies on creating diffusion barriers within the hydrogel to control drug release.

Table 3: Key Reagents for Physical Encapsulation

| Reagent Name | Function/Application |

|---|---|

| Poly(lactic-co-glycolic) acid (PLGA) | A biodegradable polymer used to form a drug-loaded film that acts as a sustained-release barrier [31]. |

| Vitamin E (Tocopherol) | A hydrophobic additive that creates nanoscale barriers within the hydrogel to slow drug diffusion [31] [34]. |

| Ethylcellulose | A polymer used to form drug-loaded nanoparticles that are subsequently incorporated into the hydrogel matrix [34]. |

| Gold Nanoparticles (GNPs) | Nanocarriers that can be loaded with drugs (e.g., timolol) to enhance accumulation in target tissues [34]. |

| Dexamethasone | A corticosteroid drug model used in encapsulation studies for sustained anti-inflammatory delivery [31]. |

Procedure:

- Barrier Creation: This can be achieved through several strategies:

- Vitamin E Aggregation: Soak pre-formed lenses in a vitamin E-ethanol solution, allowing vitamin E aggregates to form within the polymer matrix and create a hydrophobic diffusion barrier [34].

- Drug-Polymer Film Encapsulation: Mix the drug (e.g., dexamethasone) with a barrier polymer like PLGA. This mixture is then encapsulated as a discrete film within the peripheral region of a methafilcon hydrogel lens during manufacturing, leaving the optical zone clear [31].

- Nanoparticle Incorporation: Pre-load the drug into nanoparticles (e.g., gold nanoparticles, ethylcellulose nanoparticles). These nanoparticles are then dispersed within the HEMA monomer mixture before polymerization [34].

- Lens Fabrication: If the encapsulation occurs during manufacturing (as with film or nanoparticle methods), proceed with standard lens polymerization and curing processes.

- Release Testing: The sustained release capability is evaluated by monitoring drug elution into a medium like SLF over days or weeks, demonstrating significantly extended duration compared to unencapsulated systems [31] [34].

The Scientist's Toolkit

Table 4: Essential Research Reagent Solutions for PHEMA Hydrogel Drug Delivery

| Reagent Solution | Function in Research |

|---|---|

| Simulated Lacrimal Fluid (SLF) | Serves as a physiologically relevant medium for conducting in vitro drug release studies to predict in vivo performance [36]. |

| Methacrylic Acid (MAA) Monomer | An ionic functional monomer used in molecular imprinting to create electrostatic interactions with basic drug molecules (e.g., valacyclovir) [36]. |

| N-Vinyl Pyrrolidone (NVP) Monomer | A non-ionic functional monomer used in molecular imprinting to form hydrogen bonds with drug molecules, enhancing loading and sustaining release [35]. |

| Ethylene Glycol Dimethacrylate (EGDMA) | A cross-linking agent crucial for imparting mechanical stability to the hydrogel and fixing the molecularly imprinted cavities within the polymer network [35] [36]. |

| Vitamin E (α-Tocopherol) Ethanol Solution | Used to create a hydrophobic diffusion barrier within the hydrogel, dramatically extending the release duration of both hydrophilic and hydrophobic drugs [34]. |

Poly(2-hydroxyethyl methacrylate), or pHEMA, is a cornerstone synthetic polymer in the development of biomedical hydrogels, most notably in commercial soft contact lenses, owing to its excellent biocompatibility, optical transparency, and high water absorption capacity [9]. However, for advanced applications such as ocular drug delivery, its inherent limitations—including low drug loading capacity, uncontrolled release profiles, and non-degradability—pose significant challenges [38] [9]. The integration of natural biomaterials presents a powerful strategy to overcome these constraints and enhance the functionality of pHEMA-based systems.

Natural biopolymers such as chitosan, gelatin, and hyaluronic acid offer distinct advantages, including inherent biodegradability, high biocompatibility, and the presence of functional groups that facilitate chemical modification and controlled drug release [38] [39]. Integrating these biopolymers with pHEMA creates composite hydrogels that synergize the robust mechanical properties of the synthetic polymer with the enhanced biofunctionality of natural materials [38] [30]. This document provides detailed application notes and experimental protocols for the development and characterization of these advanced composite materials, framed within the context of ophthalmic drug delivery systems.

Natural Biomaterials for pHEMA Enhancement: Properties and Rationale

The selection of an appropriate natural biomaterial is critical for tailoring the properties of the final pHEMA composite. Below is a summary of the key natural polymers used for enhancing pHEMA.

Table 1: Key Characteristics of Natural Biomaterials for pHEMA Composites

| Natural Biomaterial | Source | Key Functional Groups | Primary Role in pHEMA Composite | Key Advantages |

|---|---|---|---|---|

| Chitosan [38] [39] | Chitin (shellfish) | Amino (-NH₂), Hydroxyl (-OH) | Drug release modulation, Antimicrobial activity | Mucoadhesiveness, biodegradability, intrinsic antibacterial properties. |

| Gelatin [38] [39] | Collagen (animal) | Amino (-NH₂), Carboxyl (-COOH) | Cell adhesion, Mechanical reinforcement | Excellent cell adhesion properties (RGD sequences), thermoresponsive gelation. |

| Hyaluronic Acid (HA) [38] [40] | Bacterial fermentation / Animal tissues | Carboxyl (-COOH), Hydroxyl (-OH) | Hydration, Bioactivity, Drug delivery | High water retention, CD44 receptor targeting, ECM mimicry, biodegradability. |

Synthesis and Fabrication Protocols

Composite hydrogels can be fabricated through several methods, with the choice of method significantly impacting the final material's architecture and properties. The following workflows and protocols outline common approaches.

Composite Fabrication Workflows

Detailed Experimental Protocols

Protocol 1: Synthesis of pHEMA-Gelatin Methacrylate (GelMA) Interpenetrating Network (IPN)

This protocol is adapted from a study fabricating a pHEMA conduit containing a GelMA-HA IPN for nerve regeneration, demonstrating its applicability for creating complex composite structures [41].

- Objective: To create a robust, degradable IPN hydrogel combining pHEMA's mechanical strength with GelMA's bioactivity.

Materials:

- Monomers: 2-hydroxyethyl methacrylate (HEMA)

- Cross-linkers: Ethylene glycol dimethacrylate (EGDMA) for pHEMA; Methacrylic anhydride for GelMA modification

- Initiator: Irgacure 2959 (for UV initiation) or Ammonium persulfate (APS) / Tetramethylethylenediamine (TEMED) (for thermal initiation)

- Natural Polymer: Gelatin (Type A from porcine skin)

- Solvent: Phosphate Buffered Saline (PBS) or deionized water

Procedure:

- Synthesis of GelMA:

- Dissolve gelatin (10% w/v) in PBS at 50°C under constant stirring.

- Slowly add methacrylic anhydride (0.1-0.2 mL per gram of gelatin) to the solution and react for 2-3 hours at 50°C.

- Terminate the reaction by diluting with warm PBS and dialyze against distilled water for 5-7 days to remove impurities and unreacted reagents.

- Lyophilize the purified product to obtain porous GelMA foam. Confirm the degree of methacrylation (can be >90% [41]) via ¹H-NMR.

- Preparation of Pre-polymer Solution:

- Prepare the pHEMA pre-polymer solution by mixing HEMA monomer (56% v/v final concentration [41]), EGDMA cross-linker (0.1-1% v/v), and photo-initiator Irgacure 2959 (0.5% w/v) in a solvent.

- Separately, dissolve the synthesized GelMA (e.g., 5-10% w/v) in PBS containing a photo-initiator at 40°C.

- Fabrication of IPN:

- Mix the pHEMA and GelMA pre-polymer solutions thoroughly.

- Pour the mixture into a polydimethylsiloxane (PDMS) mold designed with the desired contact lens geometry.

- Expose the mold to UV light (e.g., 365 nm, 5-10 mW/cm²) for 30-60 minutes to concurrently polymerize both networks, forming the IPN.

- Post-processing:

- Carefully demold the hydrogel and wash extensively in distilled water or ethanol to remove any unreacted monomers.

- Store the final pHEMA-GelMA IPN in sterile PBS until further use.

- Synthesis of GelMA:

Protocol 2: Coating pHEMA Lenses with Chitosan

This method offers a simpler approach to functionalizing pre-formed pHEMA lenses, significantly altering surface properties without modifying the bulk [38].

- Objective: To impart mucoadhesive and antimicrobial properties to a commercial pHEMA contact lens via a chitosan coating.

Materials:

- Pre-polymerized pHEMA lenses (commercial or lab-made)

- Chitosan (medium molecular weight, >75% deacetylated)

- Acetic acid solution (1% v/v)

- NaOH solution (0.1 M)

- Orbital shaker

Procedure:

- Chitosan Solution Preparation: Dissolve chitosan (1-2% w/v) in an aqueous acetic acid solution (1% v/v). Stir overnight until a clear, homogeneous solution is obtained.

- Lens Pre-treatment: Equilibrate clean pHEMA lenses in distilled water or a mild buffer to hydrate them fully.

- Coating Process: Immerse the hydrated pHEMA lenses in the chitosan solution. Place the container on an orbital shaker set to a low speed (e.g., 50 rpm) for a predetermined time (e.g., 24 hours) to allow for polymer adsorption.

- Cross-linking and Washing: After coating, rinse the lenses gently with distilled water to remove loosely adsorbed chitosan. To stabilize the coating, immerse the lenses in a 0.1 M NaOH solution for 30 minutes to induce physical cross-linking.

- Final Rinsing and Storage: Rinse the coated lenses thoroughly with distilled water until the eluent reaches a neutral pH. Store the lenses in sterile saline solution.

Characterization and Performance Data

Rigorous characterization is essential to validate the success of composite fabrication and assess performance for drug delivery applications.

Material Characterization Workflow

Quantitative Characterization Data

The integration of natural polymers measurably alters the physicochemical properties of pHEMA, as summarized below.

Table 2: Performance Characteristics of pHEMA-Natural Biomaterial Composites

| Composite Type | Drug Loading Method / Agent | Key Findings | Reference |

|---|---|---|---|

| pHEMA-Chitosan Coating | Soaking / Various ophthalmic drugs | Extended drug release duration; Significant increase in bioavailability from ~5% (eye drops) to ~50%. | [38] |

| pHEMA-GelMA-HA IPN | N/A (Structural study) | Tunable degradation profile: Pure HA degraded in ~3 weeks, pure GelMA in >5 weeks. IPN properties can be adjusted by component ratios. | [41] |

| General Natural Polymer-based Lenses | Molecular Imprinting, Soaking, Vitamin E nano-barriers | Achieved sustained drug release over days to weeks, overcoming the initial burst release of pure pHEMA. | [38] [30] |

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Developing pHEMA-Natural Biomaterial Composites

| Reagent / Material | Function | Example & Notes |

|---|---|---|

| HEMA Monomer | Primary building block for the synthetic hydrogel network. | 2-Hydroxyethyl methacrylate. Purify to remove inhibitors before polymerization. |

| Methacrylic Anhydride | Introduces polymerizable methacrylate groups onto natural polymers (e.g., for GelMA, HA-MA). | Enables covalent cross-linking of natural polymers within the pHEMA network. |

| EDC (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide) | Carbodiimide cross-linker for forming amide bonds between carboxyl and amine groups. | Commonly used for conjugating HA (COOH) to chitosan (NH₂) or for grafting. [40] |

| Irgacure 2959 | UV photo-initiator for free radical polymerization. | Ideal for biocompatible applications; requires UV light at ~365 nm for activation. |

| APS/TEMED | Thermal redox initiator system for free radical polymerization. | Ammonium Persulfate (APS) and Tetramethylethylenediamine (TEMED); used for polymerization at room or physiological temperature. |

| Ethylene Glycol Dimethacrylate (EGDMA) | Cross-linking agent for pHEMA, controls mesh size and mechanical strength. | Use at low concentrations (typically 0.1-1% v/v relative to monomer). |

Application Notes for Ophthalmic Drug Delivery

The primary application driving the development of these advanced composites is their use as drug-eluting contact lenses.

Controlled Release Mechanisms: The release kinetics from these composites can be engineered through several mechanisms:

- Diffusion Control: Governed by the mesh size of the hydrogel network, which is tuned by cross-linking density and the presence of the natural polymer.

- Degradation-Mediated Release: For composites containing degradable polymers like GelMA or HA, drug release is coupled to the hydrolysis or enzymatic degradation of the polymer chains, enabling programmable, long-term release [30] [41].

- Ionic/Specific Interactions: Charged drugs can interact ionically with chitosan (cationic) or hyaluronic acid (anionic), providing an additional mechanism to sustain release [38].

Overcoming Commercial Limitations: These composites directly address the critical limitations of commercial contact lenses for drug delivery, which include low drug loading capacity and uncontrolled release kinetics (typically a large initial burst followed by rapid depletion) [38]. The natural biomaterials significantly enhance loading capacity and provide sustained, controlled release, improving therapeutic efficacy and patient compliance.

Future Perspectives and Challenges: While research is promising, the translation of these composite lenses to commercial products faces challenges. These include scaling up manufacturing with high reproducibility, ensuring long-term stability of the drug and material, and navigating the complex regulatory pathway for drug-device combination products [38] [30]. Future research is likely to focus on "smart" stimuli-responsive systems and further personalization of therapy.

PHEMA as a Platform for Sustained and Controlled Ophthalmic Drug Delivery

Poly(2-hydroxyethyl methacrylate), or pHEMA, hydrogels have emerged as a leading biomaterial platform for sustained and controlled ophthalmic drug delivery. This application note details the fundamental properties of pHEMA that make it suitable for contact lens-based drug delivery, provides quantitative data on drug release kinetics for various therapeutic agents, and outlines standardized experimental protocols for researchers developing ophthalmic drug delivery systems. By integrating drug delivery functionality directly into contact lens materials, pHEMA-based systems address critical limitations of conventional eye drops, including poor bioavailability and rapid precorneal clearance, thereby enabling more efficient and patient-friendly ocular therapies.

Poly(2-hydroxyethyl methacrylate) is a synthetic hydrogel that has revolutionized ophthalmic applications since its development by Wichterle and Lim in 1960 [42]. Its unique properties—including excellent biocompatibility, transparency, mechanical stability, and ability to absorb and retain significant amounts of water—make it particularly suitable for contact lens applications and drug delivery systems [43]. The three-dimensional cross-linked network structure of pHEMA allows for the encapsulation of therapeutic agents and their subsequent controlled release onto the ocular surface, addressing fundamental challenges in ocular pharmacology [42].

Conventional ophthalmic formulations like eye drops suffer from extremely low bioavailability (typically less than 5%) due to rapid precorneal loss through tear drainage and nasolacrimal removal [44]. By serving as a drug-reservoir in direct contact with the eye, pHEMA-based contact lenses can significantly extend drug residence time and improve corneal penetration, thereby enhancing therapeutic efficacy while reducing systemic side effects [45]. This application note provides a comprehensive framework for utilizing pHEMA as a platform for sustained and controlled ophthalmic drug delivery, with specific protocols and data to support research and development activities.

Key Properties and Advantages of pHEMA

Fundamental Material Characteristics

pHEMA possesses several intrinsic properties that make it ideal for ophthalmic drug delivery applications:

Biocompatibility and Safety: pHEMA elicits minimal immunological response and demonstrates excellent tissue compatibility, as evidenced by its long history of safe use in contact lenses [43]. In vivo safety evaluations in rabbit models showed no ocular irritation or pathological changes during 7-day wearing periods [45].

Optical Properties: pHEMA hydrogels maintain high optical transmittance (>90%), ensuring unimpaired vision when used as drug-eluting contact lenses [45] [27].

Hydration and Stability: pHEMA can absorb 38-42% water by weight while maintaining dimensional stability, creating an aqueous environment suitable for hydrating water-soluble ophthalmic drugs [43] [21].

Tunable Physicochemical Properties: The cross-linking density, polymer molecular weight, and composition can be modified to control mesh size, swelling behavior, and drug release kinetics [46] [42].

Functional Advantages for Drug Delivery

The functional benefits of pHEMA for ophthalmic drug delivery include:

Extended Release Profiles: pHEMA matrices enable sustained drug release over periods ranging from hours to days, compared to minutes with conventional eye drops [45] [44].

Enhanced Bioavailability: By maintaining therapeutic drug levels at the corneal surface, pHEMA systems significantly improve drug bioavailability [45].

Multi-Functional Capability: pHEMA can be engineered to provide additional functionalities such as UV-blocking [45] and antioxidant activity [45].

Stimuli-Responsive Formulations: Incorporation of pH-sensitive monomers like 2-(dimethylamino) ethyl methacrylate (DMAEMA) enables intelligent drug release triggered by specific ocular conditions [46].

Quantitative Drug Release Profiles from pHEMA Systems

The following tables summarize experimental data for various drug-loaded pHEMA systems, demonstrating the range of release profiles achievable through material engineering.

Table 1: Controlled Release Kinetics of Ophthalmic Drugs from pHEMA Hydrogels

| Therapeutic Agent | Drug Class | Release Duration | Cumulative Release | Key Release Parameters | Reference |

|---|---|---|---|---|---|

| Levofloxacin | Antibiotic | 120 hours | 84.2% | Zero-order kinetics | [45] |

| Pilocarpine Nitrate | Miotic | 24 hours | ~70% | Cross-linking dependent | [44] |

| Cytarabine (ara-C) | Anticancer | Initial linear phase | Fickian diffusion | Temperature dependent | [47] |

| Tetrahydrozoline | Vasoconstrictor | 12 hours | Variable | Molecular weight dependent | [46] |